Natural gas melting carbonate fuel cell generation system

A molten carbonate, fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problem that the proportion of MCFC cathode gas cannot be met, the natural gas conversion rate cannot be further improved, and the catalyst activity is decreased. and other problems to achieve the effect of avoiding local temperature increase, reducing equipment cost and simplifying the hydrogen production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

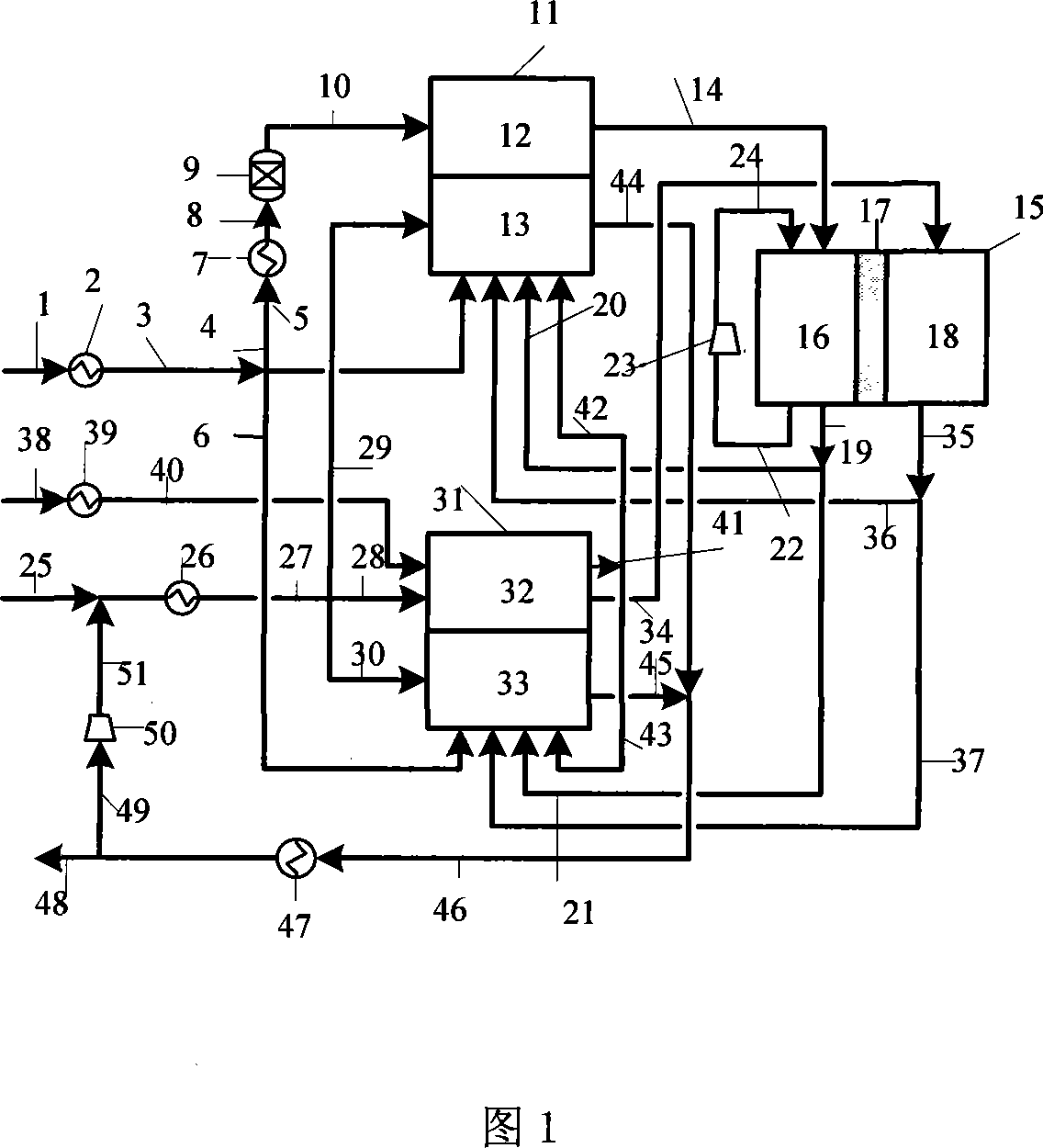

[0024] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0025] The three subsystems are: Adsorption Enhanced Steam Methane Reforming Subsystem, Molten Carbonate Fuel Cell Subsystem, Carbon Dioxide and Tail Gas Recycling Subsystem; Adsorption Enhanced Steam Methane Reforming Subsystem is connected with molten carbonate fuel through the outlet pipe The inlet pipe of the battery subsystem is connected, and the molten carbonate fuel cell subsystem is connected with the inlet pipe of the adsorption-enhanced steam methane reforming subsystem through an outlet pipe. This closed loop structure constitutes a carbon dioxide and tail gas recycling subsystem.

[0026] In the adsorpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com