Method of preparing high-purity nano skutterudite thermoelectricity compound powder by non-water coprecipitation

A technology of skutterudite and co-precipitation, which is applied in the field of preparation of nano-skutterudite thermoelectric compound powder, can solve the problems of poor repeatability, inability to effectively reduce thermal conductivity, and large particle size of nano-powder, and achieve easy Effects of handling, narrow particle size distribution range, fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

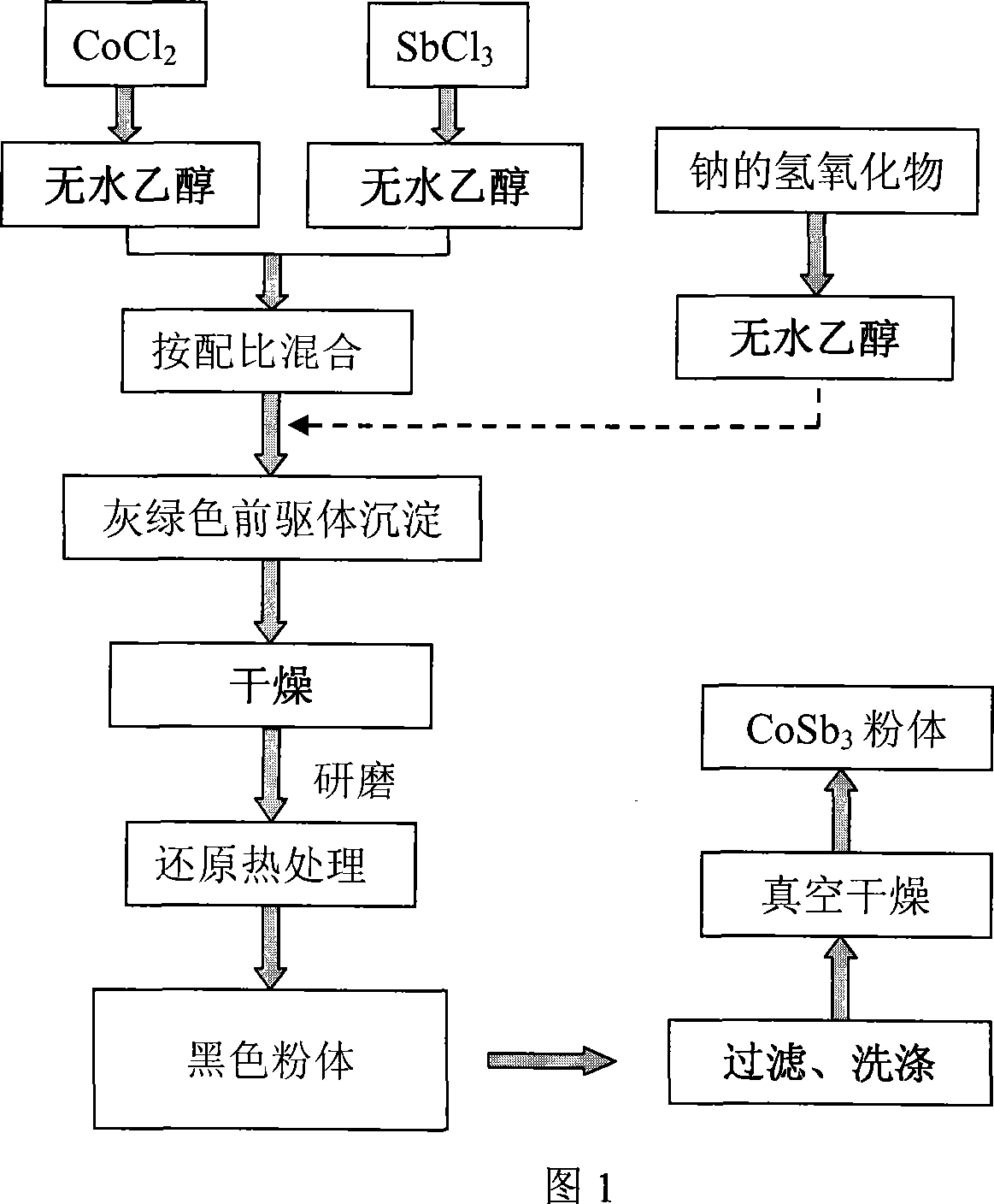

[0022] Embodiment 1: (preparation of CoSb 3 compound nanopowder)

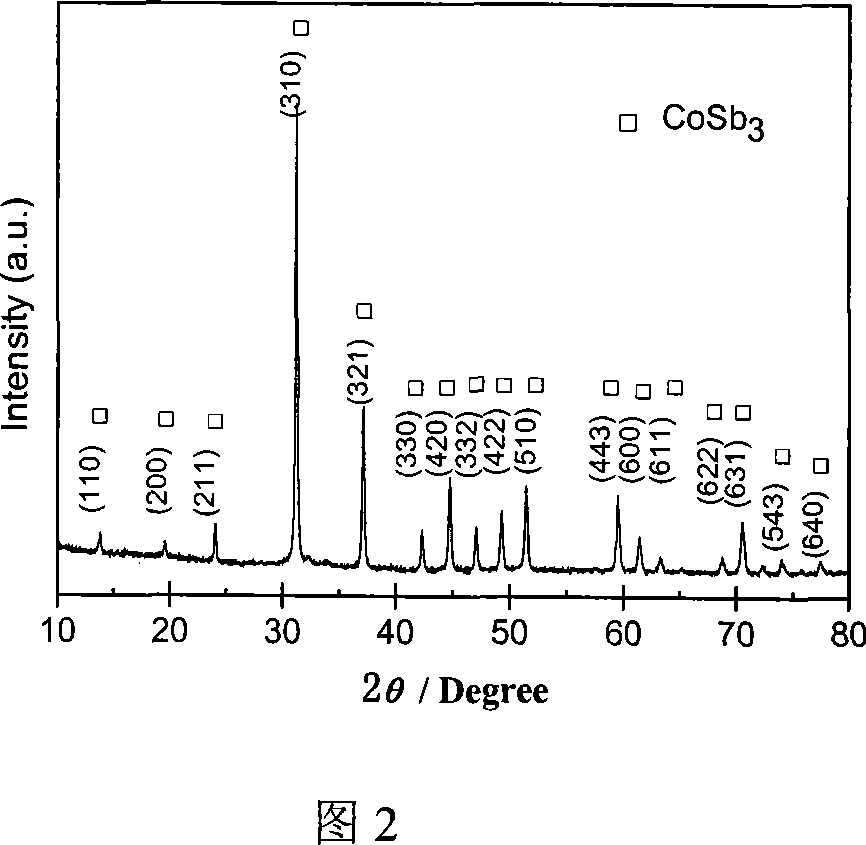

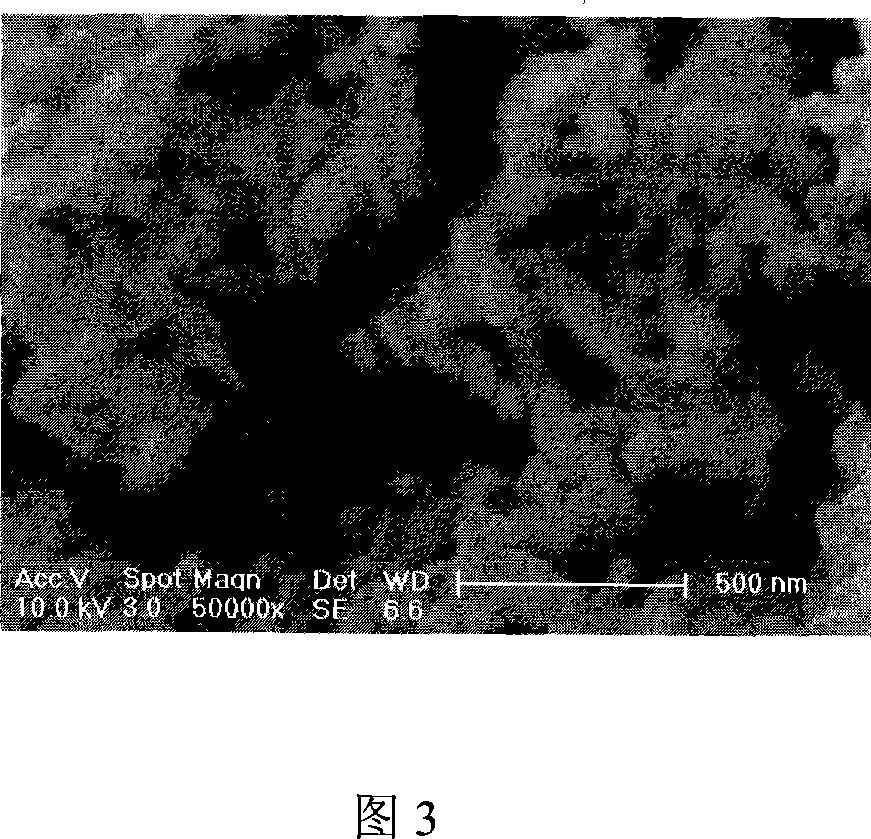

[0023] As shown in Figure 1, with 1.4276g CoCl 2 ·6H 2 O and 4.1061 g SbCl 3 As the initial raw material, it was dissolved in 70ml absolute ethanol solution to form A solution; 4.3821g NaOH was used as precipitating agent, dissolved in 50ml absolute ethanol solution to form B solution. Slowly add solution B to solution A while stirring to produce very fine gray-green precipitates, and obtain a precursor mixed solution containing precipitates. The precursor mixed solution containing the precipitate was directly dried and ground into a powder, and then the ground powder was placed in a tube atmosphere furnace, under H 2 Under the atmosphere, heat up to 300-600°C for reduction heat treatment. After holding time for 0.5-3h, cool with the furnace. The obtained powder (black powder) is filtered with deionized water, washed, and vacuum-dried to obtain nano-square cobalt Mineral compound powder. Fig. 2 is the X-r...

Embodiment 2

[0024] Embodiment 2: (preparation of Ni 0.5 co 3.5 Sb 12 compound nanopowder)

[0025] With 0.1782g NiCl 2 ·6H 2 O, 1.2491 g CoCl 2 ·6H 2 O and 4.1060 g SbCl 3 As the initial raw material, it was dissolved in 70ml absolute ethanol solution to form A solution; 4.3653g NaOH was used as a precipitating agent, dissolved in 50ml absolute ethanol solution to form B solution. Slowly add solution B to solution A while stirring to produce very fine gray-green precipitates, and obtain a precursor mixed solution containing precipitates. The precursor mixed solution containing the precipitate was directly dried and ground into a powder, and then the ground powder was placed in a tube atmosphere furnace, under H 2 Under the atmosphere, heat up to 300-600°C for reduction heat treatment. After holding time for 0.5-3h, cool with the furnace. The obtained powder is filtered with deionized water, washed, and vacuum-dried to obtain high-purity nano-skutterudite Ni. 0.5 co 3.5 Sb 12 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com