Method of preparing intelligent aqueous gel capable of directional moving in electric field

A directional movement and hydrogel technology, applied in the field of intelligent polymer material preparation, can solve the problem of rare double-layer hydrogel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

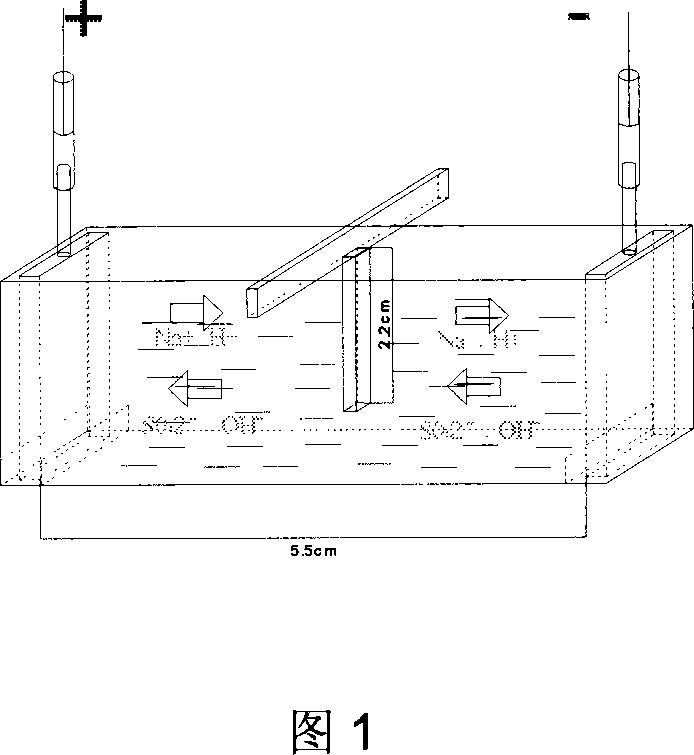

Method used

Image

Examples

Embodiment 1

[0029] The present invention has prepared 6 different splines according to different ratios of acrylamide and acrylic acid, and the specific methods are as follows:

[0030] (1) Dissolve the distilled acrylic acid monomer with water to a concentration of 30 mg / ml, and adjust the pH value to 7.0 with NaOH solution.

[0031] (2) Use the mold mentioned above and put it into the acrylic solution;

[0032] (3) Weigh 0.13g crosslinking agent N, N-methylenebisacrylamide (BAAm) and 0.3g catalyst N, N, N', N'-tetramethylethylenediamine (TEMED) respectively, put In the solution of acrylic acid, the strength of the hydrogel can be controlled by controlling the amount of BAAm;

[0033] (4) Evacuate the container and fill it with nitrogen. Weigh 0.4g initiator ammonium persulfate (APS) in a beaker, add distilled water to make a solution;

[0034] (5) Inject the APS solution into the previous reaction solution, and react in a water bath at 40-60° C. for 12 hours. After the reaction, gen...

Embodiment 2

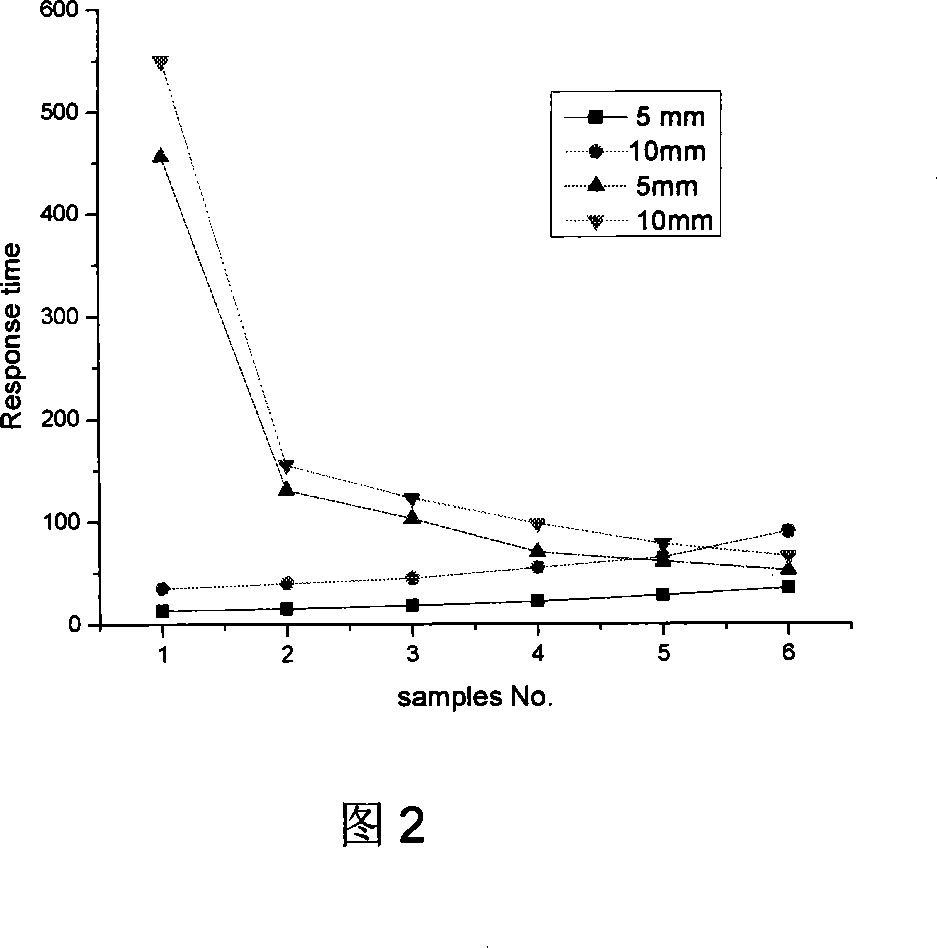

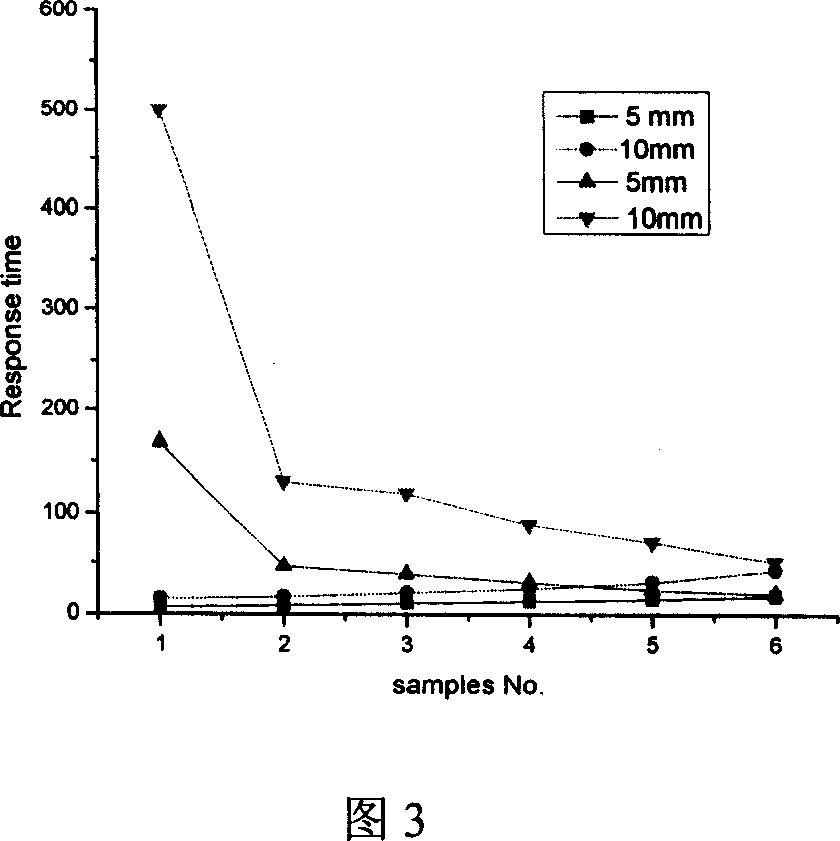

[0037] Under the action of the electric field, the PAA / PAAm double-layer hydrogel sample quickly bends towards the negative electrode at the end, and reaches the equilibrium position within tens of seconds. The side close to the positive electrode swells obviously, and a large amount of gas is generated on the two electrodes. After removing the electric field, the bent gel slowly returned to its original straight shape. As shown in Figure 2 and Figure 3, the PAA / PAAm double-layer hydrogel samples 1-6 are bent towards the negative electrode under the electric field strength of 100V / m and 200V / m, when the horizontal distance of the deviation reaches 10mm and 5mm (represented by the box and the origin respectively), and the time required for them to return to their original positions (represented by the upper triangle and the lower triangle). Comparing the two figures, it is found that the greater the electric field intensity, the shorter the response time of the gel, that is, th...

Embodiment 3

[0040] Subsequently, we studied the change of deformation of sample No. 5 under a periodic electric field, as shown in Figure 5. It is not difficult to see from Figure 5 that when the PAA / PAAm bilayer hydrogel is under a periodic electric field, its response rate does not change with the number of times the applied electric field increases. This experiment shows that the PAA / PAAm bilayer hydrogel is reusable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com