Phosphorus-nitrogen type halogen-free ionic fire retardant, preparation method thereof and fire retarding polyvinyl alcohol material prepared from the same

A polyvinyl alcohol and flame retardant technology, which is applied in the direction of fire retardant coatings, etc., can solve the problems of affecting the mechanical properties and other properties of materials, adding a large amount of flame retardants, increasing material costs, etc., to avoid harm to the human body, water solubility Good performance and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

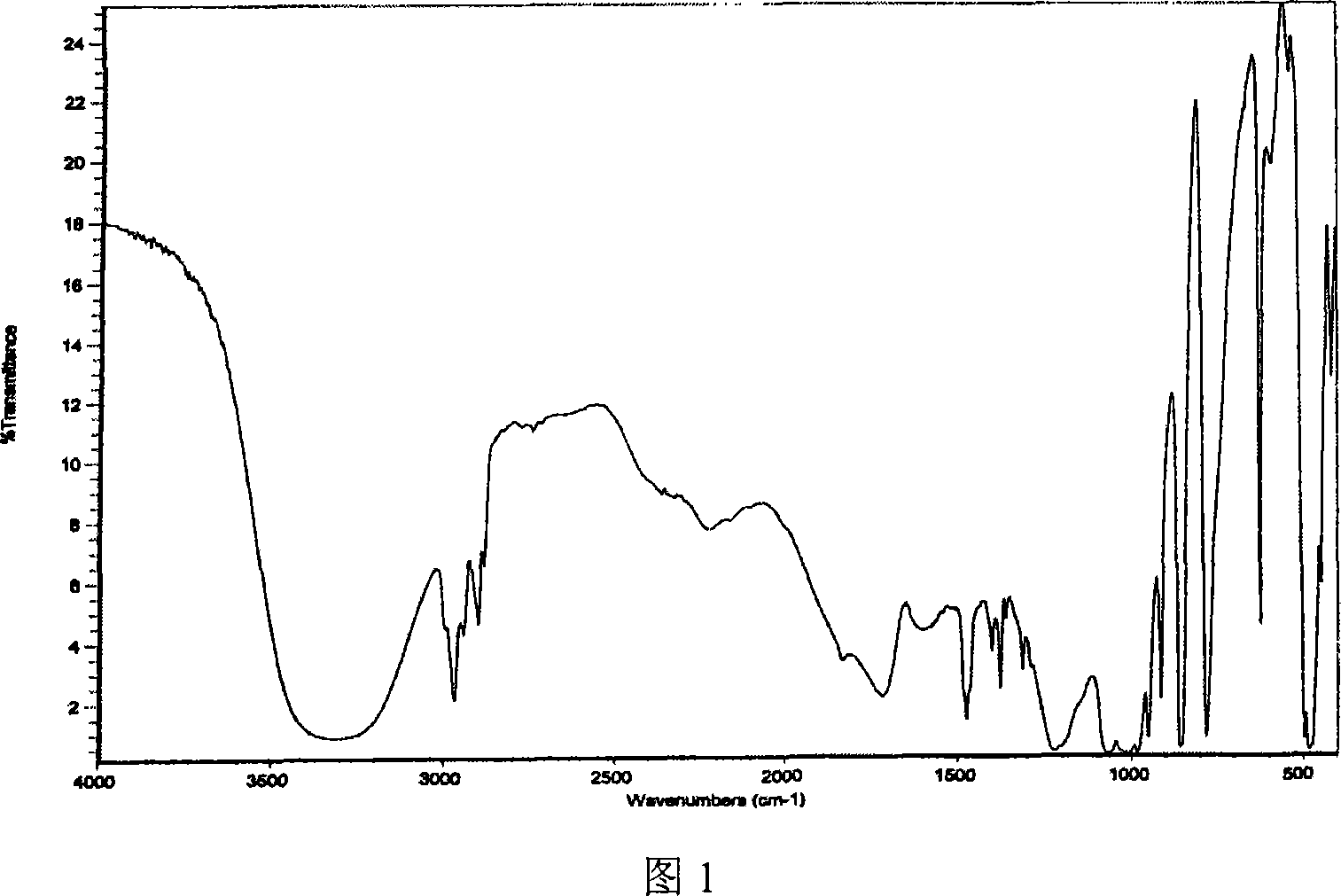

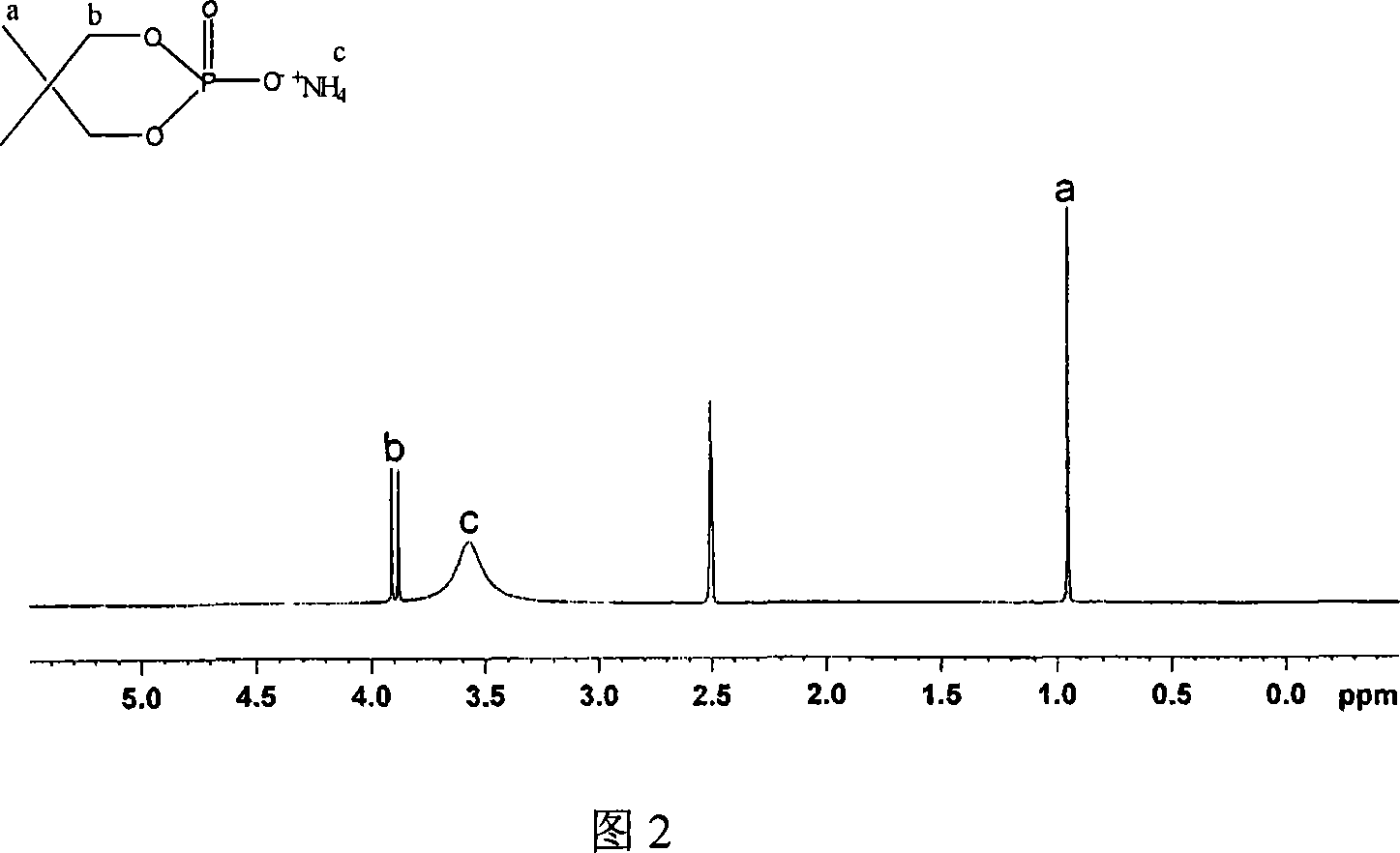

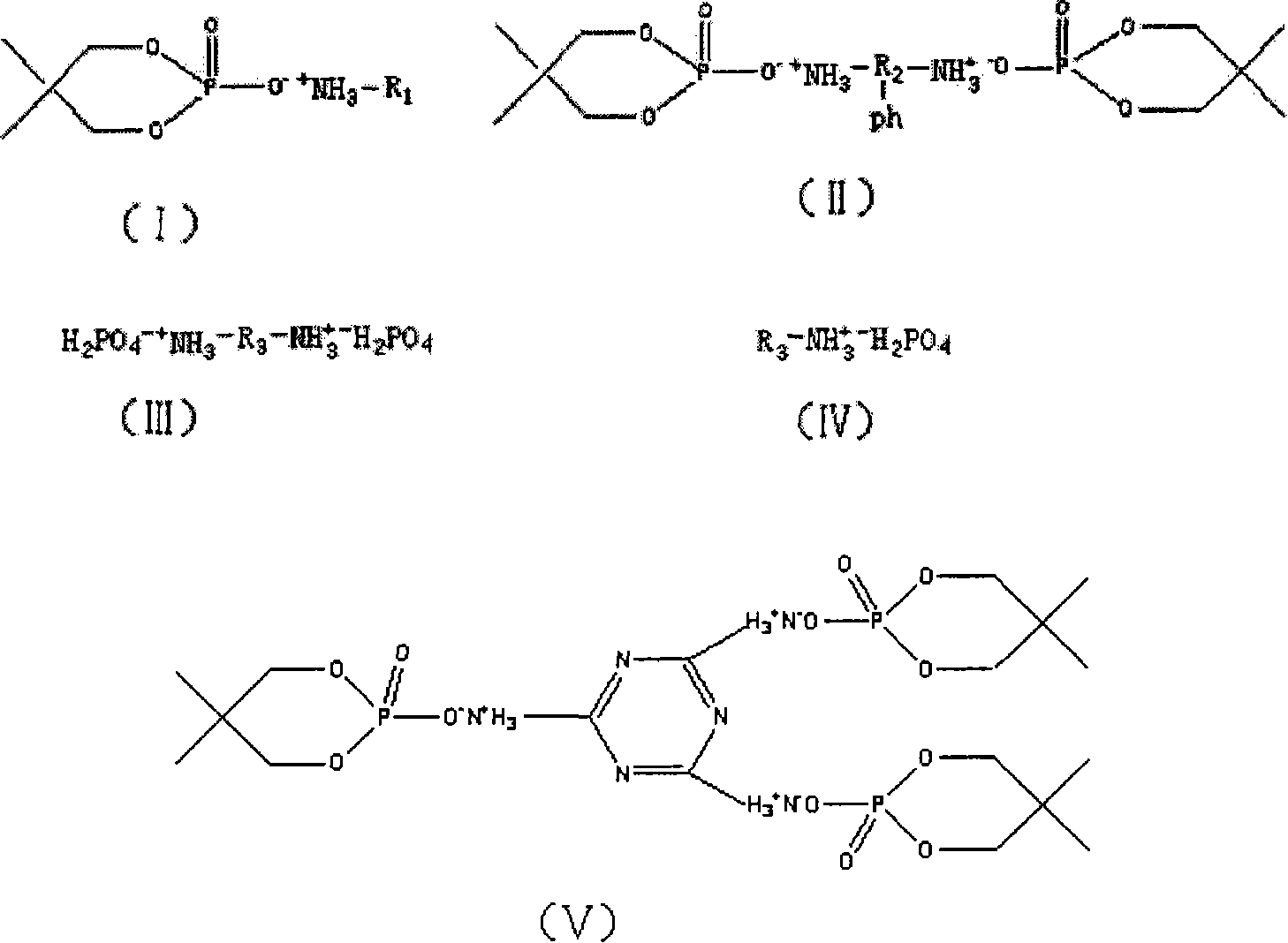

Method used

Image

Examples

Embodiment 1

[0041] Dissolve 16.6g (0.1mol) of 1,2-dimethyl 1,3-propanediol phosphoric acid in 16.6ml of water and reflux for 1.0 hour, cool down to 70°C, then add 5.0ml (0.14mol) of ammonia water dropwise, and heat to reflux After 2.5 hours, cool, crystallize and filter to obtain a solid ionically bonded P-N type flame retardant (I) with a melting point of 232°C.

[0042] First, 15.0% of P-N type flame retardant (I), 15.0% of melamine were stirred at a temperature of 90°C to make it fully dissolved in 80ml of water, and then 0.3% of NiSAO and 69.7% of PVA (0588) were added. After stirring for 3.0 hours at a constant temperature of ℃, ultrasonic dispersion for 30 minutes is enough.

Embodiment 2

[0044] Dissolve 16.6g (0.1mol) of 1,2-dimethyl 1,3-propanediol phosphoric acid in 35.0ml of water and reflux for 0.5 hours, cool down to 80°C, and then add 10.8g (0.1mol) of p-phenylenediamine, Heat to reflux for 2.0 hours, cool, crystallize and filter to obtain a solid ionically bonded P-N type flame retardant (II) with a melting point of 242°C.

[0045] Stir 7.5% of P-N type flame retardant (II) and 15.0% of melamine phosphate at a temperature of 90°C to fully dissolve them in 80ml of water, then add 1.0% of CuSA and 76.5% of PVA (0588) , stirred at 85°C for 3.0 hours, then ultrasonically dispersed for 30 minutes.

Embodiment 3

[0047] Dissolve 16.6g (0.1mol) of 1,2-dimethyl 1,3-propanediol phosphoric acid in 75.0ml water and reflux for 0.5 hours, cool down to 80°C, then add 0.06mol sulfonamide dropwise, heat and reflux for 0.5 hours, cool The solid ion bonded P-N type flame retardant (II) with a melting point of 108° C. was obtained by crystallization and filtration.

[0048] Stir 7.5% of P-N type flame retardant (II) and 7.5% of melamine phosphate at a temperature of 90°C to fully dissolve them in 80ml of water, then add 0.5% of CoSA and 84.5% of PVA (1788) , Stir and blend at 90°C for 3.0 hours, then ultrasonically disperse for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com