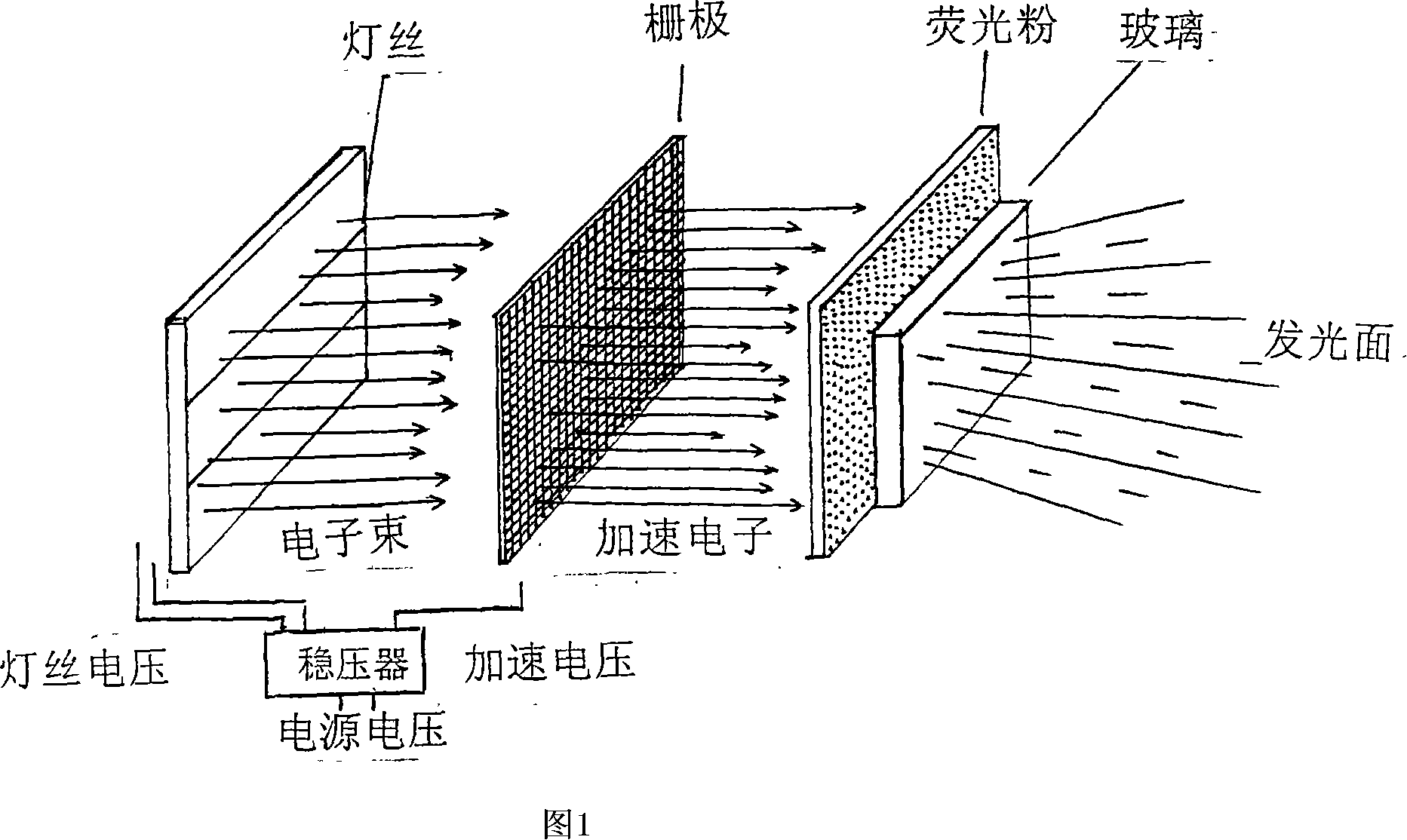

Direct heating cathode electron excitation fluorescent lamp working principle and its manufacture method

A technology of electronic excitation and manufacturing method, applied in the direction of lamp parts, etc., can solve the problems of high cost, poor spectral color rendering, low luminous efficiency, etc., and achieve the effect of high efficiency and high luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

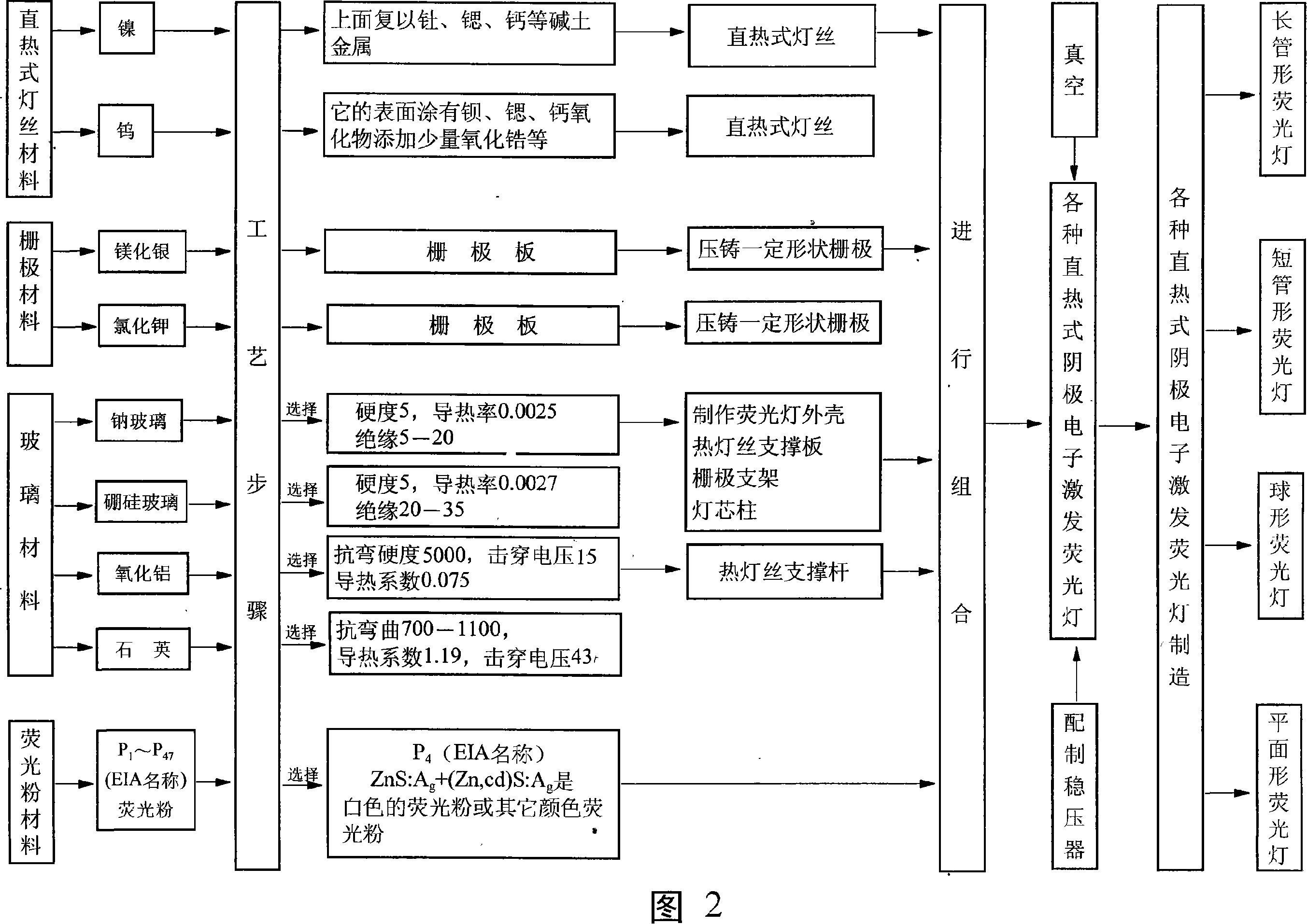

[0048] The base metal direct-heating filament is made of nickel, which is covered with alkaline earth metals such as thorium, strontium, and calcium, or the direct-heating filament is made of tungsten, and its surface is coated with oxides of barium, strontium, and calcium as the main components.

[0049] The grid plate of the secondary electron emission material is made by using silver magnesium oxide or alkali halide layer such as potassium chloride.

[0050] Kovar metal material is used to make all the leads needed in the fluorescent lamp.

[0051] To use a getter, a small flake of getter is deposited in one corner of the lamp for all fluorescent lamps of manufacture and method as with electron tubes.

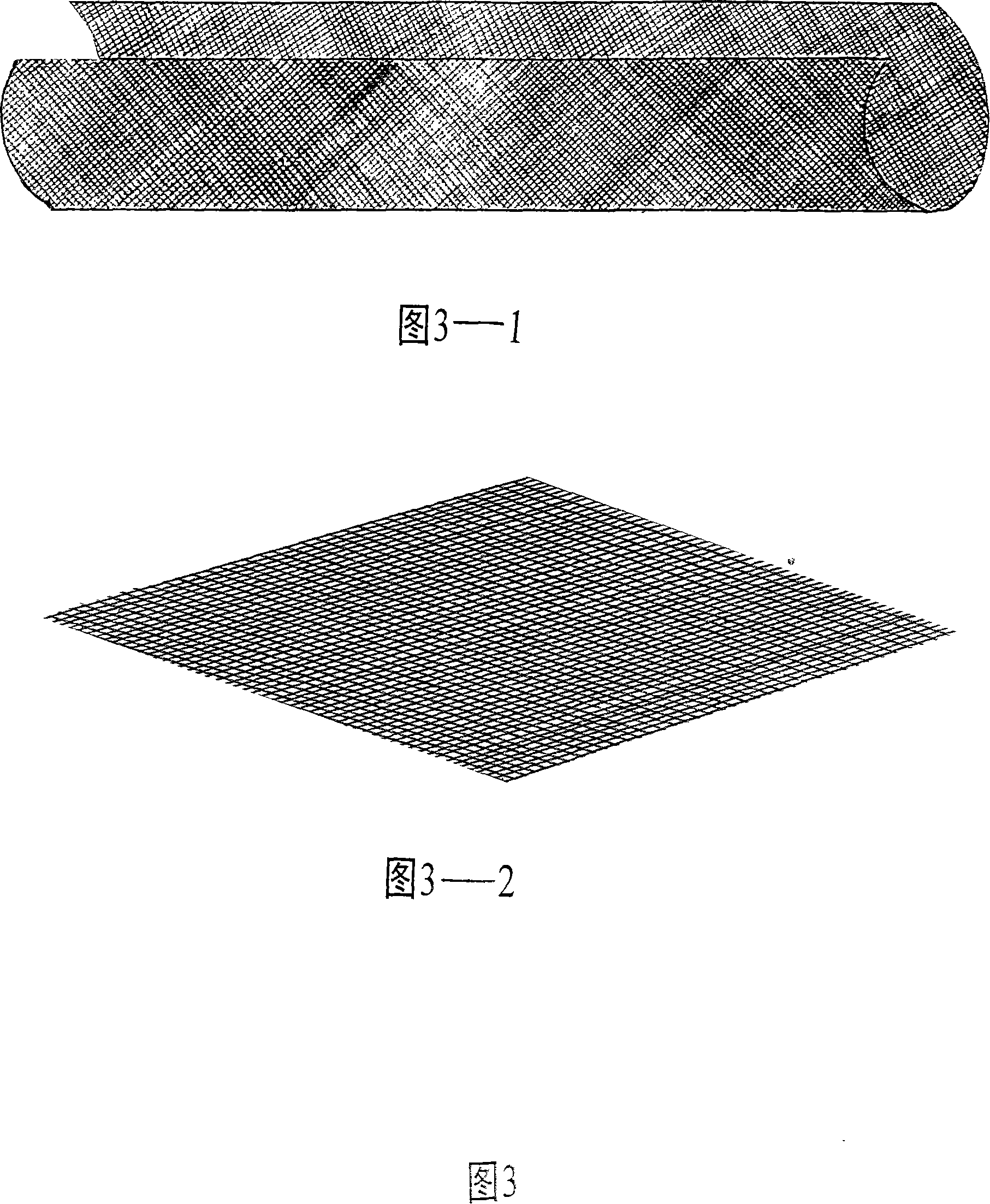

[0052] In Figure 3-1, the grid plate is die-cast into a long tubular shape, and in Figure 3-2, the grid plate is die-cast into a planar shape.

[0053] In Figure 4-1, soda glass is used to make the grid support, the front shape (1), the three-dimensional shape (2), the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com