Energy-saving control device for beam pumping unit

An energy-saving control and beam-type technology, which is applied in the direction of circuit devices, emergency protection circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, etc. Low power factor of the system, excessive loss of low-voltage distribution lines, etc., achieve the effect of automatically tracking the change of reactive power, saving active power, and increasing the excitation potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

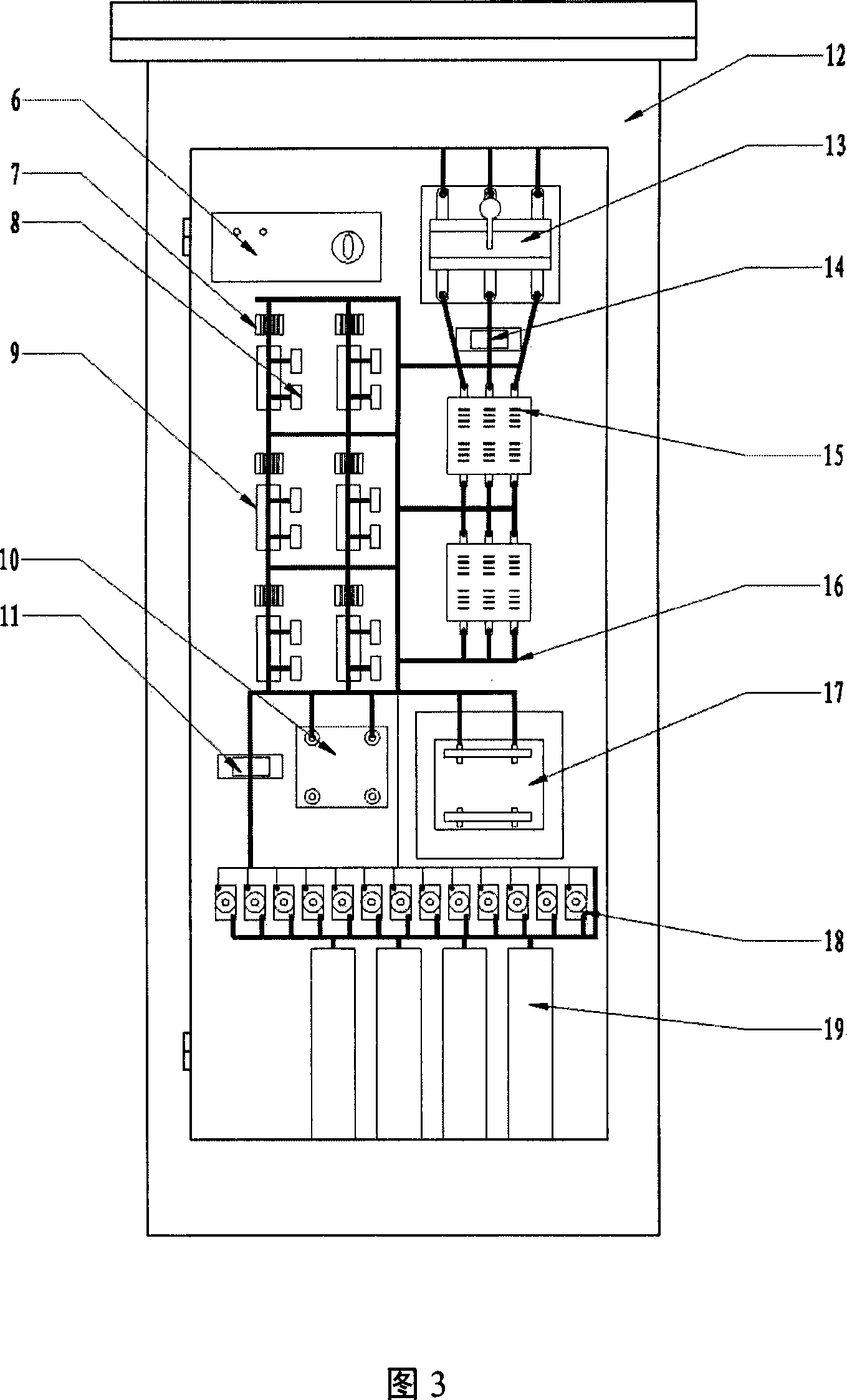

[0040]As shown in Fig. 3, Fig. 3 is a schematic diagram of the internal structure of the energy saving control device of the present invention. The energy-saving control device according to the present invention includes a thyristor switching capacitor and its controller. A triangular compensation circuit is connected in parallel at the outlet end of the motor. There are three components of a thyristor, a reactor and a compensation capacitor on each side of the triangle. The thyristor is composed of The controller detects the current state of the outlet terminal of the motor to control whether it is switched on or not. Specific devices include controller 6, SCR driver 7, voltage equalizing resistor 8, thyristor 9, transformer 10, current transformer A11, cabinet 12, circuit breaker 13, current transformer B14, AC contactor 15, primary power distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com