Titanium oxide and alumina alkali metal compositions

A technology of oxides and compositions, applied in the field of porous metal oxide compositions, can solve the problems of incomplete mixing and not suitable for preparing Na/TiO2 and Na/NaCl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1: Exemplary Porous Metal Oxide. Calcination of porous TiO by Sachtleben Chemie in air at 600 °C 2 (Anatase) (29.5nm diameter pores, or 295_) and activated porous alumina of Almatis AC (358m 2 / g), and then cooled to room temperature. To these powders in a helium-filled glove box was added dropwise liquid Na 2 K onto the porous oxide in a stainless steel pan. The liquid alloy is quickly absorbed into the porous metal oxide. As long as the total concentration of metals does not exceed 30 wt%, the white powder becomes dark black in color and the mixture becomes a uniform loose powder. This provides a class 0 material sample, as shown in FIG. 5 .

Embodiment 2

[0078] Example 2: A distinctive feature of the Group 1 metal / porous metal oxide compositions of the present invention is their ability to generate pure hydrogen gas when added to water. The "reducing power" of the Group 1 metal / porous metal oxide composition was determined by adding water to the evacuated sample and collecting the hydrogen gas with a modified Toeppler pump. Reducing power is defined as the weight percent of the alkali metal or alloy used to produce the same amount of hydrogen. This was confirmed by collecting hydrogen gas produced by a known mass of material upon reaction with degassed water. Hydrogen gas was collected in a calibrated pipette with a modified Toeppler pump (mercury filled). This analysis was performed on every sample of reduced porous metal oxide, regardless of the grade of material. For example, if a 30 wt% sample of NaK in a class I porous metal oxide produces the same amount of hydrogen as that amount of NaK alone, the reducing power is 30...

Embodiment 3

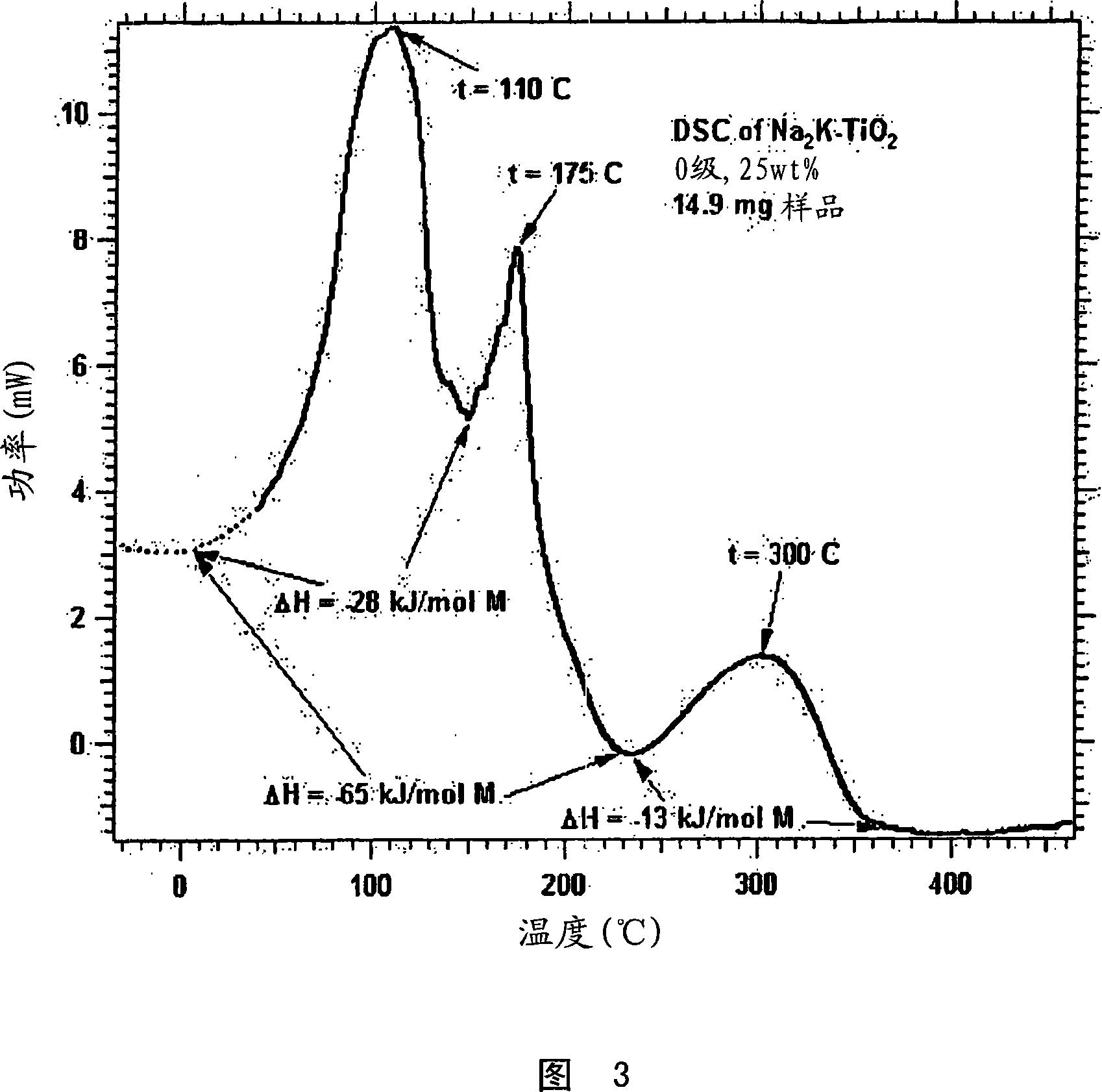

[0079] Example 3: Preparation of Class I materials can be performed by continuously heating Class 0 materials to 150°C or by using higher melting alkali metals such as sodium and potassium. 14.0 g of degassed and calcined porous alumina was weighed and put together with 6.0 g of Na metal into a Parr stainless steel reactor equipped with a Teflon gasket seal. The combination of porous metal oxide and Na was heated while rotating the reactor upside down at 60 rpm, first to 105°C for 1 hour, then at 155°C overnight. The powder is loose, black and free flowing. Transformation 0 grade Na was also carried out 2 K-Al 2 o 3 、Na 2 K-TiO 2 and Na-TiO 2 A similar process to Class I material. For example, the DSC for 21 wt% material is shown in Figure 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com