Combined purification method for effluvial exhaust air

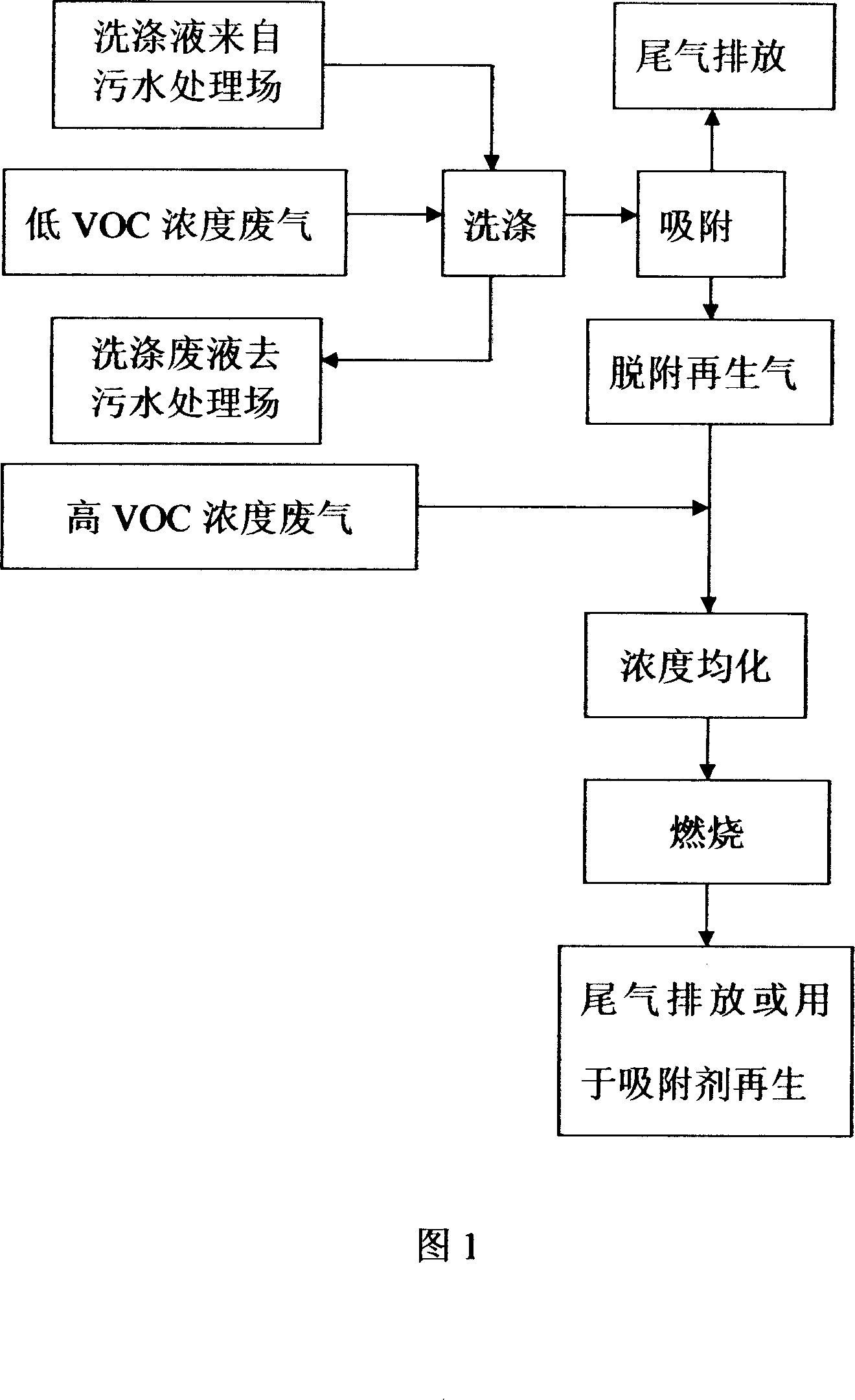

A waste gas purification and odor technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve problems such as the inability to meet the continuous operation requirements of the catalytic combustion device and the unfavorable stable operation of the catalytic combustion device, and achieve high cost and operation. The effect of low cost and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0026] Collect the waste gas produced by the sewage biochemical aeration tank and sludge aging tank of a petrochemical enterprise, and use the sewage discharged by the enterprise for washing treatment in the packed tower. The gas-liquid contact time is 2-5s, and the washing intensity is 3-7L washing liquid / M 3 exhaust gas. The exhaust gas after washing is adsorbed by activated carbon, and the adsorption process uses two adsorbers to switch operations. When the concentration of odor components in the exhaust gas is higher than GB 162976-1996 "Integrated Emission Standards for Air Pollutants" and GB14554-93 "Emission Standards for Odor Pollutants" , local emission standards and other relevant limit values, switch (the specific operation can be determined according to the needs). The volume space velocity of the adsorption process is 1500hr -1 . Desorption regeneration adopts steam regeneration at 250°C, and the space velocity is 50hr -1 . Or use catalytic combustion exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com