Process of preparing asphalt carbon foam material

A technology of carbon foam and asphalt, which is applied in the field of preparation of pitch carbon foam materials, can solve the problems of low compressive strength, uneven structure, and low expansion ratio, and achieve high thermal and electrical conductivity, uniform pore size distribution, and open cell ratio high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put 50g of coal tar pitch into a container, add 50ml of toluene solvent, place it in a high-pressure reactor and seal it, and protect it by vacuuming. Raise the temperature to 300°C at a heating rate of 5°C / min, and keep the temperature for 240min. Lower the temperature to 290°C, then deflate at a rate of 0.05MPa / s, and lower it to room temperature to produce bituminous foam with large porosity and uniform cells. Oxidation at 220°C for 600min, carbonization at 950°C for 120min, and graphitization at 2400°C for 120min, the final pitch foam carbon material can be obtained.

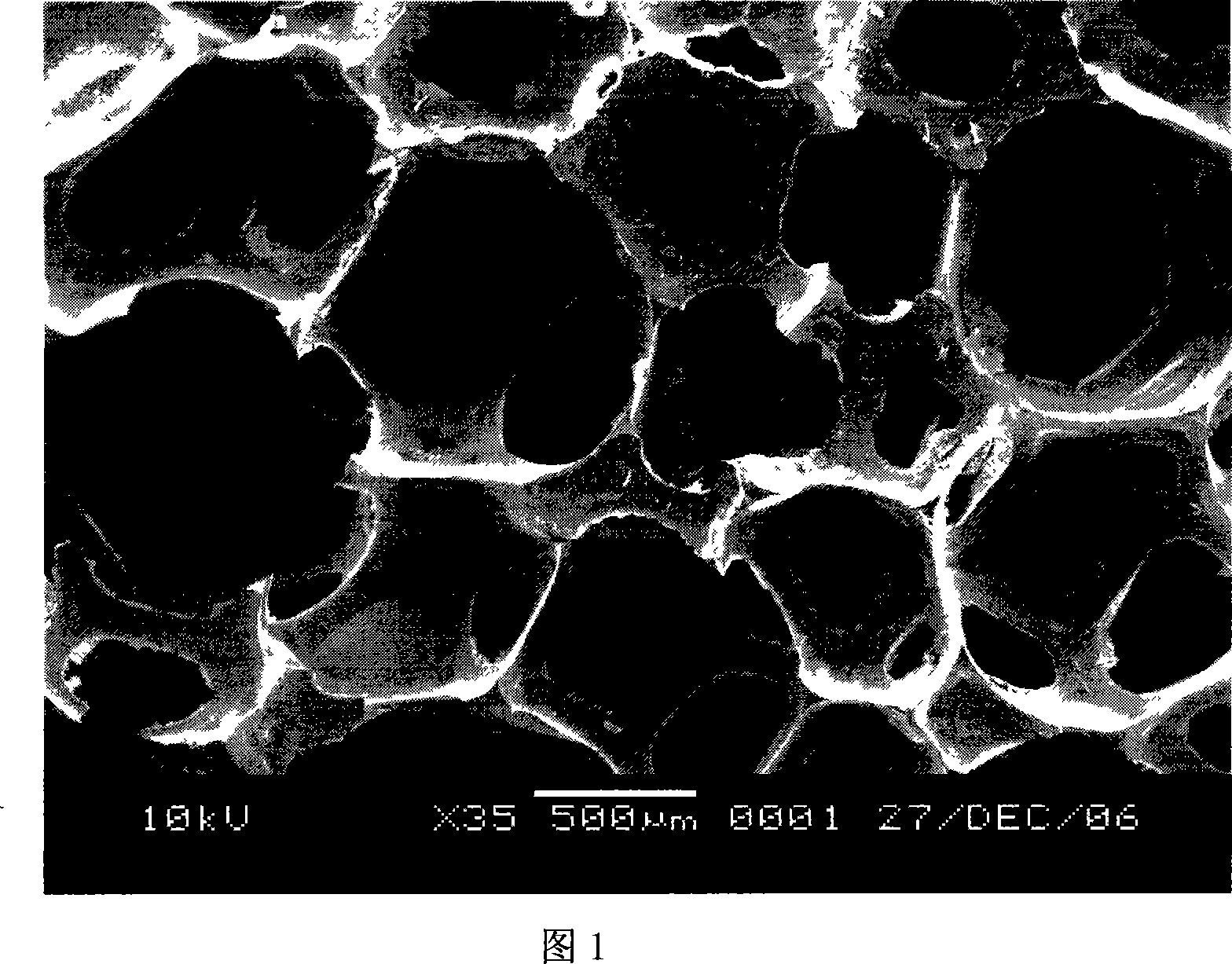

[0031] The prepared pitch foam carbon material has a bulk density of 0.5g / cm 3 , thermal expansion coefficient 5.2ppm / ℃, thermal conductivity 110~150w / mk, specific thermal conductivity 220~250(w / mk) / (g / cm 3 ), the porosity is 84%, and the cell diameter is 500-1000 μm.

Embodiment 2

[0033] Put 50 g of mesophase pitch into a container, add 50 ml of toluene solvent, place it in a high-pressure reactor and seal it, and protect it by vacuuming. Raise the temperature to 320°C at a heating rate of 5°C / min, and keep the temperature for 240min. Lower the temperature to 315°C, then deflate at a rate of 0.05MPa / s, and lower it to room temperature to produce asphalt foam with large porosity and uniform cells. Oxidation at 220°C for 600min, carbonization at 950°C for 120min, and graphitization at 2400°C for 120min, the final pitch foam carbon material can be obtained.

[0034] The prepared pitch foam carbon material has a bulk density of 0.2 to 0.3 g / cm 3 ;The thermal expansion coefficient is 3.5ppm / ℃, the thermal conductivity is 150~220w / mk, and the specific thermal conductivity is 200~240(w / mk) / (g / cm 3 ), the porosity is 90%, and the cell diameter distribution is 90-130 μm.

Embodiment 3

[0036] Put 50 g of mesophase pitch into a container, add 50 ml of toluene solvent, place it in a high-pressure reactor and seal it, and fill it with nitrogen for protection. Set the initial pressure to 3MPa, raise the temperature to 320°C at a heating rate of 5°C / min, and keep the temperature for 240min. Lower the temperature to 315°C, then deflate at a rate of 0.5 MPa / s, and lower it to room temperature to produce asphalt foam with large porosity and uniform cells. Oxidation at 220°C for 600min, carbonization at 950°C for 120min, and graphitization at 2400°C for 120min, the final pitch foam carbon material can be obtained.

[0037] The prepared pitch foam carbon material has a bulk density of 0.2 to 0.3 g / cm 3 ;The thermal expansion coefficient is 3.2ppm / ℃, the thermal conductivity is 150~240w / mk, and the specific thermal conductivity is 200~240(w / mk) / (g / cm 3 ), the porosity is 94%, and the average cell diameter is 97±5μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com