Method for promoting preprocessing of copper-clad zirconium tungstate composite powder

A technology of composite powder and zirconium tungstate, applied in the field of pretreatment of powder coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

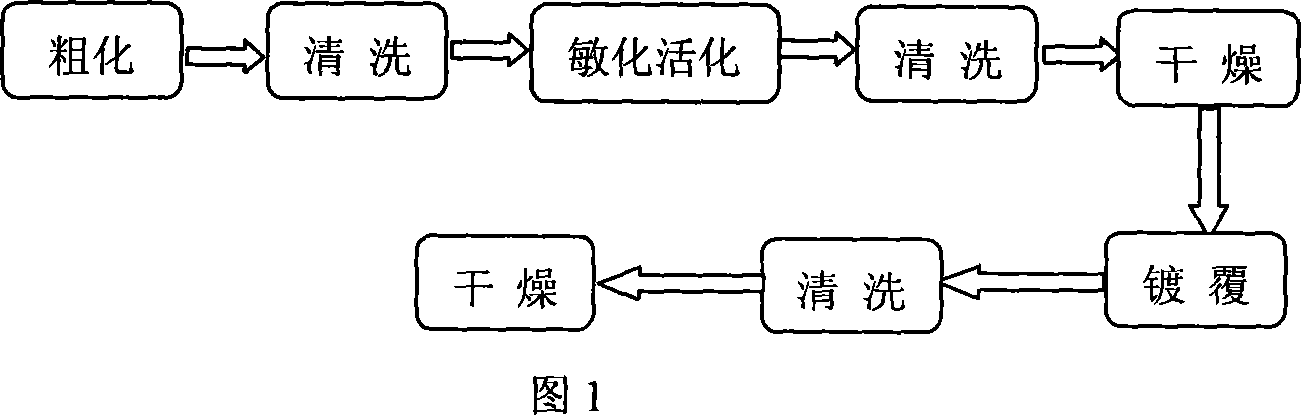

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: (its sensitization activation solution gets 200ml; Plating solution gets 200ml)

[0031] (1) Coarseness: Weigh the prepared ZrW 2 o 8 For the powder, stir with concentrated nitric acid magnetically while heating for about 30 minutes, wash and dry.

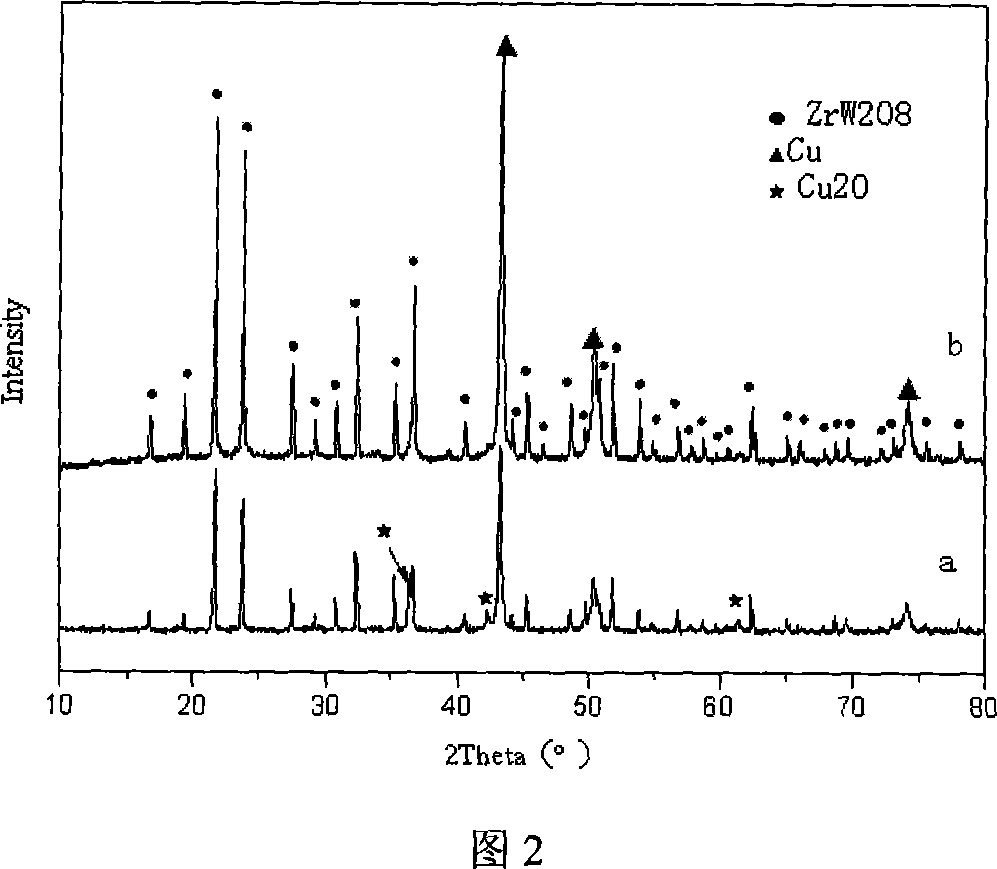

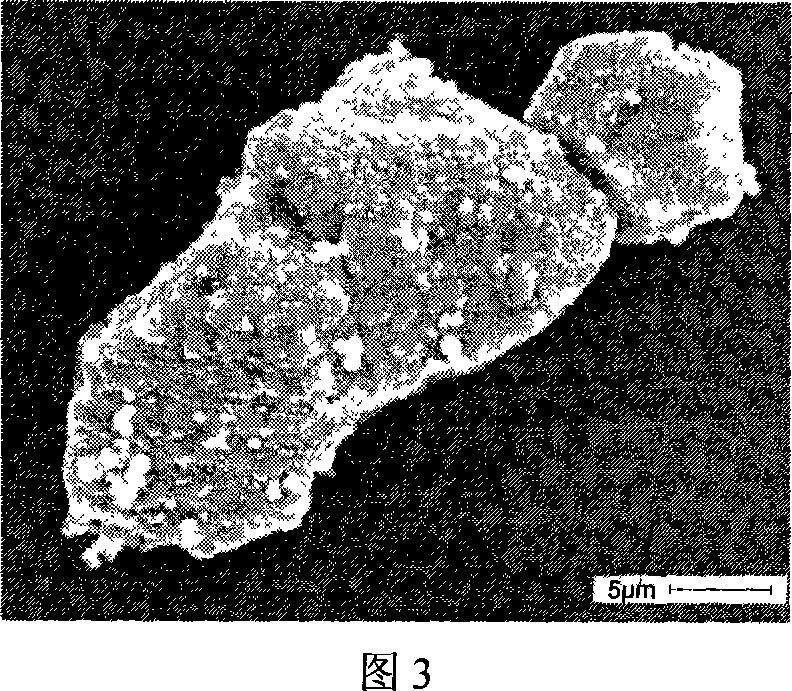

[0032] (2) One-step sensitization and activation: weigh 0.06gPdCl 2 Dissolve in 15ml of hydrochloric acid to obtain solution I, then dissolve 28gNaCl in 100ml of distilled water to obtain solution II, mix solutions I and II to obtain solution III, and then add 6.5g of SnCl 2 Dissolve in 70ml of distilled water to obtain solution IV, add prepared solution III to solution IV, add distilled water to 200ml. Treat 10g of inorganic powder per 100ml of sensitization and activation solution, and the sensitization solution can be reused three times at most, because the Pd ions in the solution are reduced every time the sensitization and activation solution is performed. After 30 minutes of sensitization and activati...

Embodiment 2

[0035] Embodiment 2: (its sensitization activation solution gets 500ml; Plating solution gets 500ml)

[0036] (1) Coarseness: Weigh the prepared ZrW 2 o 8 For the powder, stir with concentrated nitric acid magnetically and heat for about 60 minutes at the same time, then wash and dry.

[0037] (2) One-step sensitization and activation: first weigh 0.2gPdCl 2 Dissolve in hydrochloric acid to obtain solution I, then dissolve 80gNaCl in 250ml distilled water to obtain solution II, mix solutions I and II to obtain solution III, then add 20gSnCl 2 Dissolve in 200ml of distilled water to obtain solution IV, add prepared solution III to solution IV, add distilled water to 500ml. Treat 10g of inorganic powder per 100ml of sensitization and activation solution, and the sensitization solution can be reused three times at most, because the Pd ions in the solution are reduced every time the sensitization and activation solution is performed. After 50 minutes of sensitization and activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com