Continuous micro-filtering filtering pool for water treatment and use therefor

A water treatment and filter technology, applied in permeation/dialysis water/sewage treatment, ultrafiltration, etc., can solve the problems of hygiene water quality defects, high investment in CMF and CMF-S process, and achieve the effect of excellent water quality and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

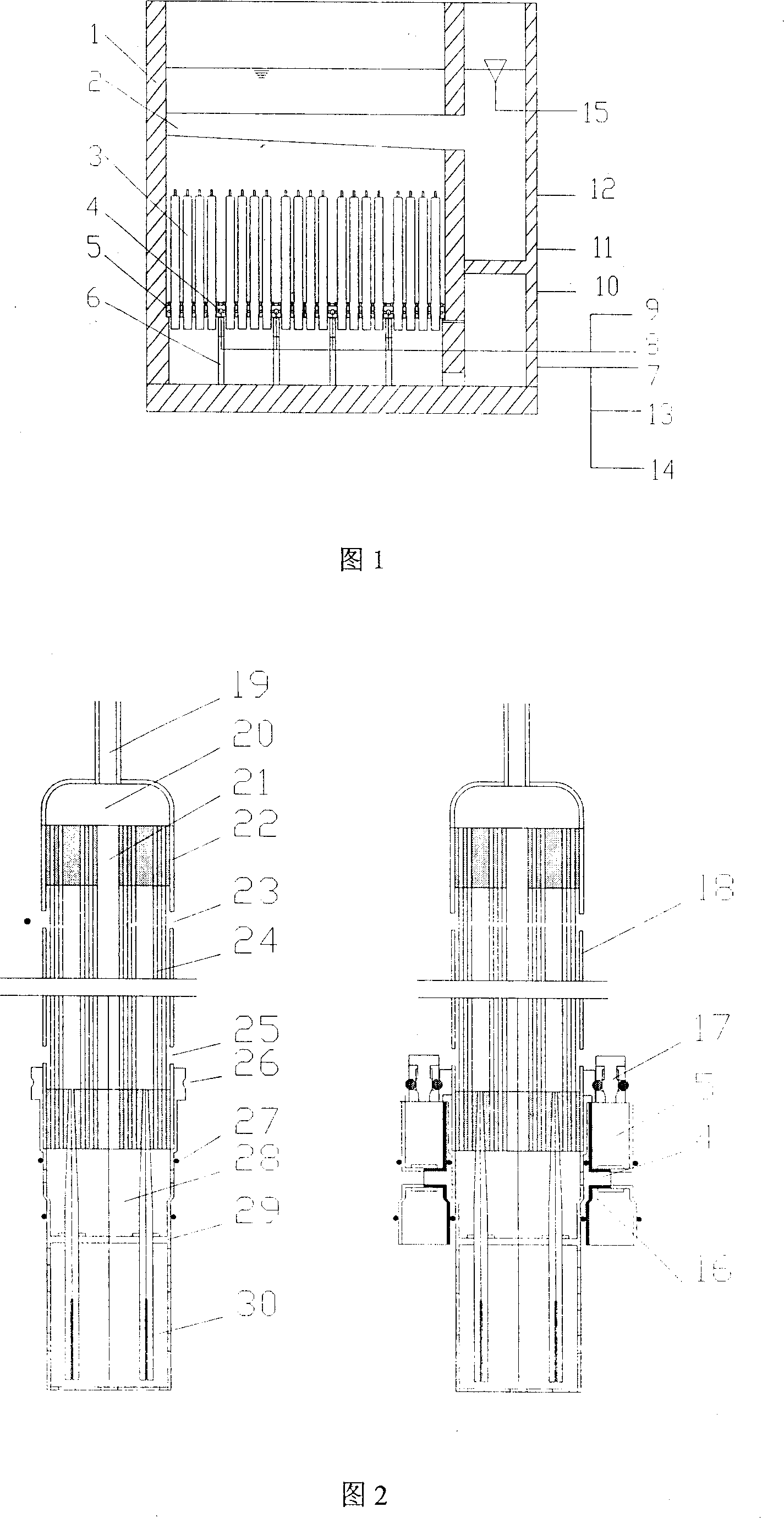

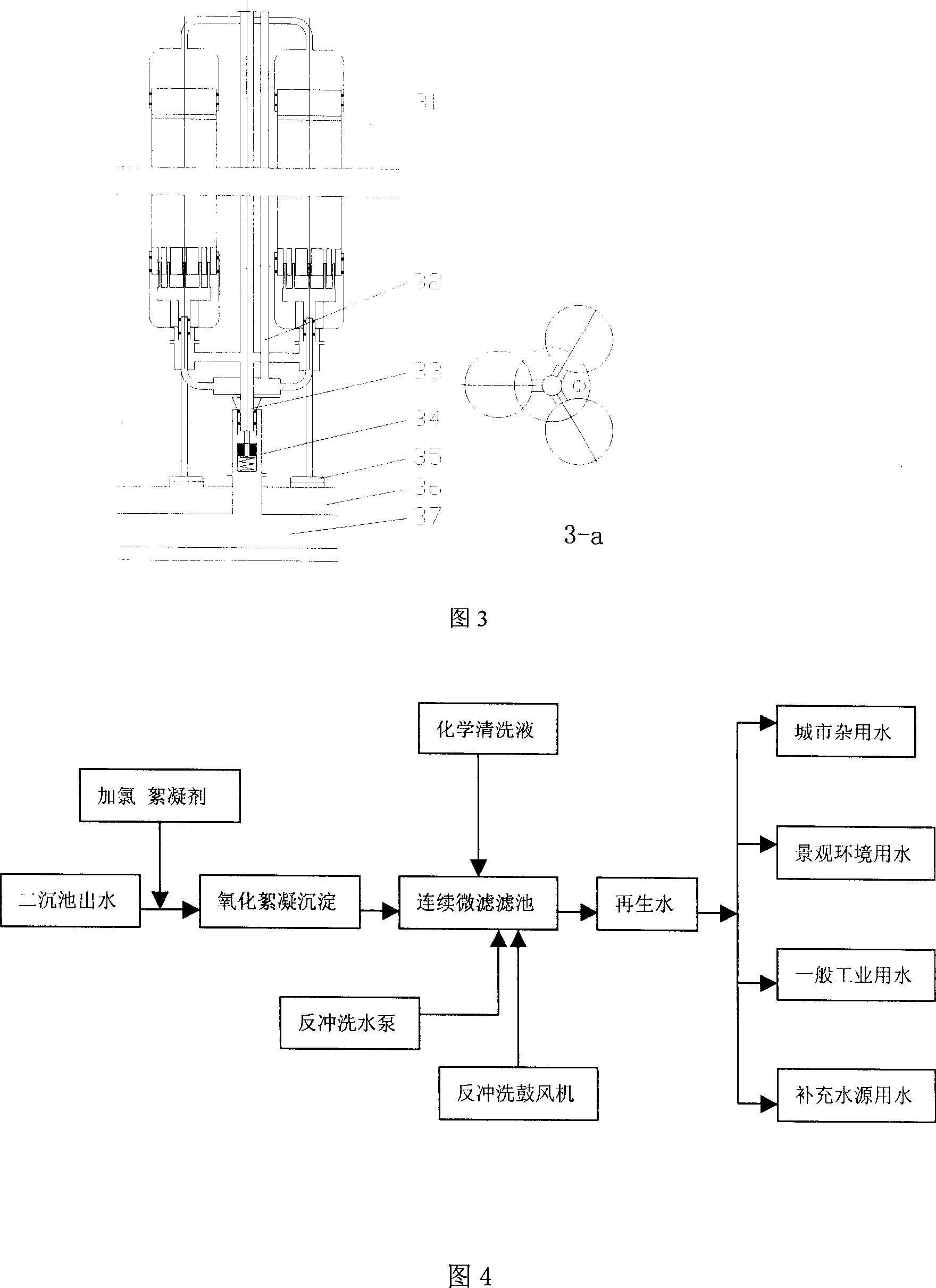

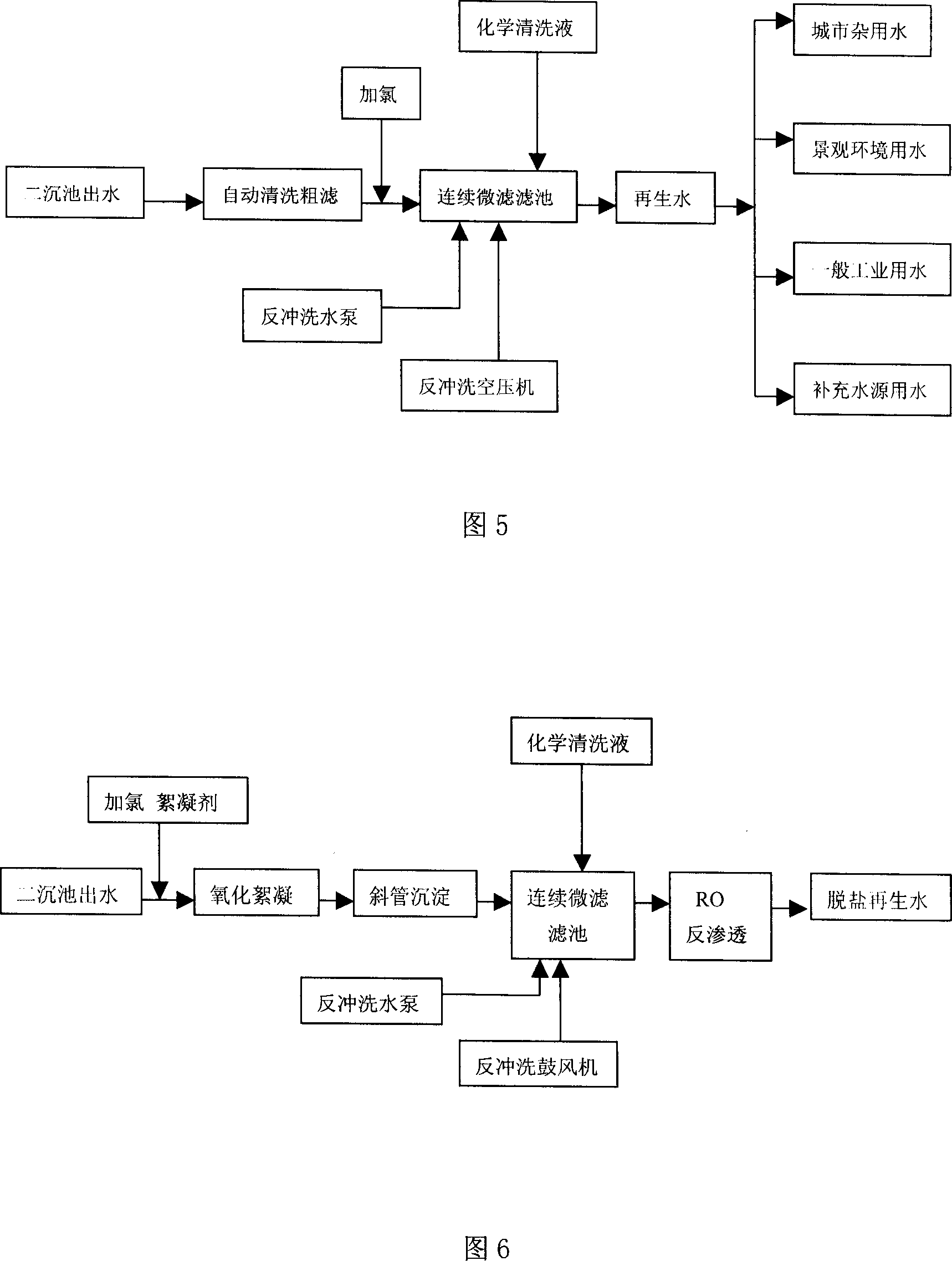

[0035] A continuous microfiltration filter, consisting of microfiltration membrane filter material (single plug-in membrane module or Y-shaped combined plug-in membrane module), reinforced concrete filter tank (or metal filter tank), water collection filter plate, air-water reverse It is composed of flushing system, pickling system, alkali cleaning system and pre-chlorination system. The microfiltration membrane (MF) is an oxidation-resistant PVDF external pressure hollow fiber membrane with a cut-off pore size of 0.2 μm; a gravity-type microfiltration filter with a domestic membrane flux of 30-35L / m 2 ·h; the filtration capacity per unit effective area of the filter is 16-20m 3 / m 2 h. Imported membrane membrane flux 50L / m 2 h, the filtration capacity per unit effective area of the filter can reach 30m 3 / m 2 h. Pressure microfiltration filter, domestic membrane membrane flux 40L / m 2 ·h; the filtration capacity per unit effective area of the filter is 22~27m 3 / ...

Embodiment 2

[0037] A continuous microfiltration filter, the microfiltration membrane filter material (single plug-in membrane module or Y-shaped combined plug-in membrane module) is filled in the reinforced concrete filter tank, and the filter plate supports the membrane module. The size of the filter plate is 1000×1000 (mm), and the gap between the filter plates is sealed with a sealant. The filter plate is supported by the filter wall, the two ends of the filter wall are connected with the filter pool wall, and the root of the filter wall is connected with the pool bottom. There are several air cushion balance pipes with d=25mm on the top of each filter wall, and 2 to 3 hydraulic balance holes of 700×700(mm) at the bottom. The upper part of the filter is provided with a backwash drain pipe and a chemical cleaning water inlet pipe; the lower part of the filter is provided with a water inlet pipe, an outlet pipe, and a backwash water inlet pipe. A pre-filter chlorine addition pipe is pro...

Embodiment 3

[0039] A continuous microfiltration filter, the MF microfiltration membrane has a cut-off pore size of 0.2 μm, 100% of the particles larger than 0.2 μm in the influent are removed, and the diameter of bacteria is greater than 0.2 μm, so the continuous microfiltration filter has excellent sterilization effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com