Method for preparing tungsten hexafluoride gas

A technology of tungsten hexafluoride and gas, which is applied in the field of preparation of tungsten hexafluoride gas, can solve the problems that the purity of tungsten hexafluoride products is difficult to meet the requirements of high-purity gas, high cost, and high purification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

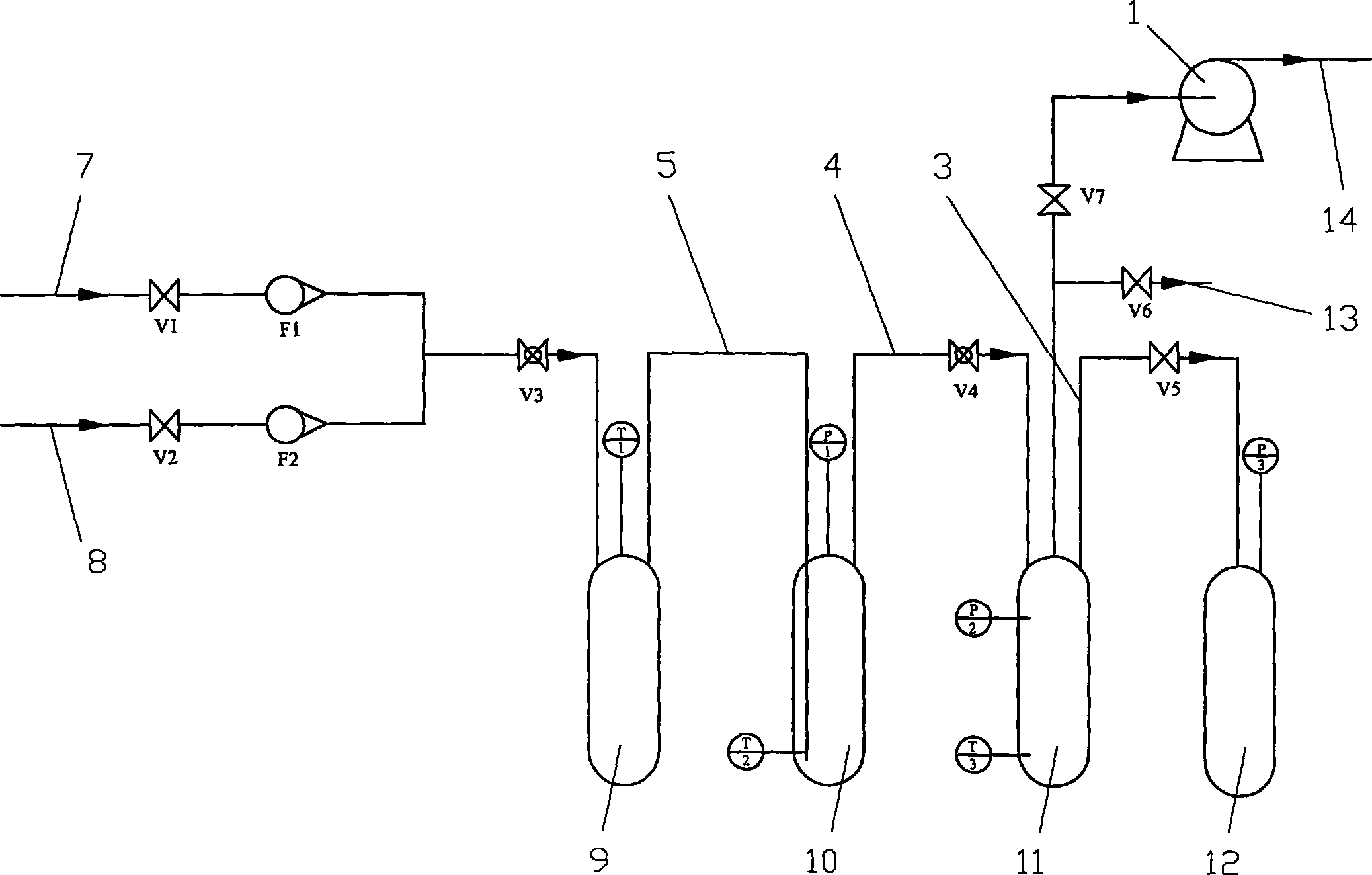

[0018] As shown in the accompanying drawings, the entire preparation system is cleaned up in advance with a vacuum pump 1 by vacuuming. The purity of raw fluorine gas is 99%, of which H 2 The O content is 1 ppmv or less, and the HF impurity content is 10 ppmv. Fluorine gas and high-purity nitrogen enter the cracker 9 through pipelines 7 and 8 respectively at a weight ratio of 1:4 at a rate of 1 L / min for preheating. The preheating temperature is 80±5°C, the operating pressure is 0.2MPa, the gas residence time is 5min, and then enters the reactor 10 through the pipeline 5. The cracker 9 has a diameter of 100 mm, a length of 500 mm, and a coil pipe inside. The cracker 9 is made of Monel material. The reactor 10 has a diameter of 300 mm and a height of 600 mm, and is made of Monel material. 10kg of tungsten powder with a purity of 99.95% and a size of 80 mesh is added to the inside. The temperature of the reactor 10 is 150±10° C., the operating pressure is 0.2 MPa, and the re...

Embodiment 2

[0021] The whole preparation system is cleaned up by vacuuming in advance, as shown in the accompanying drawing. The raw material fluorine gas is replaced with nitrogen trifluoride gas. Raw material NF 3 The purity of the gas is 99.9%, and the contents of HF and water are both below 1ppmv. Raw material NF 3 Gas and high-purity nitrogen are passed into the cracker at a rate of 1 L / min at a ratio of 1:1. The operating temperature of the cracker is controlled at 450±10°C, the operating pressure is controlled at 0.2MPa, and the cracking time of the raw gas in the cracker is 5 minutes before entering the reactor. 10kg of tungsten powder with a purity of 99.95% and a size of 80 mesh was added to the reactor. The temperature of the reactor is 150±10°C, the operating pressure is 0.2MPa, and the reaction time between cracked gas and tungsten powder is 5min. synthetic WF 6 The gas is then liquefied and collected with a cryogenic collector. The temperature of the cryogenic collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com