Silica-gel foaming-gel heat-insulation pipe and preparing method

A technology of silica gel foaming and thermal insulation pipes, which is applied in the chemical industry, can solve the problems of heat insulation effect, poor tensile strength and aging resistance, narrow product temperature range, and insufficient softness of products, and achieve tensile strength and aging resistance Excellent, wide temperature range, easy cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

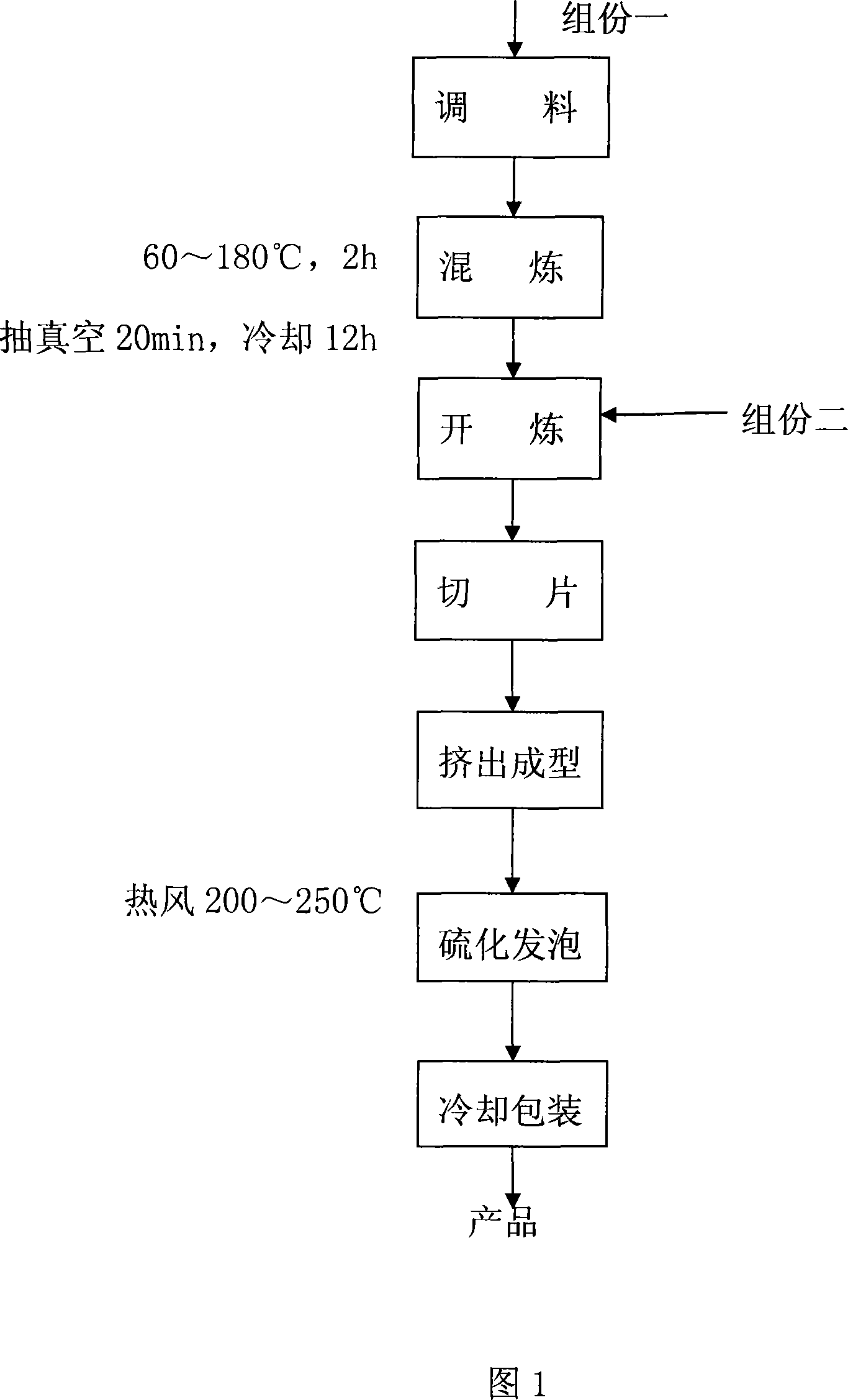

[0042] The silica gel foam insulation pipe of the present invention and its preparation method will be further described in detail below in conjunction with the accompanying drawings.

[0043] The composition and parts by weight of the silica gel foam insulation pipe of the present invention are as follows:

[0044] (1) Component 1, the dosage is 75.04~107.8 parts, the composition of this component 1 is:

[0045] (a) 45-55 parts of methyl vinyl silicone rubber;

[0046] (b) 20 to 30 parts of white carbon black;

[0047] (c) 2 to 5 parts of hydroxy silicone oil;

[0048] (d) 2 to 6 parts of methyl silicone oil;

[0049] (e) 5-8 parts of filler;

[0050] (f) 1 to 3 parts of polyvinyl silicone oil;

[0051] (g) 0.04~0.08 parts of colorant;

[0052] (2) Component 2, the dosage is 5.1 to 12.2 parts, the composition of the component 2 is:

[0053] (a) 4 to 10 parts of foaming agent;

[0054] (b) 1 to 2 parts of bridging agent;

[0055] (c) 0.1 to 0.2 parts of stabilizer.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com