Coal-water slurry combustion method and its combustion equipment

A combustion method and combustion equipment technology, applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of incomplete combustion, waste of coal water slurry resources, short combustion time, etc., to achieve complete combustion, It is convenient for automatic control and fuel consumption, and the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment and accompanying drawing, the present invention is further described in detail.

[0031] This example is a non-limiting example of the present invention.

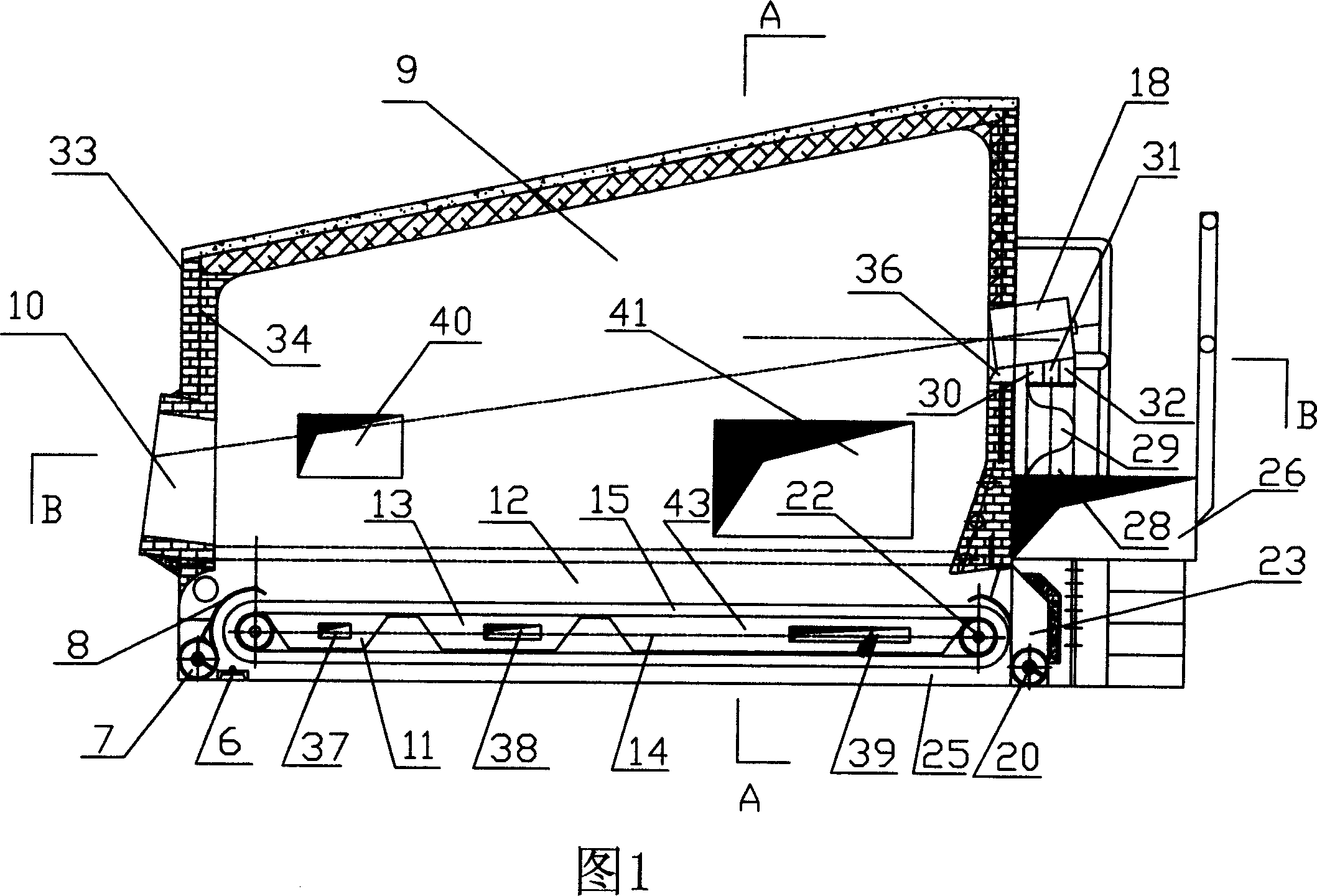

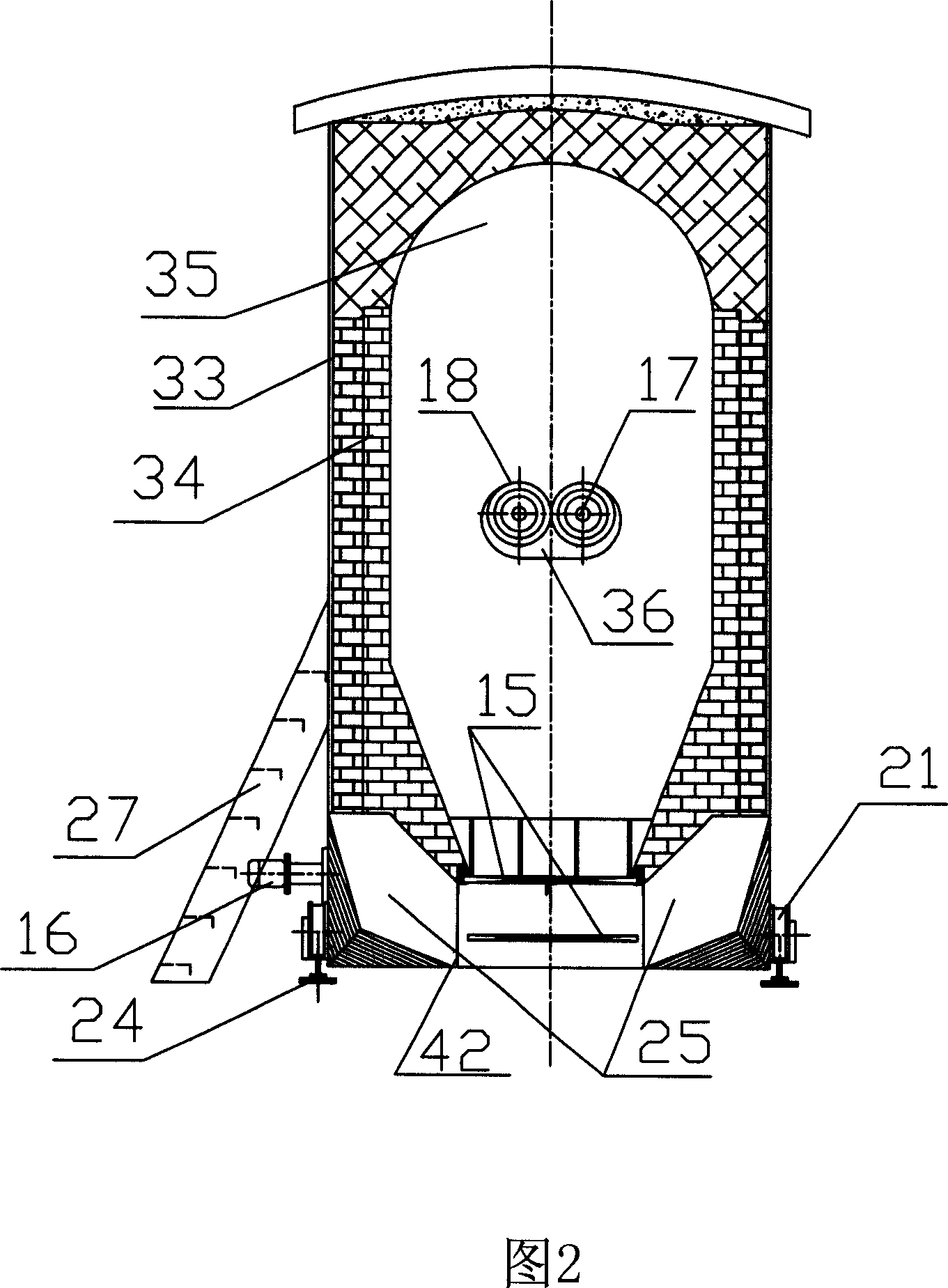

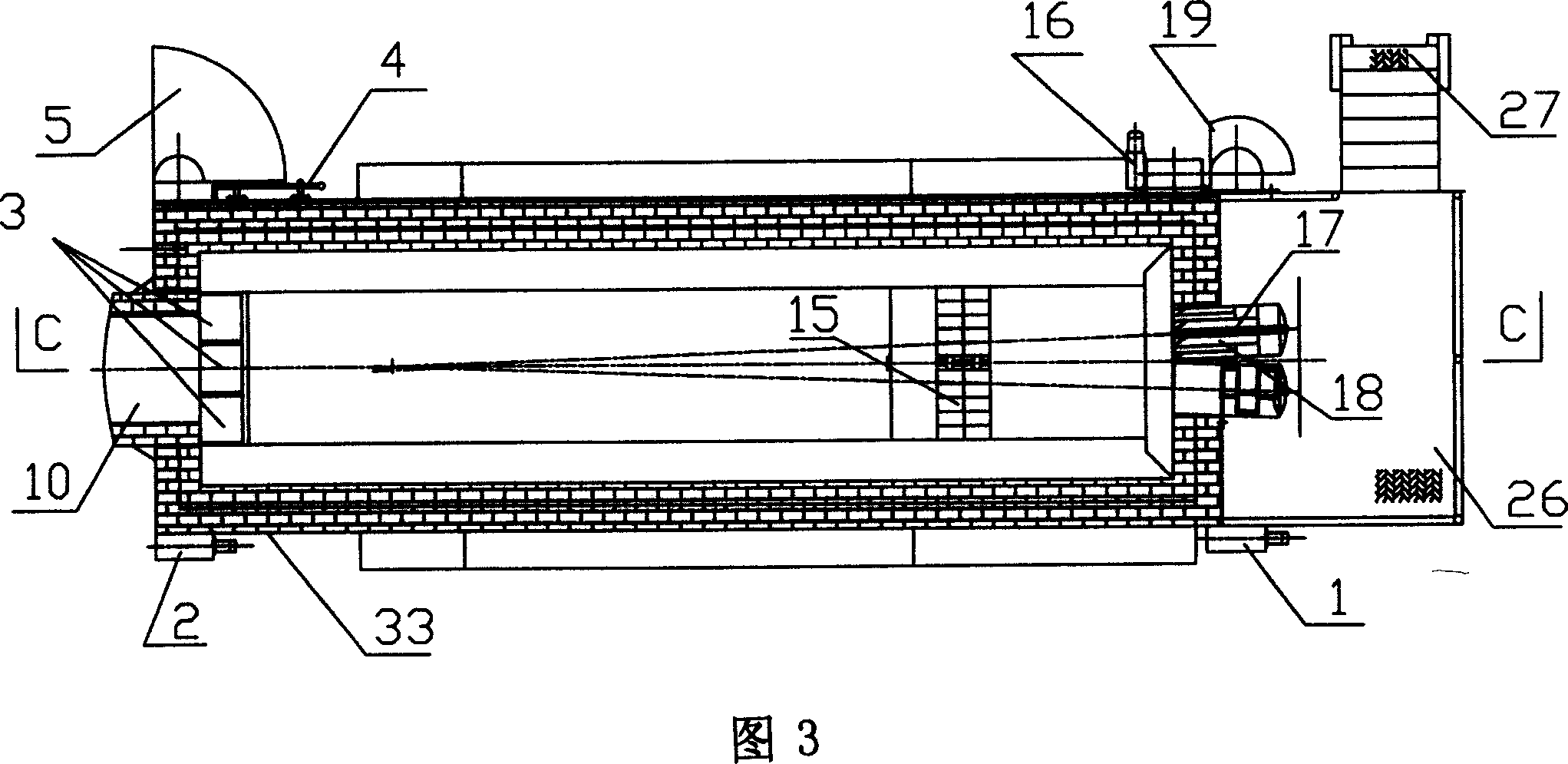

[0032] As shown in Figures 1, 2, and 3, the device of the present invention mainly includes a furnace 33, a coal-water slurry injection burner 17, an ignition burner 36 and a dust collector (not shown) on the flue. In the furnace 33 is a combustion chamber, and the fuel injection end of the furnace 33 has a platform-type main air duct 26 supplied by a blower (not shown in the figure), a total regulating air valve 28, a flexible air pipe 29, an air regulator 18, The air duct 25 and three dampers connected with the flexible duct 29 are the primary damper 32 , the secondary damper 31 and the tertiary damper 30 .

[0033] The platform-type main air duct 26 is above the sub-air duct 25 at the front end of the furnace 33 , and is below the flexible air duct 29 , and the flexible air du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com