Ph@PVA superconducting nano coaxial cable and its preparing method

A coaxial cable and nano-technology, applied in the field of Pb@PVA superconducting nano-coaxial cable and its preparation, can solve the problems of inability to use superconducting nano-electronic devices, unsuitable superconducting nano-coaxial cables, structural characteristics, and chemical properties Differences and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

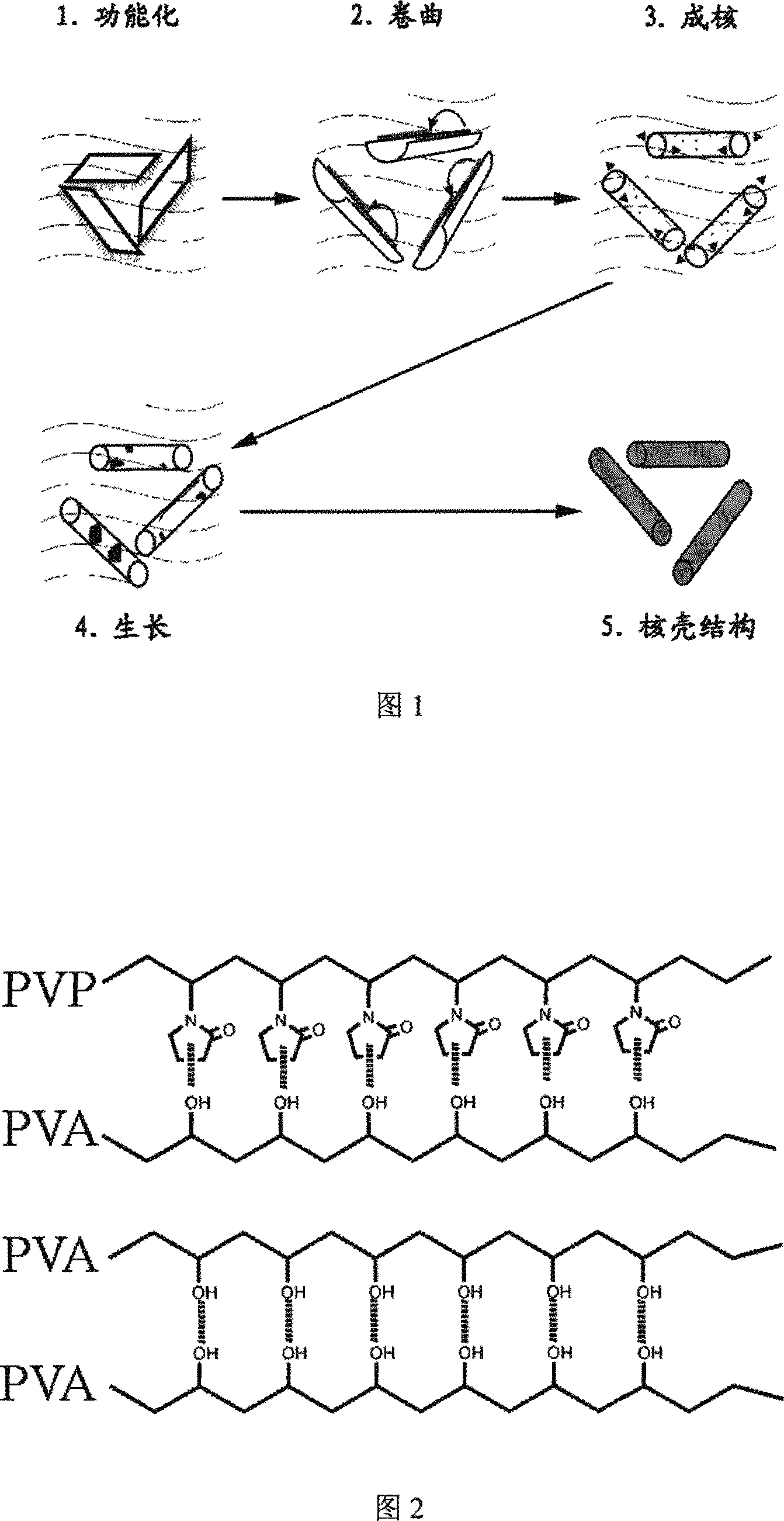

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Pb@PVA superconducting nano-coaxial cable was prepared under the conditions of 185° C. and reactant mass ratio of 5:5:1.

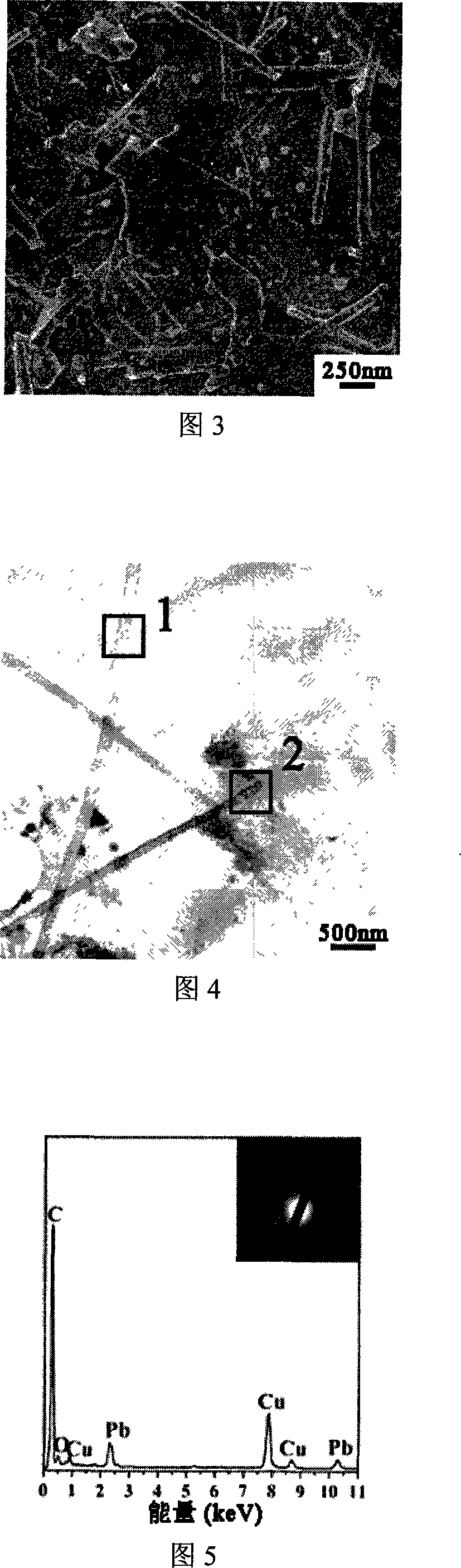

[0032] Configure the reactants according to the mass ratio of 5:5:1: weigh 0.21g of Pb(CH 3 COO) 2 ·3H 2 O, 0.21g PVP, what used here is the PVP that molecular weight is 40000; Weigh 0.042g PVA, what used here is the PVA that molecular weight is 1750; Dissolve in 14ml ethylene glycol, make solution and pour it into autoclave and seal the autoclave, usually with an anti-corrosion lining, what is used here is an autoclave with a volume of 20ml and lined with polytetrafluoroethylene; the autoclave is placed in a crucible resistance furnace, Raise the temperature at a slow heating rate. Normally, the heating rate should be controlled at 1-2.5°C / min. In this example, 1°C / min is used; after the temperature rises to 180°C, it is kept for 12 hours; after it is naturally cooled to room temperature The product solution was taken out, the product...

Embodiment 2

[0042] Example 2: Pb@PVA superconducting nano-coaxial cable was prepared under the conditions of 190° C. and reactant mass ratio of 4.5:5.5:1.

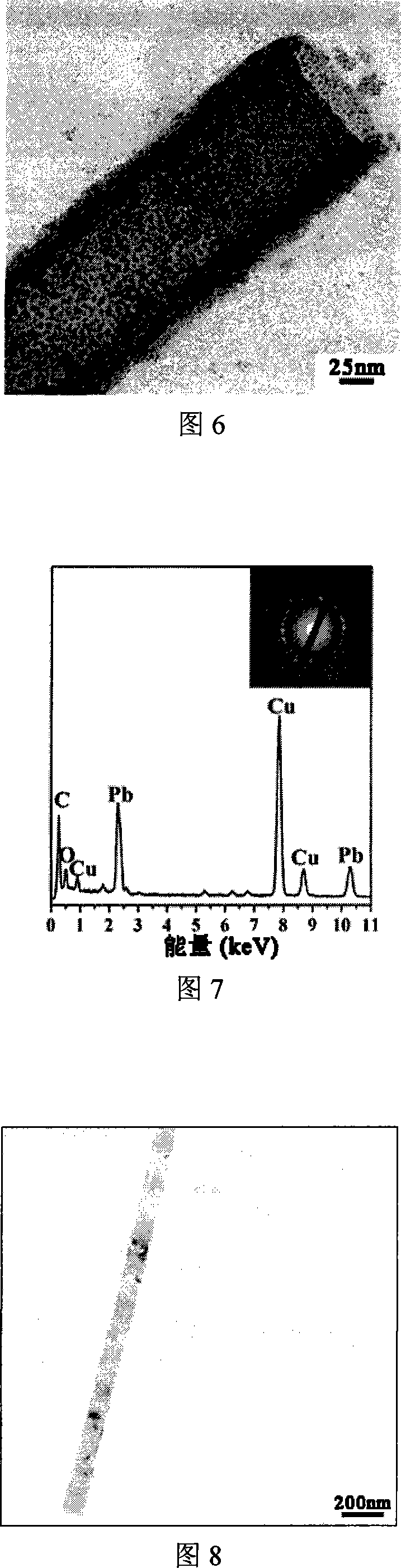

[0043] Weigh 0.21g of Pb(CH 3 COO) 2 ·3H 2 O, 0.26g of PVP with a molecular weight of 40,000; weigh 0.046g of PVA with a molecular weight of 1750; dissolve it in 12ml of ethylene glycol, and pour it into a 20ml autoclave with a Teflon liner After sealing, place the autoclave in a crucible resistance furnace, raise the temperature to 190°C at a rate of 2°C / min, and then keep it warm for 24 hours; after it is naturally cooled to room temperature, take out the product solution, centrifuge to separate the product, and use Sample 6 was obtained after washing with water and ethanol three times and vacuum drying.

[0044] The samples were characterized by JElectronics JSM-6700F field emission scanning electron microscope, Hitachi H-800 transmission electron microscope, and Philips X’Pert X-ray diffractometer in the Netherlands.

[0045] ...

Embodiment 3

[0048] Example 3: Preparation of Pb@PVA superconducting nano-coaxial cables at 200° C. and reactant mass ratio of 5.5:4.5:1.

[0049] Configure the reactants according to the mass ratio of 5.5:4.5:1: weigh 0.21g Pb(CH 3 COO) 2 ·3H 2 O, 0.17g molecular weight is the PVP of 40000; 0.038 g molecular weight is the PVA of 1750; It is dissolved in 14ml ethylene glycol, and it is poured into after making solution and volume is that 20ml has the autoclave of polytetrafluoroethylene liner, After sealing, place the autoclave in a crucible resistance furnace, heat it up to 200°C at a rate of 2°C / min, and keep it warm for 12 hours; after it is naturally cooled to room temperature, take out the product solution, centrifuge to separate the product, and wash it with absolute ethanol Sample 7 was obtained after washing three times and vacuum drying.

[0050] The samples were characterized by JElectronics JSM-6700F field emission scanning electron microscope, Hitachi H-800 transmission elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com