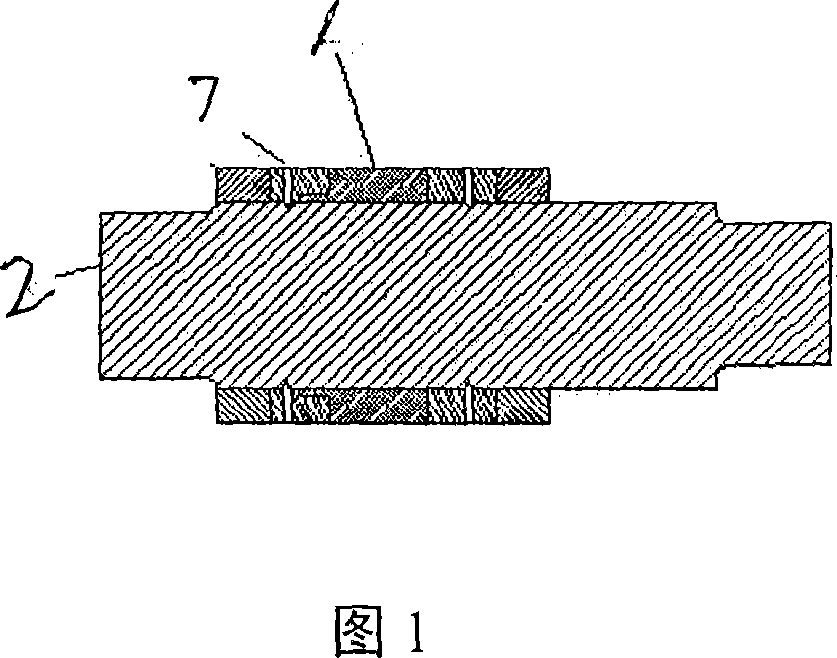

Composite roller of high-performance binded hard alloy

A technology of cemented carbide and composite rolls, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of limited bonding strength rolling torque, low ability to transmit rolling torque, limited bonding area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

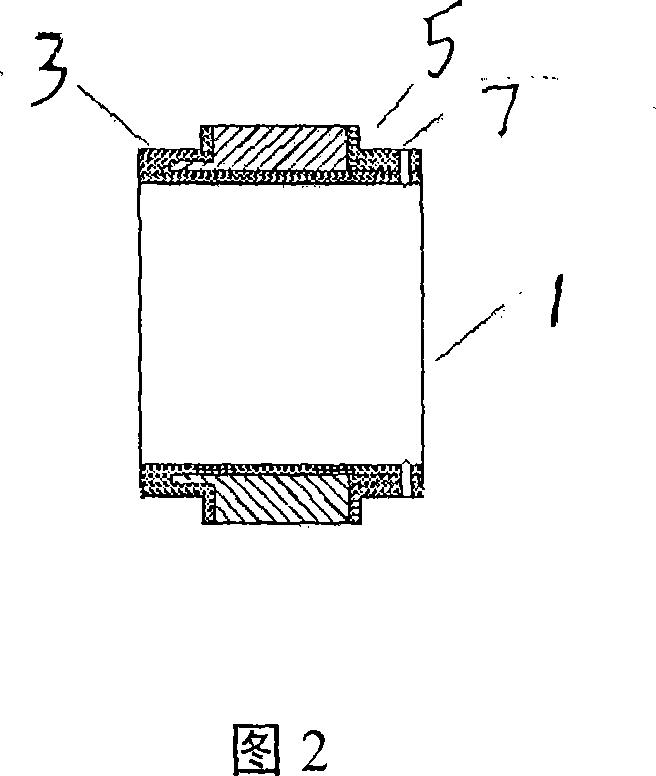

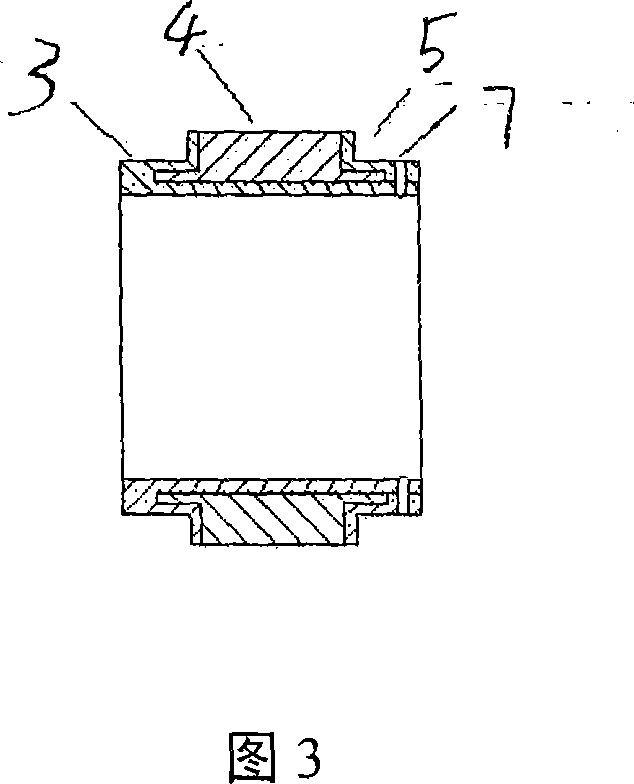

example 1

[0022] Example 1: Assume that a strip mill requires transmission torque M = 120KN.m, working face width h = 150mm, roll outer diameter D = 320mm, inner diameter d = 250mm, safety factor = 10, the calculation shows that for hard alloy without steps Composite roll rings or composite rolls require a shear strength of 81.5 MPa for the composite layer. Obviously, chemical bonding and compounding cannot achieve this strength. However, if the composite roll ring or composite roll with auxiliary steps is used, as long as a bonded step with length a=75mm and u=10mm is added to the cemented carbide roll ring, the shear strength of the cemented layer can reach 41MPa. Obviously, this is easy. achieved at an increased weight cost of only 6%.

example 2

[0023] Example 2: Assume that a pipe rolling mill requires transmission torque M = 120KN.m, working face width h = 120mm, roll outer diameter D = 320mm, inner diameter d = 260mm, safety factor = 10, the calculation shows that for no step cemented carbide composite For roll rings or composite rolls, the shear strength of the composite layer is required to be 102MPa. Obviously, chemical bonding methods cannot achieve this strength. However, if the composite roll ring or composite roll with auxiliary steps is used, as long as a bonded step with length a=100mm and u=10mm is added to the cemented carbide roll ring, the shear strength of the cemented layer can reach 34MPa. Obviously, this is easy achieved at an increased weight cost of only 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com