Method for preparation of alloy extrudate

A technology of extruded profiles and alloys, which is applied in the field of non-ferrous metal preparation and processing, can solve the problems of unsatisfactory requirements for continuous profiles, high equipment requirements, and large material loss, and achieve saving raw material consumption, high mechanical properties, and reduced tonnage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

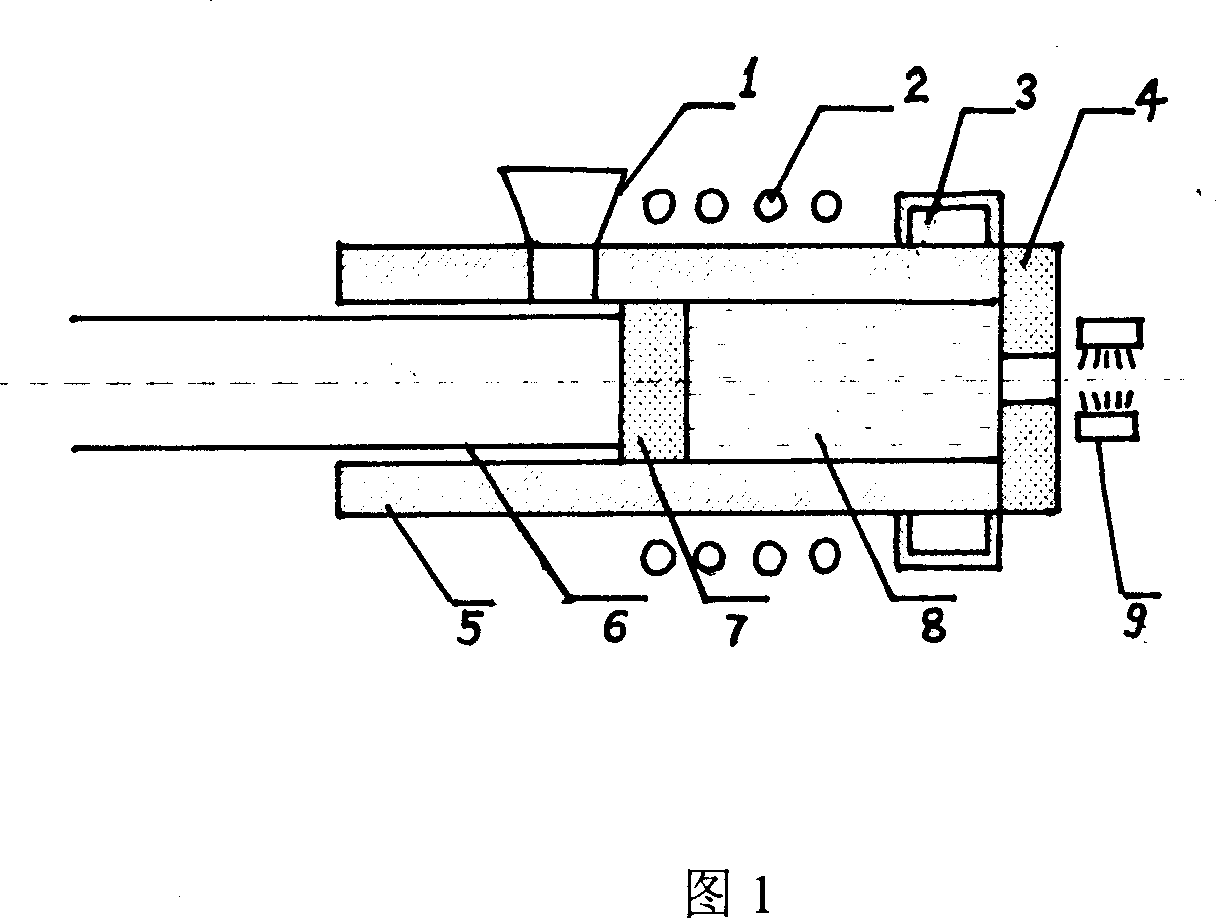

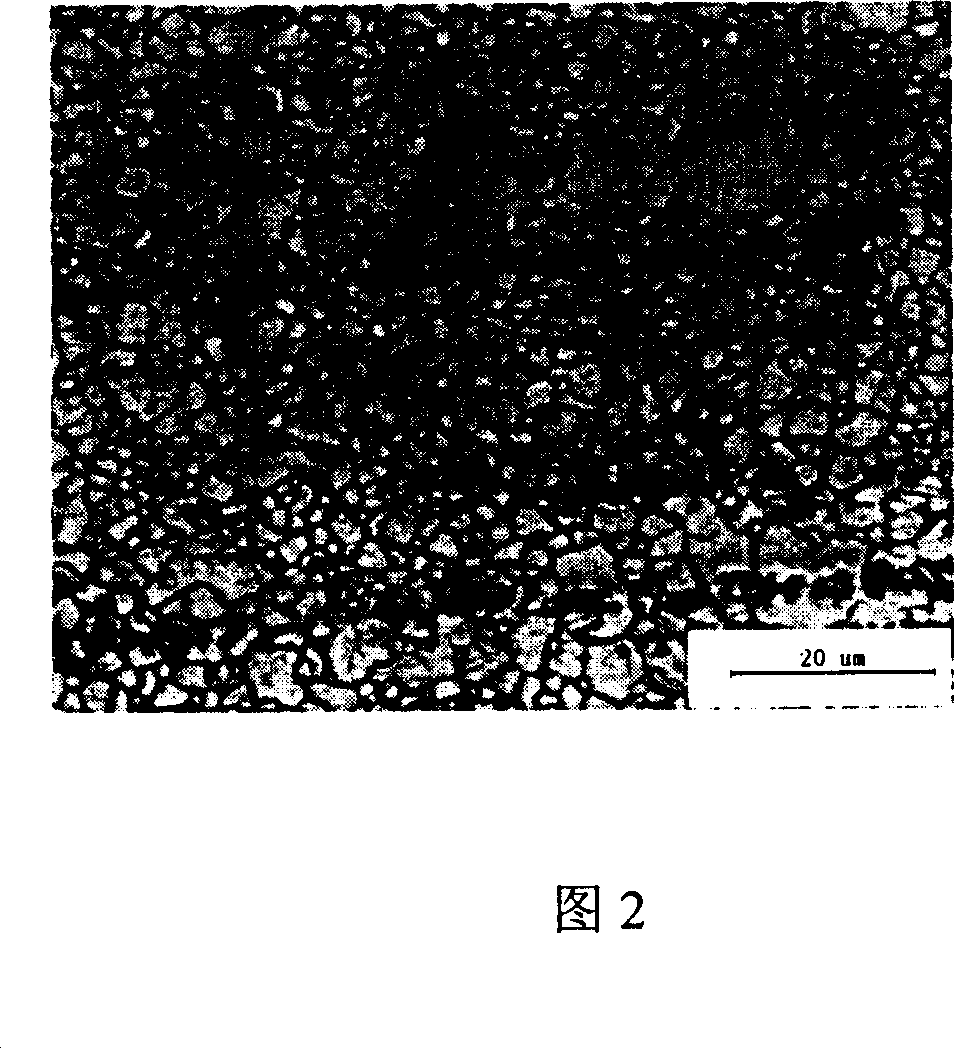

[0024] Prepare magnesium alloy AZ31B bar with a diameter of φ20mm. First, preheat the extrusion barrel sprue 1, the extrusion barrel 5, and the extrusion pad 7 to 650°C, and the extrusion die 4 to 400°C. The cooling jacket 3 at the front end of the extrusion barrel is controlled at 60°C by circulating cooling water. . After the AZ31B alloy is melted, a semi-solid and semi-liquid slurry is made by mechanical stirring, and then injected into a φ95mm extrusion cylinder at 628°C with an injection volume of about 3kg. The extrusion rod is squeezed forward, the slurry gradually fills the extrusion barrel and solidifies at the front end of the extrusion barrel. After being extruded from the extrusion die 4, it is cooled by the secondary cooling system 9 at the exit of the extrusion die 4 to obtain the Bars with specifications required. The bar has a yield strength of 280MPa, a tensile strength of 320MPa, and an elongation of 13.5%. The microstructure of the bar is shown in Figure 2.

Embodiment 2

[0026] Prepare magnesium alloy AZ31B pipe, the outer diameter of the pipe is φ30mm, and the inner diameter is φ22mm. First, preheat the pouring port, the extrusion barrel, the extrusion pad, and the perforation needle to 600°C, the extrusion die to 300°C, and the cooling jacket 3 at the front end of the extrusion barrel is controlled at 20°C by circulating cooling water. After the AZ31B alloy is melted, a semi-solid and semi-liquid slurry is made by mechanical stirring, and then injected into a φ95mm extrusion cylinder at 628°C with an injection volume of about 2.5kg. The extrusion rod and the perforated needle are extruded forward, and the slurry gradually fills the extrusion cylinder and solidifies at the front end of the extrusion cylinder. After being extruded from the extrusion die, it is cooled twice at the exit of the extrusion die to obtain the required specifications Pipe. The yield strength of the pipe is 220MPa, the tensile strength is 300MPa, and the elongation is 12%....

Embodiment 3

[0028] Prepare magnesium alloy AZ3 1B continuous sheet. The thickness of the plate is 5mm and the width is 100mm. First, preheat the pouring port, the extrusion barrel, and the extrusion pad to 600°C, the extrusion die to 350°C, and the cooling jacket 3 at the front end of the extrusion barrel is controlled at 70°C by circulating cooling water. After the AZ31B alloy is melted, a semi-solid and semi-liquid slurry is made by mechanical stirring, and then injected into a φ95mm extrusion cylinder at 628°C. The first injection volume is about 3kg. The extrusion rod is squeezed forward, the slurry gradually fills the extrusion barrel and solidifies at the front end of the extrusion barrel, and is extruded in the extrusion die. The extruded part is cooled at the exit of the extrusion die to obtain the required specifications. After extruding about 1kg, the squeeze rod drives the squeeze pad back to the left of the pouring port, and quickly pours about 1kg of the prepared semi-solid and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com