Eiderdown silk down-proof composite processing technology

A composite processing and down silk technology, applied in the field of down processing, can solve the problems of down removal, difficult application and high cost, and achieve the effects of simple production process, improved production efficiency, and convenient production and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

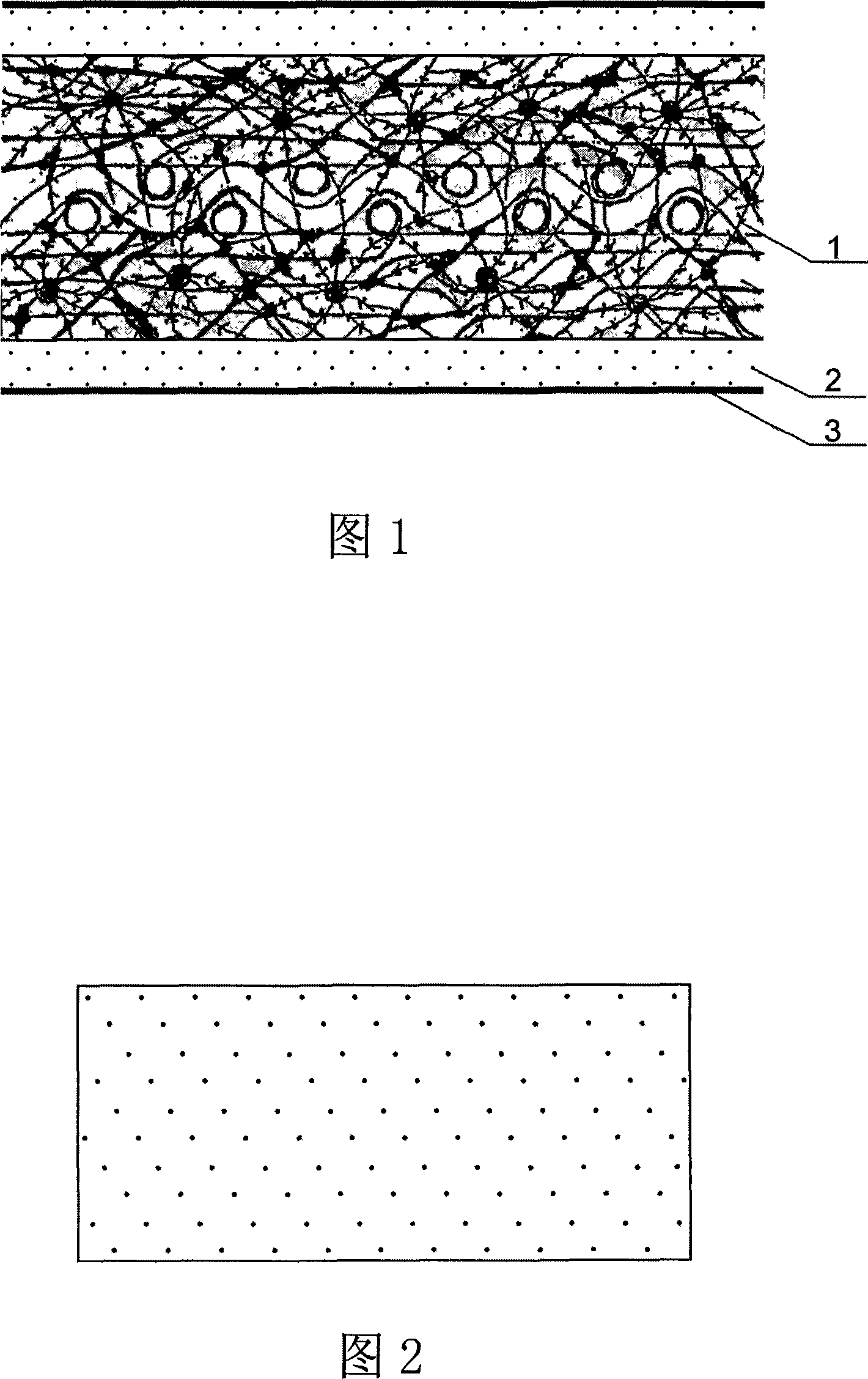

[0019] As shown in Figures 1 to 2: Feather down puffy tire 1 is composed of feather down fiber, three-dimensional crimped hollow, polyester staple fiber, low melting point fiber and textile fiber. It is made of acrylic monomer and polymerized into high The adhesive 2 made of molecular resin is composed of polyester and urethane-containing environment-friendly breathable film 3, which is formed as a whole through composite shaping process.

[0020] The structure of the feather and down bulky tire is an adhesive fiber network structure, which is a large number of feather and down monofilaments interlaced and bonded by adhesives. Since the bonding process must maintain the bulkiness of the bulky tire, its bonding It is limited, so there will be phenomena such as running wire, rolling hair, and flying hair. After countless experiments, it was found that although polyester and urethane-containing films are breathable, in the lamination process, if the adhesive is applied by ordinar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com