Middle-low temperature pseudo-binary electrothermal alloy and preparation process

A pseudo-binary, alloy technology, applied in the field of key components and materials, to achieve the effect of simple process, low cost and high thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

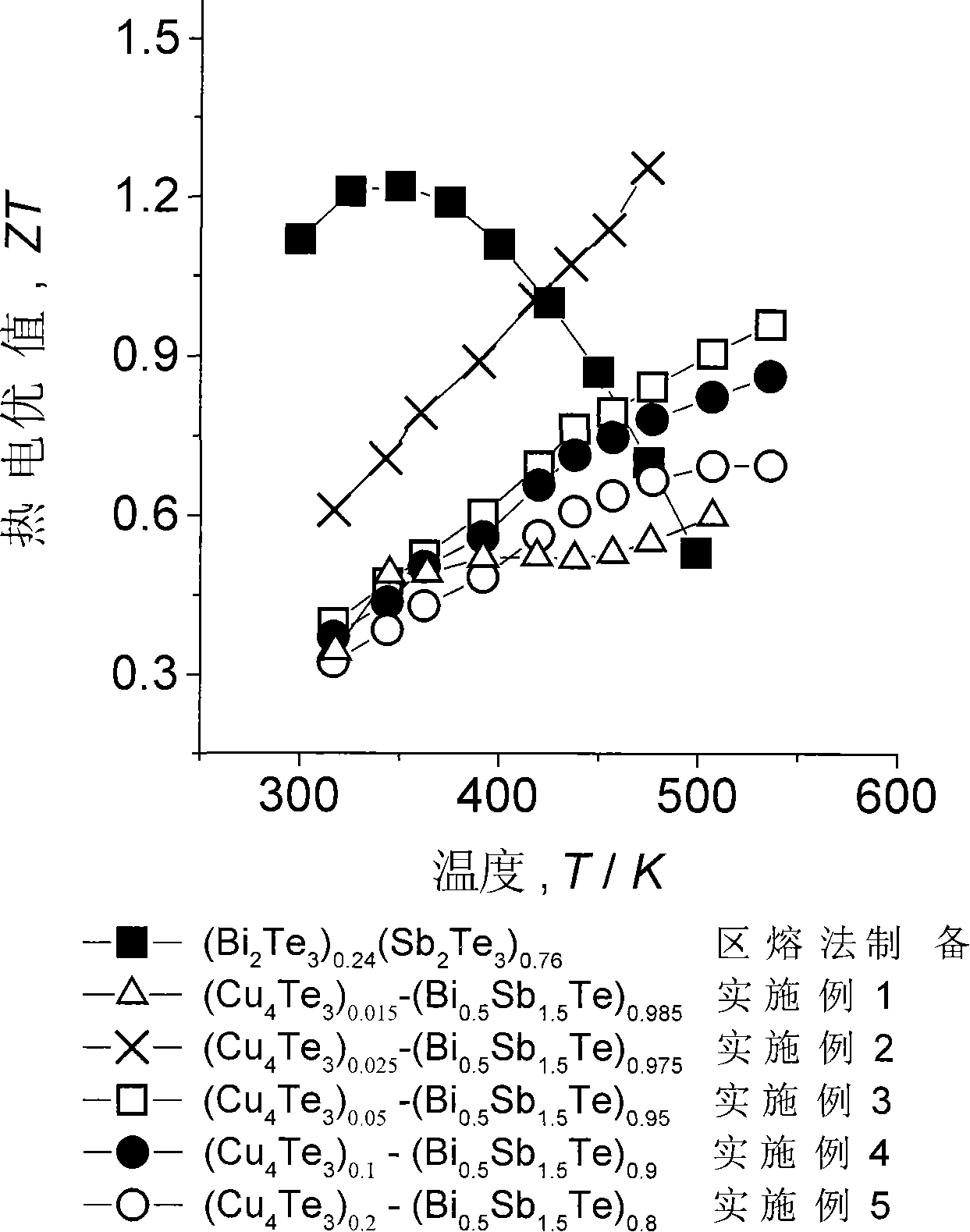

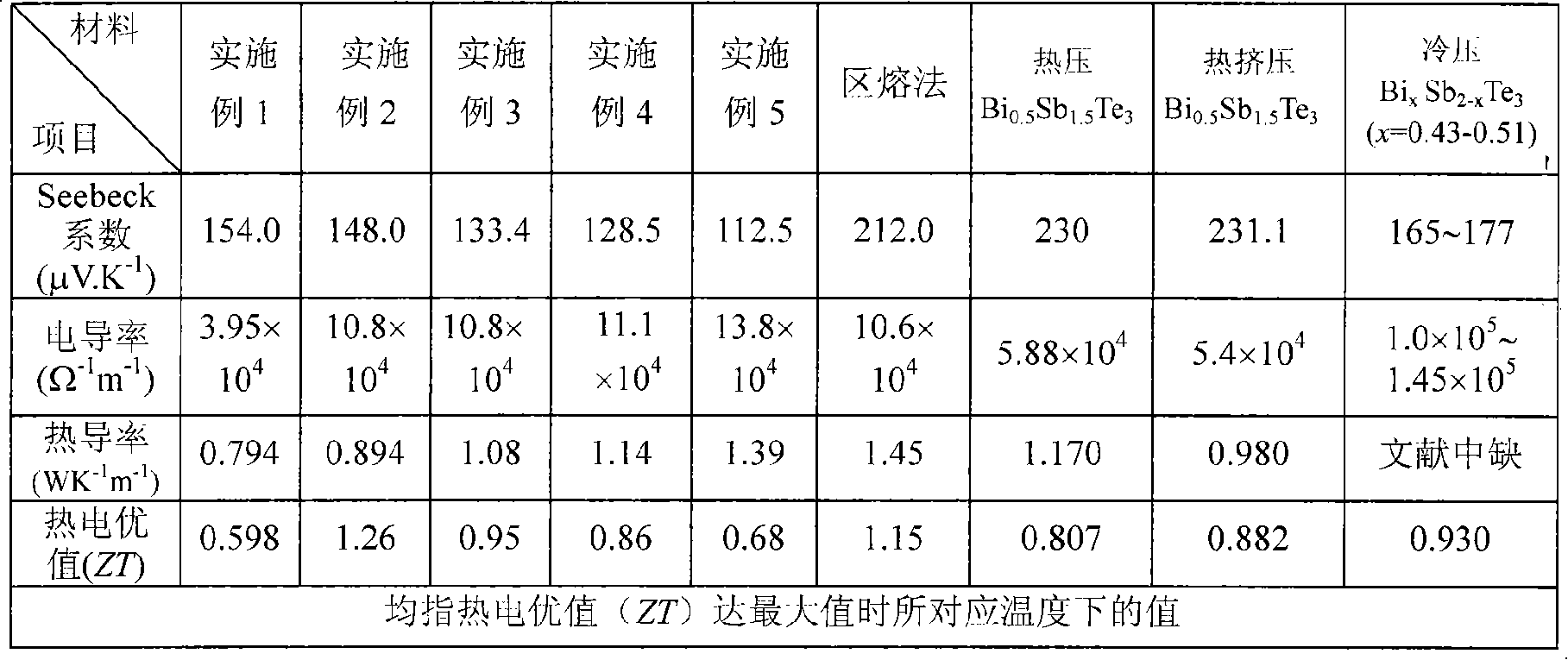

Embodiment 1

[0020] In the pseudo binary alloy Bi 0.5 Sb 1.5 Te 3 Cu with a mole fraction of 0.015 was used in 4 Te 3 Substitute equimolar fraction of Bi 0.5 Sb 1.5 Te 3 . First according to the chemical formula Cu 4 Te 3 and Bi 0.5 Sb 1.5 Te 3 Cu, Bi, Sb and Te four elements with a purity greater than 99.999wt.% were weighed and placed in vacuum quartz tubes respectively. Cu 4 Te 3 The melting temperature of Bi is 1000-1100°C. 0.5 Sb 1.5 Te 3 The temperature is 700-800°C, the smelting and synthesis time is 10 hours each, and it is crushed after quenching and cooling. Then according to the chemical formula (Cu 4 Te 3 ) 0.015 -(Bi 0.5 Sb 1.5 Te 3 ) 0.985 Weigh the corresponding amount of Cu 4 Te 3 and Bi 0.5 Sb 1.5 Te 3 , placed in a vacuum quartz tube again, melted and synthesized at a temperature of 1000-1100 ° C for 10 hours. Shake the tube every 1 hour during the melt to ensure a uniform reaction. After 10 hours, it was quenched in water to obtain a block ...

Embodiment 2

[0022] In the pseudo binary alloy Bi 0.5 Sb 1.5 Te 3 Cu with a mole fraction of 0.025 was used in 4 Te 3 Substitute equimolar fraction of Bi 0.5 Sb 1.5 Te 3 . First according to the chemical formula Cu 4 Te 3 and Bi 0.5 Sb 1.5 Te 3 Cu, Bi, Sb and Te four elements with a purity greater than 99.999wt.% were weighed and placed in vacuum quartz tubes respectively. Cu 4 Te 3 The melting temperature of Bi is 1000-1100°C. 0.5 Sb 1.5 Te 3 The temperature is 700-800°C, the smelting and synthesis time is 10 hours each, and it is crushed after quenching and cooling. Then according to the chemical formula (Cu 4 Te 3 ) 0.025 -(Bi 0.5 Sb 1.5 Te 3 ) 0.975 Weigh the corresponding amount of Cu 4 Te 3 and Bi 0.5 Sb 1.5 Te 3 , placed in a vacuum quartz tube again, melted and synthesized at a temperature of 1000-1100 ° C for 10 hours. Shake the tube every 1 hour during the melt to ensure a uniform reaction. After 10 hours, it was quenched in water to obtain a block ...

Embodiment 3

[0024] In the pseudo binary alloy Bi 0.5 Sb 1.5 Te 3 Cu with a mole fraction of 0.05 was used in 4 Te 3 Substitute equimolar fraction of Bi 0.5 Sb 1.5 Te 3 . First according to the chemical formula Cu 4 Te 3 and Bi 0.5 Sb 1.5 Te 3 Cu, Bi, Sb and Te four elements with a purity greater than 99.999wt.% were weighed and placed in vacuum quartz tubes respectively. Cu 4 Te 3 The melting temperature of Bi is 1000-1100°C. 0.5 Sb 1.5 Te 3 The temperature is 700-800°C, the smelting and synthesis time is 10 hours each, and it is crushed after quenching and cooling. Then according to the chemical formula (Cu 4 Te 3 ) 0.05 (Bi 0.5 Sb 1.5 Te 3 ) 0.95 Weigh the corresponding amount of Cu 4 Te 3 and Bi 0.5 Sb 1.5 Te 3 , placed in a vacuum quartz tube again, melted and synthesized at a temperature of 1000-1100 ° C for 10 hours. Shake the tube every 1 hour during the melt to ensure a uniform reaction. After 10 hours, it was quenched in water to obtain a block pseu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com