Deodorization method for town refuse biology re-fermentation

A technology for municipal waste and re-fermentation, which is applied in biochemical equipment and methods, solid waste removal, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

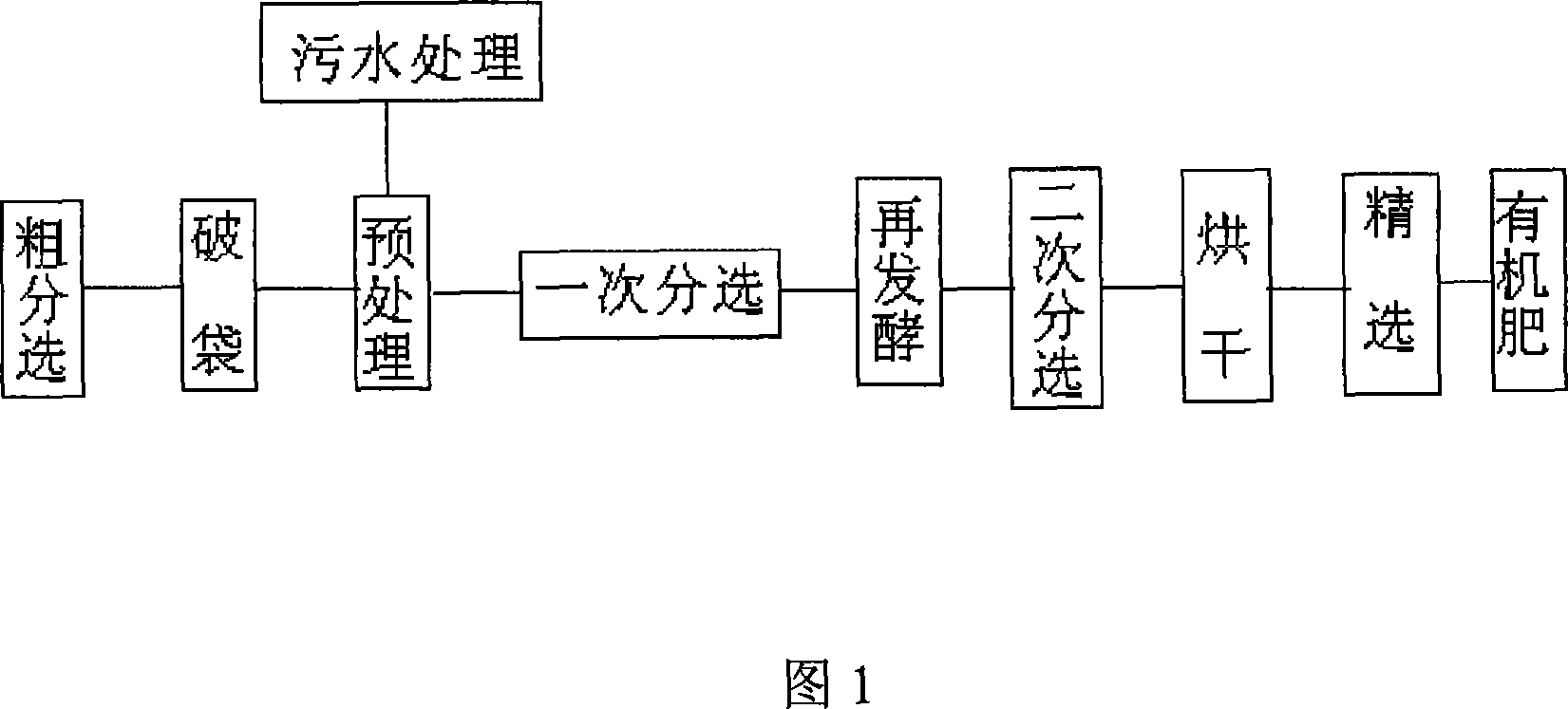

Image

Examples

Embodiment 1

[0020] Raw garbage first undergoes a rough sorting process, separating the bamboo and wood packaging boxes and rubber tires, and breaking the large pieces;

[0021] The coarsely sorted garbage is broken into bags, and the broken bags are mixed and weighed. During the mixing process, mixed bacteria are added. After the bacteria are expanded and cultivated, they are mixed according to the following volume ratio: Alcalibacter xylosoxidans Alcaligenes xylosoxidans subsp CGMCC 1.768: Bacillus amyloliquefaciens CGMCC 1.1177: Deinococcus radiodurans CGMCC 1.633: Debaryomyces hansenii CGMCC 2.183l: Issatchenkia scutulata CGMCC 2.1592, Aleuisma keratinophilum CGMCC 3.3544: Nocardia brasiliensis CGMCC 4.1128=10:5:10:1:5:10. (Contains 2×10 per milliliter of liquid 7 active cells or more).

[0022] Dilute the mixed strains according to the volume ratio of 1:50, add the diluted mixed strains according to 0.5% (V / W) of the weight of the garbage, ventilate and supply oxygen for fermentatio...

Embodiment 2

[0029] Raw garbage first undergoes a rough sorting process, separating the bamboo and wood packaging boxes and rubber tires, and breaking the large pieces;

[0030] The coarsely sorted garbage is broken into bags, and the broken bags are mixed and weighed. During the mixing process, mixed bacteria are added. After the bacteria are expanded and cultivated, they are mixed according to the following volume ratio: Alcalibacter xylosoxidans Alcaligenes xylosoxidans subsp CGMCC 1.768: Bacillus amyloliquefaciens CGMCC 1.1177: Deinococcus radiodurans CGMCC 1.633: Debaryomyces hansenii CGMCC 2.1831: Issatchenkia scutulata CGMCC 2.1592, Aleuisma keratinophilum CGMCC 3.3544: Nocardia brasiliensis CGMCC 4.1128=12:7:15:15:10:15. (Contains 2×10 per milliliter of liquid 7 active cells or more).

[0031] Dilute the mixed strains according to the volume ratio of 1:75, add the diluted mixed strains according to 2.5% (V / W) of the weight of the garbage, ventilate and supply oxygen for fermentat...

Embodiment 3

[0038] Raw garbage first undergoes a rough sorting process, separating the bamboo and wood packaging boxes and rubber tires, and breaking the large pieces;

[0039] The coarsely sorted garbage is broken into bags, and the broken bags are mixed and weighed. During the mixing process, mixed bacteria are added. After the bacteria are expanded and cultivated, they are mixed according to the following volume ratio: Alcalibacter xylosoxidans Alcaligenes xylosoxidans subsp CGMCC 1.768: Bacillus amyloliquefaciens CGMCC 1.1177: Deinococcus radiodurans CGMCC 1.633: Debaryomyces hansenii CGMCC 2.1831: Issatchenkia scutulata CGMCC 2.1592, Aleuisma keratinophilum CGMCC 3.3544: Nocardia brasiliensis CGMCC 4.1128=15:10:20:30:15:20. (Contains 2×10 per milliliter of liquid 7 active cells or more).

[0040] Dilute the mixed bacteria according to the volume ratio of 1:100, add the diluted mixed bacteria according to 5% (V / W) of the weight of the garbage, ventilate and supply oxygen for ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com