Diosmin producing process

A production method, the technology of diosmin, is applied in the direction of sugar derivatives and organic chemistry, which can solve the problems of long process route, complex reaction, and influence on reaction speed, and achieve simple process operation, high product purity, and reduced use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

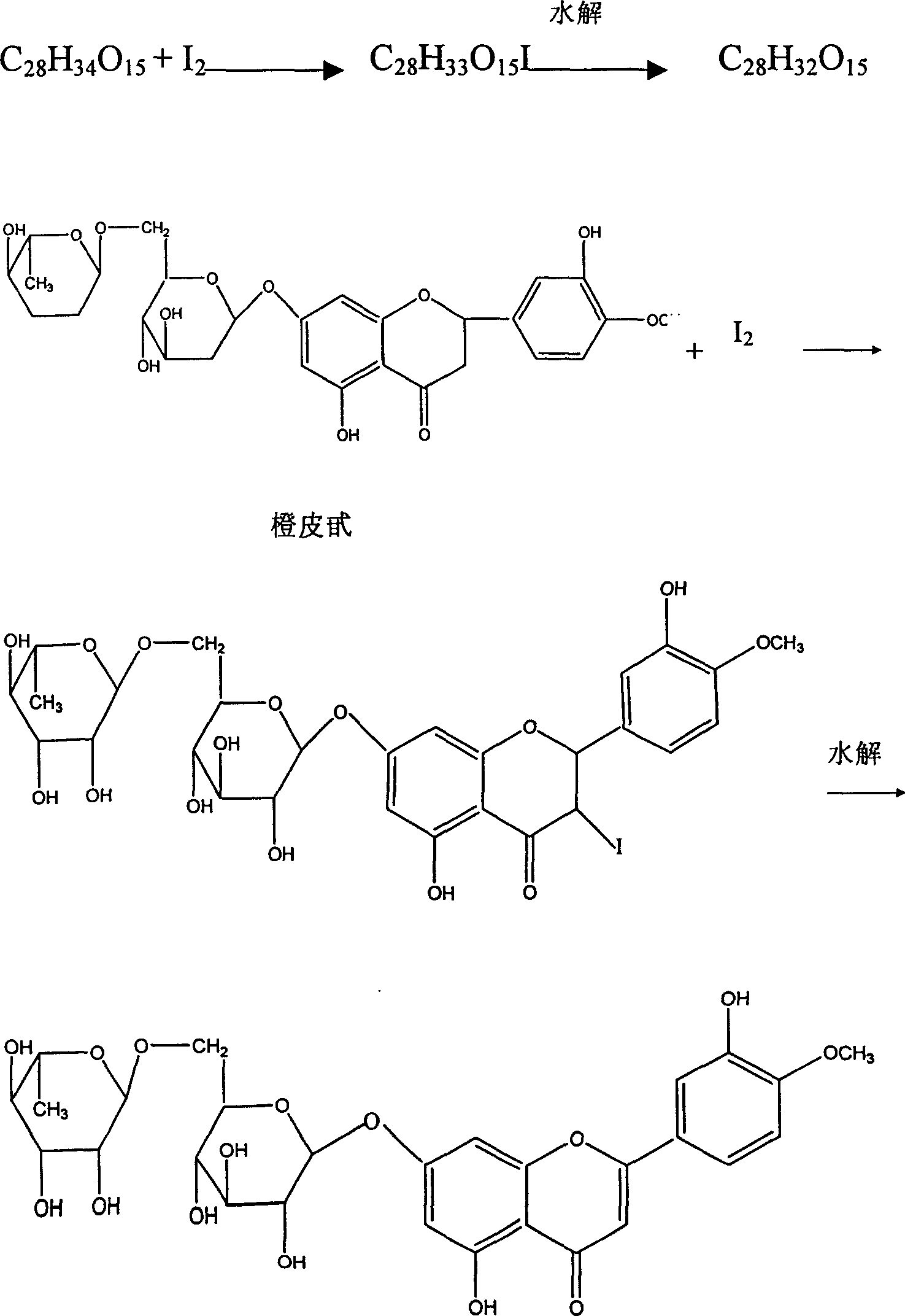

Image

Examples

Embodiment 1

[0019] The method of this embodiment 1 is 100 grams of hesperidin, add 200 milliliters of dimethylformamide, then evaporate to dryness under reduced pressure, remove the crystal water in the hesperidin like this, then add 500 milliliters of pyridine, 4 grams of iodine, heat to reflux React for 12 hours, concentrate to dryness under reduced pressure, then add 100 ml of 5% sodium hydroxide aqueous solution, stir at 30 degrees for 8 hours, filter, adjust pH to 4 with dilute hydrochloric acid, filter the obtained solid, wash with water until neutral , dried to obtain 90 grams of light yellow solid powder-diosmin, product melting point, iodine residue, solvent residue, related impurities and content all up to standard.

Embodiment 2

[0021] Method 2 of this embodiment is to add 100 milliliters of hesperidin to 100 milliliters of dimethylformamide, then distill to dryness under reduced pressure, thus removing the crystal water in hesperidin, then add 800 milliliters of pyridine and 5 grams of iodine, and heat to reflux React for 8 hours, concentrate to dryness under reduced pressure, then add 200 ml of 2.5% sodium hydroxide, stir at 80 degrees for 2 hours, filter, adjust pH to 4.5 with dilute hydrochloric acid, filter the obtained solid, wash with water until neutral, Dry to obtain 93 grams of light yellow solid powder-diosmin, the product melting point, iodine residue, solvent residue, related impurities and content are all up to standard.

Embodiment 3

[0023] Method 3 of this embodiment is 100 grams of hesperidin, add 300 milliliters of dimethylformamide, then evaporate to dryness under reduced pressure, remove the crystal water in the hesperidin like this, then add 300 milliliters of pyridine, 4.5 grams of iodine, heat to reflux React for 16 hours, concentrate to dryness under reduced pressure, then add 100 ml of 5% sodium hydroxide, stir at 50°C for 6 hours, filter, adjust pH to 4.5 with dilute hydrochloric acid, filter the obtained solid, wash with water until neutral, Dry to obtain 85 grams of light yellow solid powder-diosmin, the product melting point, iodine residue, solvent residue, related impurities and content are all up to standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com