Heat preservation putty for inner / outer walls of architecture

A technology of thermal insulation putty and interior and exterior walls, applied in the direction of filling slurry, etc., can solve the problems of cumbersome construction, high unit cost, secondary pollution, etc., and achieve the effects of easy construction, low thermal conductivity, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

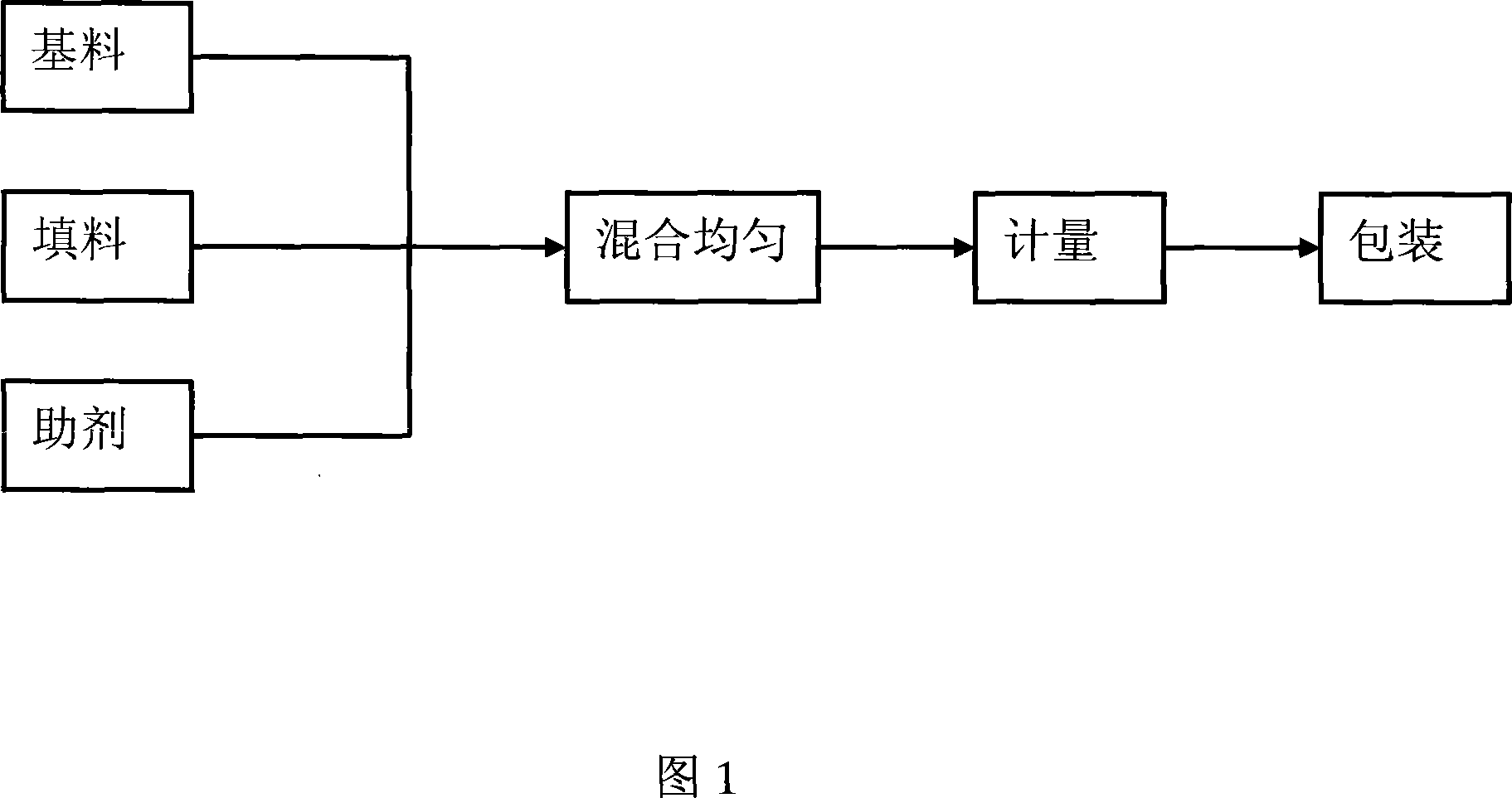

[0048] The preparation process of the invention is as follows: mixing the base material, the filler and the auxiliary agent according to a certain weight ratio, stirring evenly, and measuring and packaging. The construction method is: the base layer should meet the following requirements before construction: smooth, no oil, no powder, no hollowing, cracks, floating ash, no obvious unevenness, according to the ratio of putty and water as 1:0.4 and stir it into a paste After the paste is formed, scrape in batches, and the thickness is controlled between 2mm-3mm. After the first pass is dried, scrape in batches for the second time. Use as much as you want each time. The prepared putty should be used up within 2-3 hours.

[0049] The performance index of the present invention is as follows: according to (putty for building exterior wall) (JG / T157-2004) national standard putty performance is detected, and the results are shown in Table 4 (putty detection result for building exterior...

Embodiment 1

[0054] The optimal ratio of the raw material components of the interior and exterior wall thermal insulation putty provided by the present invention is as follows:

[0055] Redispersible latex powder 5

[0056] Portland cement 6

[0057] Cenospheres 30

[0058] Expanded Perlite Powder 30

[0059] Ash calcium powder 10

[0060] Talc 20

[0061] Hydroxypropyl methylcellulose 0.3

[0062] Polypropylene fiber 0.1

[0063] Silica powder 5.

Embodiment 2

[0065] The proportioning of the raw material components of the interior and exterior wall thermal insulation putty provided by the present invention is as follows through experiments:

[0066] Redispersible latex powder 4

[0067]Portland cement 7

[0068] Cenospheres 25

[0069] Expanded Perlite Powder 25

[0070] Ash calcium powder 15

[0071] Talc 20

[0072] Hydroxypropyl methylcellulose 0.2

[0073] Polypropylene fiber 0.2

[0074] Silica powder 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com