Method for cultivating methane-oxidizing bacteria

A methane-oxidizing bacteria and culture method technology, applied in a fast, high-density culture field, can solve problems such as complex process, explosion, increased power consumption, etc., achieve broad application prospects, simple culture method, increase growth rate and cell effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

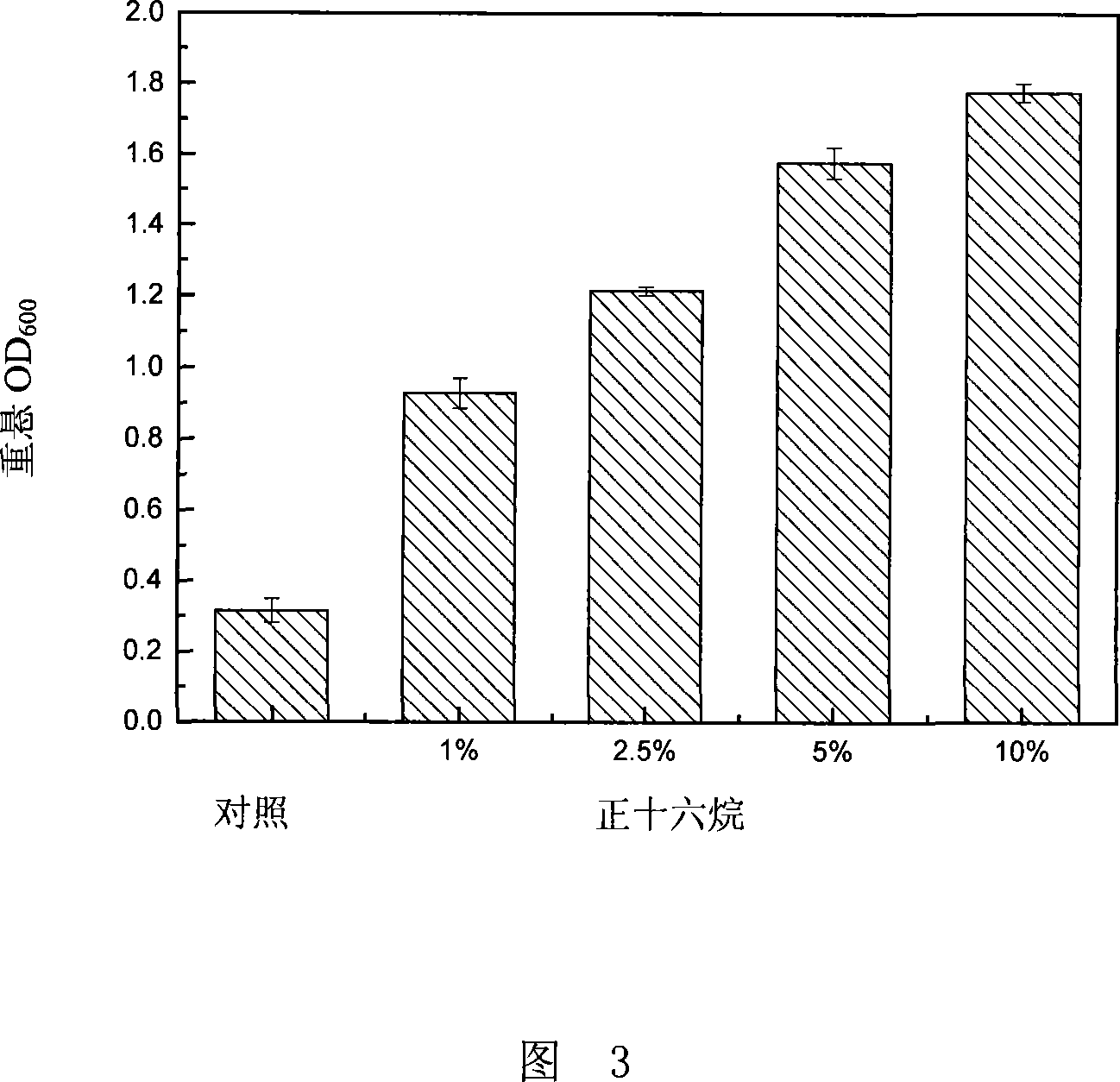

[0021] Embodiment 1, the comparison of the methane-oxidizing bacteria culture method of the present invention and the methane-oxidizing bacteria conventional culture method

[0022] Take the methane-oxidizing bacterium Methylosinus.trichosporium R (CGMCC NO.1894), which was preserved in the General Microbiology Center of China Committee for the Collection of Microbial Cultures on December 21, 2006, referred to as CGMCC, and the address is: North Zhongguancun, Haidian District, Beijing, China One No. 13, the preservation number is CGMCC NO.1894) as an example, compare the cultivation effect of the cultivation method of the present invention and the conventional cultivation method of methane oxidizing bacteria, and the specific process is as follows:

[0023] 1. Routine cultivation of methane-oxidizing bacteria Methylosinus.trichosporium R (CGMCC NO.1894)

[0024] The methane oxidizing bacteria Methylosinus.trichosporium R CGMCC NO.1894 is cultivated by a conventional method, an...

Embodiment 2

[0032] Embodiment 2, the cultivation of methanotrophs

[0033] Methane oxidizing bacteria Methylosinus trichosporium OB3b (ATCC 55314) is cultivated with the method of the present invention, and specific method is as follows:

[0034] 1) Methane solvent saturation treatment of n-hexadecane

[0035] Put 20 mL of n-hexadecane into a 100 mL airtight glass culture bottle with a baffle, and after autoclaving at 121°C for 15 minutes, inject 40 mL of methane into the bottle with a sterilized gas filter with a pore size of 0.2 μm. , shaking at 30° C. and 150 rpm for 12 hours (with methane replenished through a 0.2 μm gas filter every 3 hours), to obtain n-hexadecane saturated with methane.

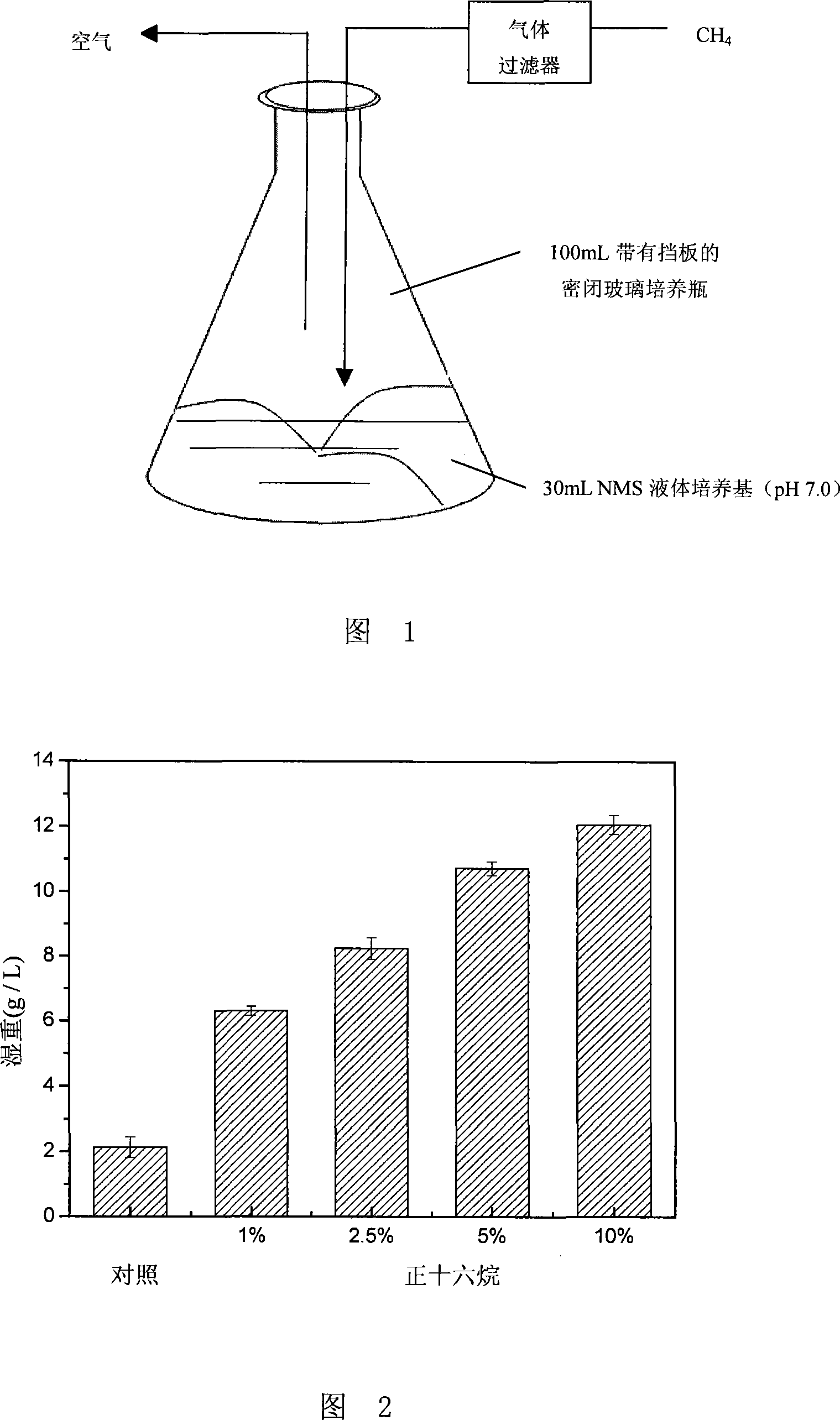

[0036] 2) Using methane-saturated n-hexadecane to cultivate methanotrophs

[0037] In a 100mL airtight glass culture bottle with a baffle, 30mL of NMS liquid medium was subpackaged, then 3mL of n-hexadecane saturated with methane was added, autoclaved at 121°C for 15 minutes, cooled, and then us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com