Method for reducing high concentration doping extension to epitaxial substrate

A high-concentration, substrate technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as processing, no silicon nitride film formation process, silicon oxide thickness, etc., to reduce stress and reduce The effect of out-diffusion of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

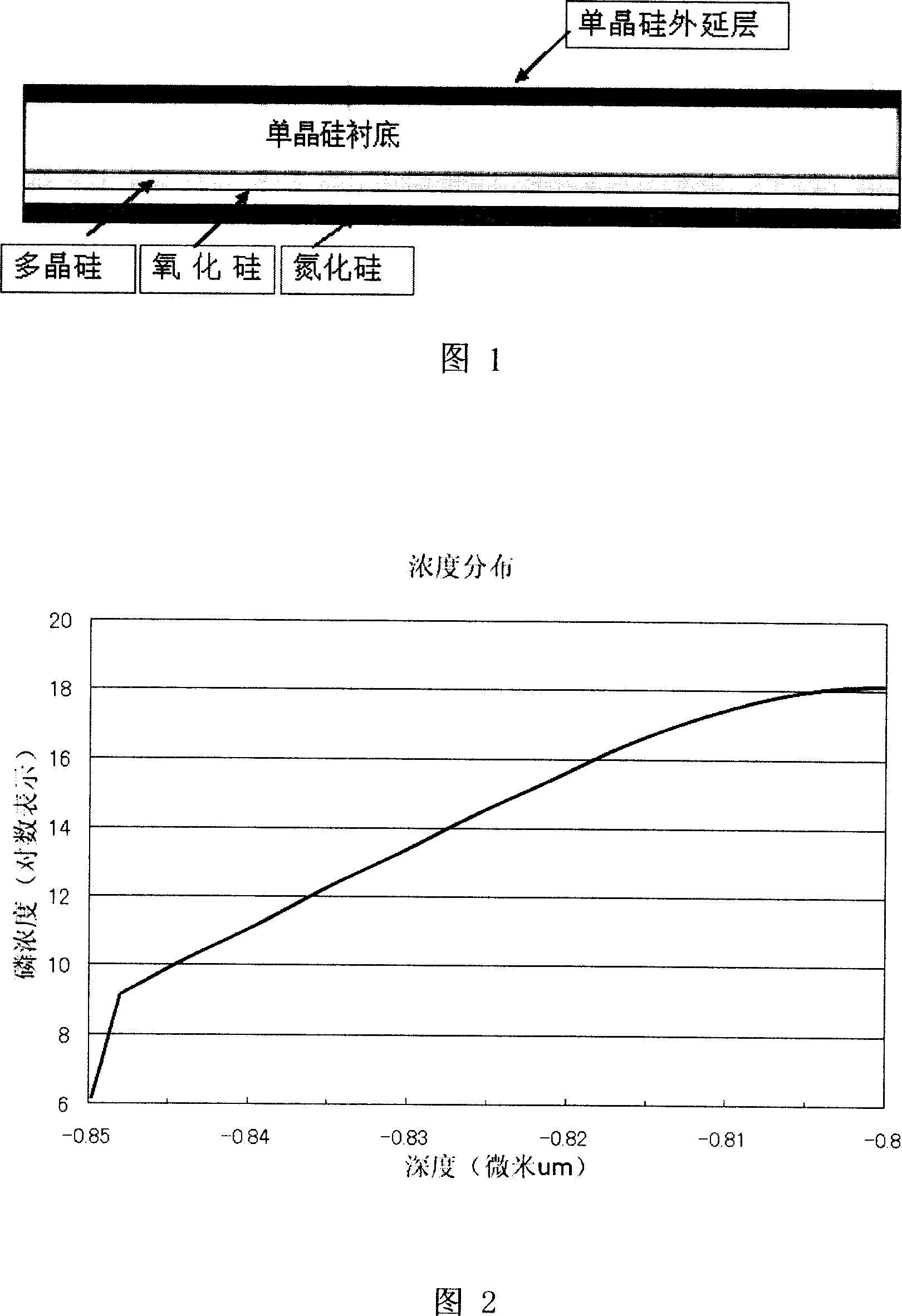

[0019] 1) The substrate is fully cleaned after entering the factory;

[0020] 2) Using low-pressure chemical vapor deposition (CVD) equipment for silicon nitride film growth (500A);

[0021] 3) Scrub both sides of the silicon wafer;

[0022] 4) After entering the dry etching equipment, the silicon nitride on the front side of the silicon wafer is fully etched with carbon tetrafluoride gas;

[0023] 5) After the silicon wafer is fully cleaned, it enters the subsequent processing process.

[0024] Wherein, in step 1), the medicinal solution for cleaning is mainly a combination of diluted hydrogen peroxide+ammonia water and a combination of diluted sulfuric acid+hydrogen peroxide, the purpose of which is to remove organic matter and metal impurities on the surface of the silicon wafer. The interval from step 1) to step 2) is best controlled within 12 hours, otherwise it may affect the cleanliness of the equipment cavity. In step 3), brushing is carried out with a high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com