Nano composite material of asymmetric phthalocyanine and carbon nano-tube and preparation method thereof

A nano-composite material, carbon nanotube technology, applied in the direction of fibrous fillers, dyed low-molecular-weight organic compounds, etc., can solve the problems of unevenness, easy shedding, and difficult to control the degree of nanocomposite, so as to improve the photoconductive performance, optimize the Effects of photosensitivity, excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

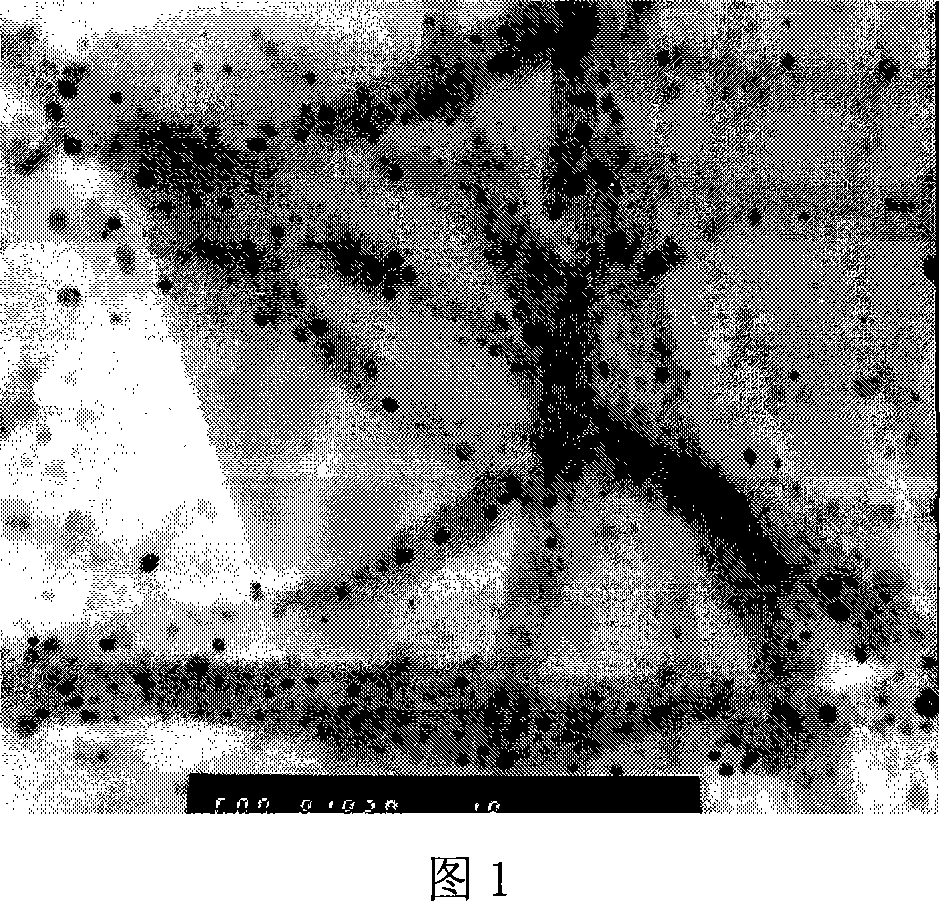

Image

Examples

Embodiment 1

[0019] Add 100 mg of multi-walled carbon nanotubes into a mixed strong acid solution consisting of 100 ml of concentrated sulfuric acid and concentrated nitric acid (volume ratio of 3:1), and after ultrasonic oscillation treatment for 6 hours, slowly pour 500 ml of deionized water (with stirring), and let stand After overnight, it was filtered and washed with deionized water until it became neutral, and dried in an oven. Repeat 3 times to obtain the carbon nanotube material after chemical etching. 100 mg of activated carbon nanotubes were placed in a 150 mL single-necked round bottom flask, 12 mL of silane coupling agent KH-550 and 50 mL of toluene were added, and refluxed at 130° C. for 10 h. The carbon nanotubes were filtered out, washed with methanol and acetone in sequence, and then vacuum-dried at 150° C. to obtain surface-treated carbon nanotubes. Weigh 100 mg of the above-mentioned surface-treated carbon nanotubes and disperse them in 30 mL of freshly steamed N, N'-dim...

Embodiment 2

[0021] Same as Example 1, but the silane coupling agent KH-550 is changed to hexanediol

Embodiment 3

[0023] Same as Example 1, but the silane coupling agent KH-550 is changed to hexamethylenediamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com