Method for extracting and separating mixed metal particles in high-voltage electrostatic field

A high-voltage electrostatic field and mixed metal technology, which is applied in electrostatic effect separation, chemical instruments and methods, and solid separation, can solve the problems of poor purification effect, high energy consumption, and unsuitability for medium and small-scale metal purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

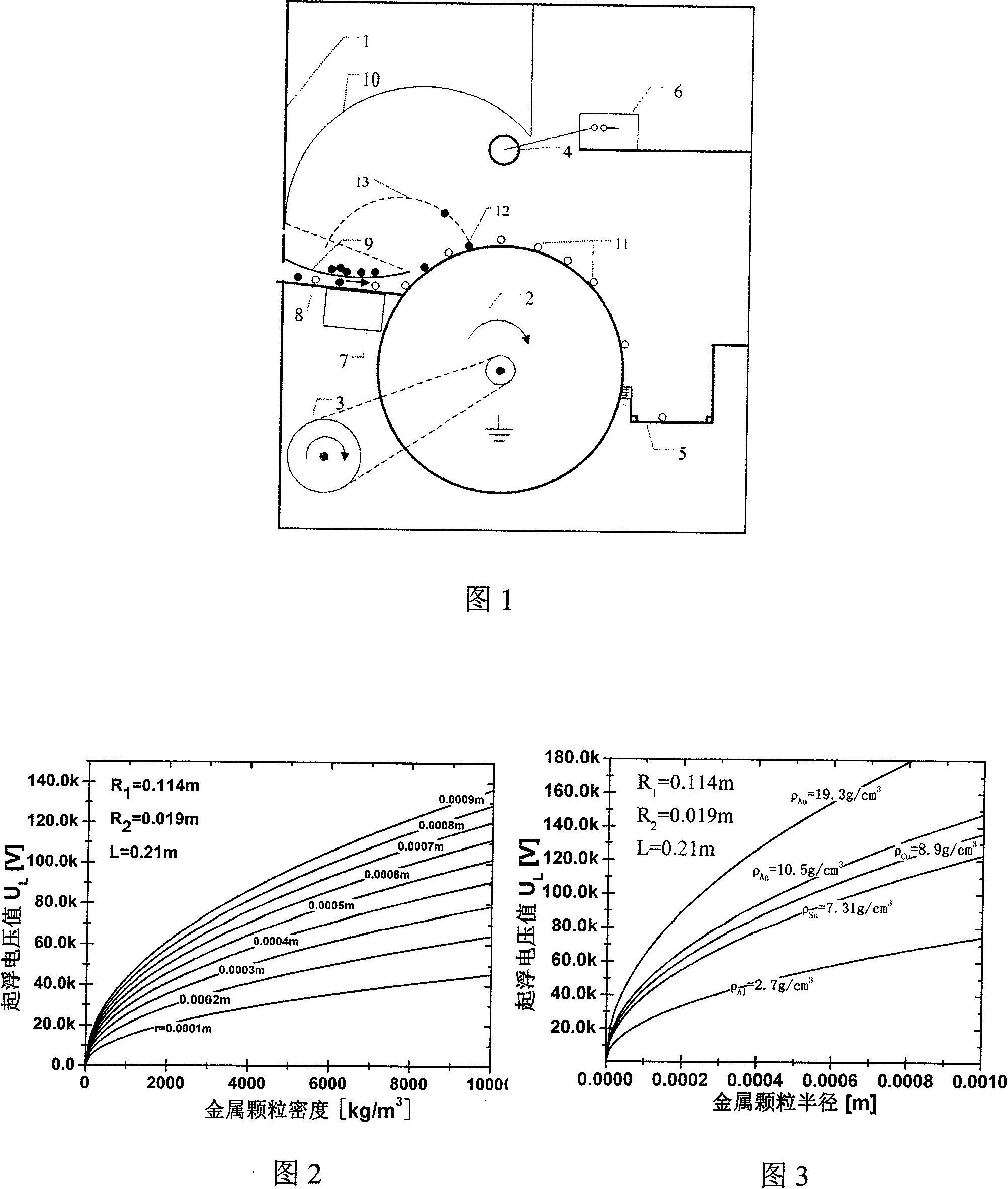

Image

Examples

Embodiment 1

[0042] Metal purity (quantity ratio) and grade (mass ratio) after the purification of embodiment 1

[0043] mineral powder

Embodiment 1 purity (Q.%)

Example 1 Grade (wt.%)

Cu

86~91

88~93

Al

91~95

89~94

[0044] After purification and sorting, take out the metal powders in collection tank a and collection tank b for purity analysis, the method is: take out 3 parts of copper powder randomly (different positions) from the collection tank a with a small medicine spoon, and the volume of each part is approximately equal, and then manually separate copper particles and aluminum particles with a magnifying glass for each part, and count the number of copper particles n after separation 1 , the total number of particles taken out is n, then the purity of copper is n 1 / n, do this for each copy, and take the average. The number of simultaneous pairs is n 1 The copper particles and the weight of the part taken ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com