Freezed boiled chestnut kernel processing technics

A processing technology, chestnut technology, applied in the direction of freezing/refrigerating preservation of fruits/vegetables, food preservation, food preparation, etc., can solve problems such as retention, low economic benefits, backward deep processing technology, etc., to achieve good products, mature technology, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in further detail below with reference to the drawings and specific embodiments.

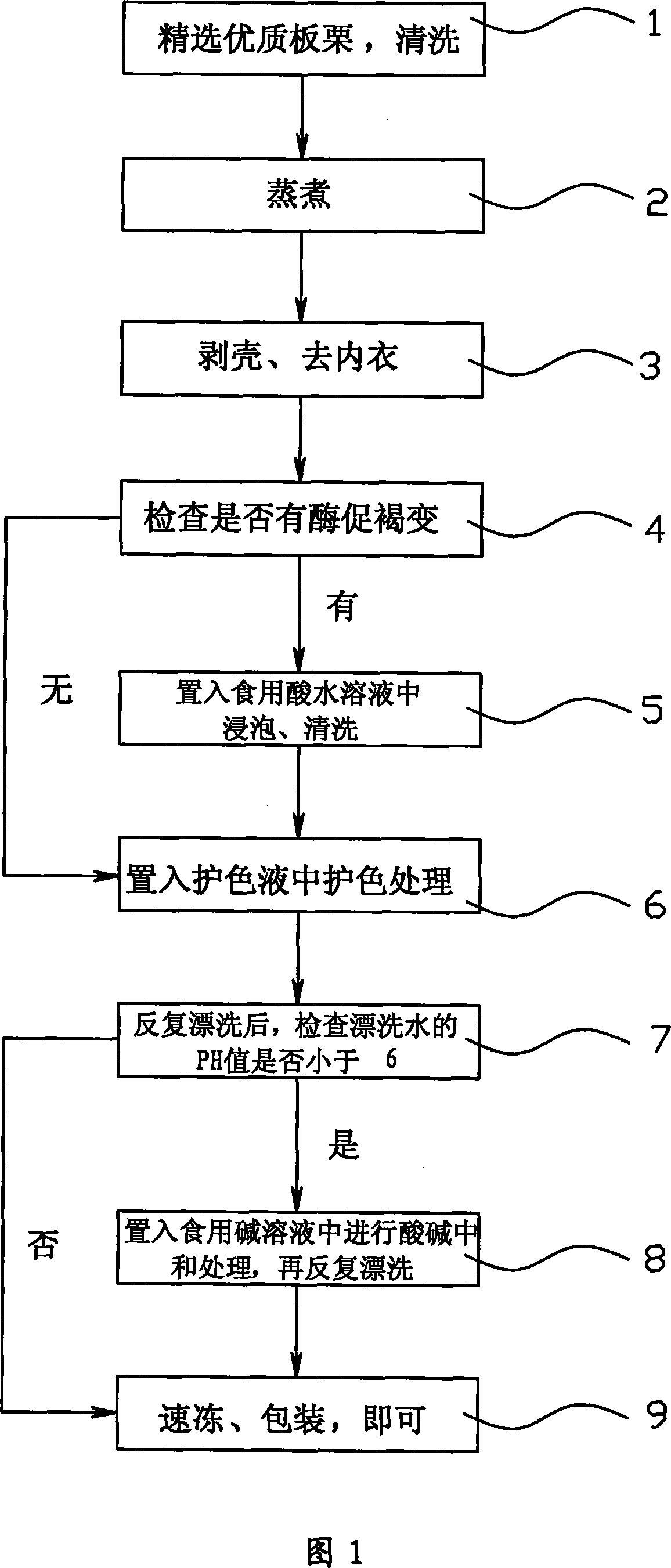

[0032] As shown in Figure 1, a kind of frozen boiled chestnut kernel processing technology, this processing technology comprises the following steps:

[0033] Step 1. Using fresh or refrigerated chestnuts as raw materials, pick out moth-eaten chestnuts, moldy chestnuts, rotten germinated chestnuts and other low-quality chestnuts, select high-quality chestnuts, and fully clean the selected high-quality chestnuts with a soaking machine to remove mud and dirt. Entrained sundries, chestnut I;

[0034] Step 2. Put the chestnut I into a cooking machine, keep the temperature above 95°C under normal pressure, and cook for 2 minutes to obtain the chestnut II;

[0035] This step is mainly in order to kill the activity of polyphenol oxidase (PPO) in the chestnut, in order to avoid producing enzymatic browning;

[0036] Step 3. Manua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com