Process for extracting effective component of sweet tea

An extraction method and a technology of active ingredients, which are applied in the field of extraction of active ingredients of sweet tea, can solve problems affecting the quality of sweet tea extracts, difficult recovery of solvents, and easy residues of finished products, etc., and achieve the effects of improving comprehensive utilization, simple operation, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Add 0.3 kg of compound enzyme (among them, 0.18 kg of cellulase, 0.06 kg of hemicellulase, and 0.06 kg of pectinase) into 1.5 kg of water at a temperature of 35° C. to activate for 5 minutes to obtain a compound enzyme preparation;

[0017] Take 100 kg of sweet tea leaves and put them into 500 kg of water at 40°C, adjust the pH value of the water to 4.5 with citric acid, then slowly add the above compound enzyme preparation, stir gently, and enzymolyze for 1.5 hours;

[0018] 2) Heating the obtained enzymolysis solution to 75°C and maintaining the temperature for 8 minutes to inactivate the enzyme, and then hydraulically filtering the enzymolysis solution to obtain a filtrate;

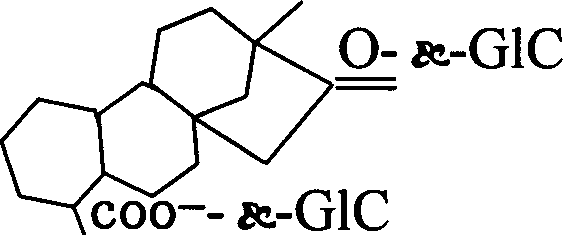

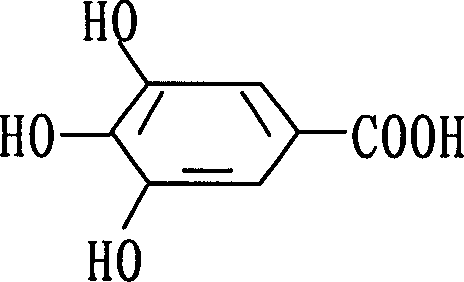

[0019] 3) The filtrate is separated by ultrafiltration through a hollow ceramic membrane device with a pore size of 10,000 molecular weight cut-off, to obtain a retentate and a separation liquid, and the obtained retentate is a polymer substance such as ellagitannin, which is purified by chrom...

Embodiment 2

[0023] 1) 0.5 kg of compound enzyme (including 0.4 kg of cellulase and 0.1 kg of protease) was added to 3 kg of water at a temperature of 45° C. to activate for 10 minutes to obtain a compound enzyme preparation;

[0024] Take 100 kg of sweet tea leaves and put them into 1000 kg of water at 55°C, adjust the pH value of the water to 6 with citric acid, then slowly add the above-mentioned compound enzyme preparation, stir gently, and enzymolyze for 3 hours;

[0025] 2) Heating the obtained enzymatic hydrolysis solution to 95°C and maintaining the temperature for 15 minutes to inactivate the enzyme, and then hydraulically filtering the enzymatic hydrolysis solution to obtain a filtrate;

[0026] 3) The filtrate is separated by ultrafiltration through a hollow ceramic membrane device with a pore size of 10,000 molecular weight cut-off, to obtain a retentate and a separation liquid. The retentate is a macromolecular substance such as ellagitannin, which is purified, removed, and dri...

Embodiment 3

[0030] 1) Put 100 kg of sweet tea leaves into 500 kg of water at 50°C, and adjust the pH value of the water to 4.5 with citric acid, then slowly add 0.3 kg of compound enzyme (wherein, fiber 0.18 kg of primease, 0.05 kg of hemicellulase, 0.03 kg of pectinase, and 0.04 kg of protease) were activated for 10 minutes, and the compound enzyme preparation obtained was gently stirred and enzymolyzed for 2 hours;

[0031] 2) Heating the obtained enzymolysis solution to 75°C and maintaining the temperature for 10 minutes to inactivate the enzyme, then hydraulically filtering the enzymolysis solution to obtain a filtrate;

[0032] 3) The filtrate is separated by ultrafiltration through a hollow ceramic membrane device with a pore size of 10,000 molecular weight cut-off, to obtain a retentate and a separation liquid, and drying the retentate to obtain an ellagitannin product;

[0033] 4) separating the separated liquid obtained by ultrafiltration separation through hollow ceramic membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com