Process for producing polymer solar battery

A technology of solar cells and polymers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficulties and complex crystallization properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

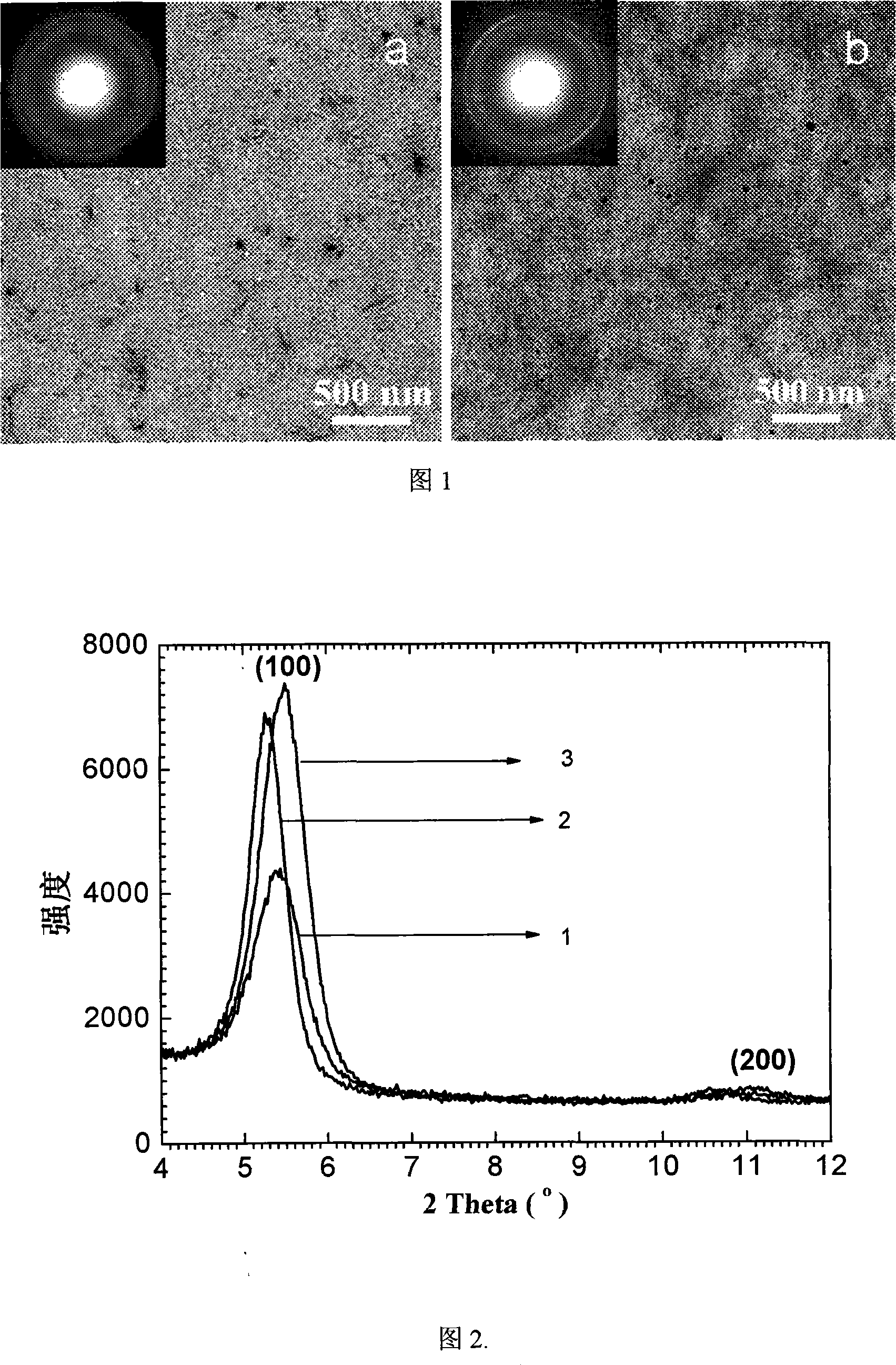

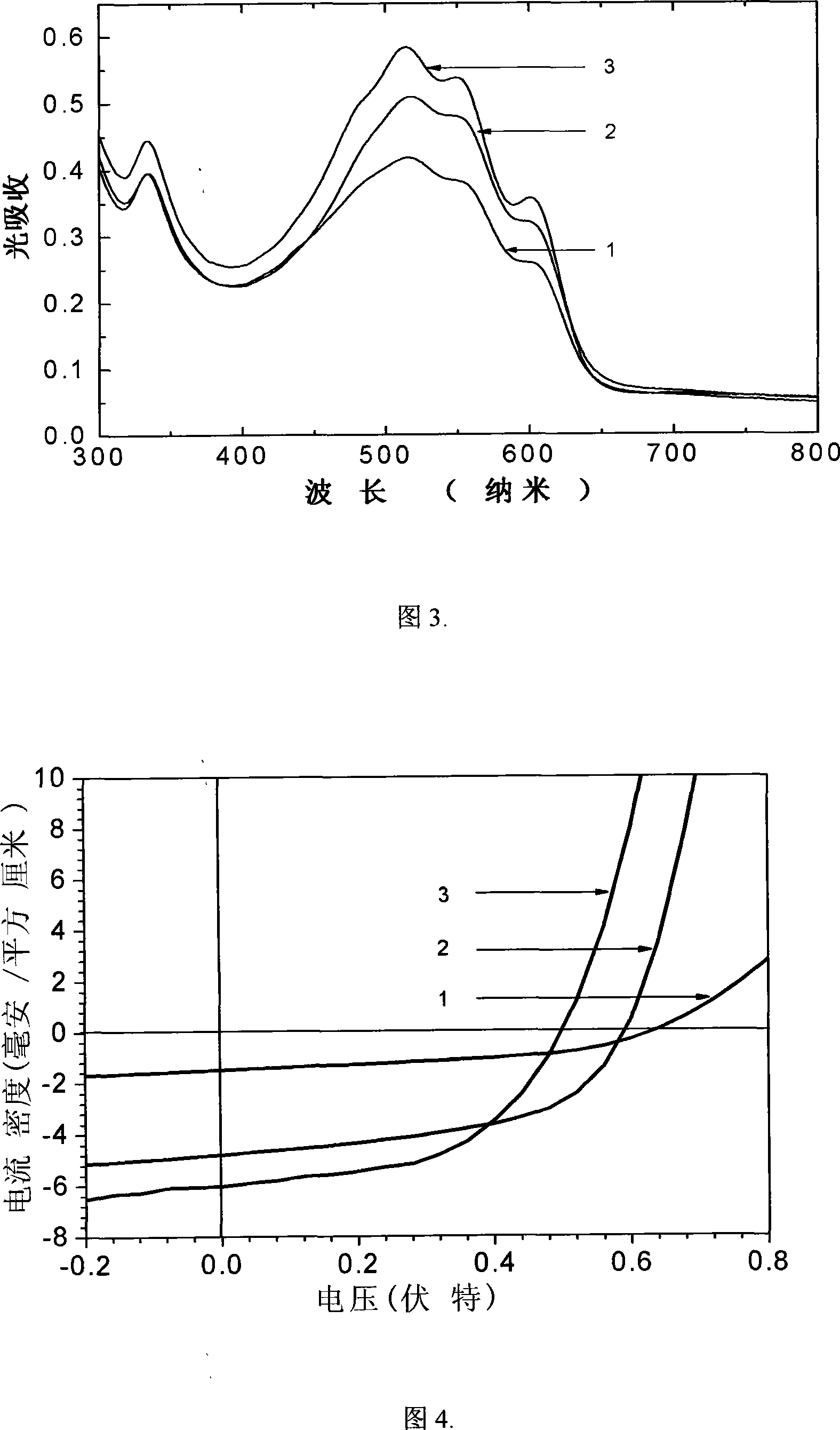

[0015] Embodiment 1: at room temperature, P3HT is dissolved in good solvent o-dichlorobenzene (ODCB) under stirring conditions, and is made into a solution of 8.0 mg / ml; then the poor solvent n-hexane is slowly added dropwise to the solution obtained above 10 times. alkane, the volume ratio of the amount of poor solvent added to the good solvent is 0.03:1-0.1:1, and the total amount added is 0.5 ml of n-hexane / ml of ODCB solution. After each addition of the poor solvent, let the solution stir for 30 minutes at a stirring speed of 200 rpm, so that the P3HT in the solution reaches the dissolution equilibrium. Carry out 12 hours, add the PCBM equivalent to the mass of 1 times the amount of P3HT dissolved in the solution into the solution, and stir for 6 hours at a stirring speed of 500rpm to prepare a mixed solution with a P3HT:PCBM mass ratio of 1:1, Finally, the obtained solution is spin-coated with a rotary film-spinning machine to form a film, and a polymer solar cell is obta...

Embodiment 2

[0016] Embodiment 2: at room temperature, P3HT is dissolved in good solvent o-dichlorobenzene (ODCB) under stirring conditions, and is made into a solution of 10.0 mg / ml; then the poor solvent ring is slowly added dropwise to the solution obtained above 15 times. For hexane, the volume ratio of the amount of poor solvent added to the good solvent is 0.02:1-0.1:1, and the total amount added is 1 ml of cyclohexane / ml of ODCB solution. After each addition of the poor solvent, let the solution stir for 10 minutes at a stirring speed of 100 rpm, so that the P3HT in the solution reaches the dissolution equilibrium. When the last poor solvent is added, the solution is stirred at a speed of 100 rpm. Carry out 6 hours, add the PCBM equivalent to the mass of 0.5 times the amount of P3HT dissolved in the solution into the solution, and stir for 2 hours at a stirring speed of 1000 rpm to prepare a mixed solution with a P3HT:PCBM mass ratio of 2:1, Finally, the obtained solution is spin-co...

Embodiment 3

[0017]Embodiment 3: at room temperature, P3HT is dissolved in good solvent o-dichlorobenzene (ODCB) under stirring condition, and is made into a solution of 5.0 mg / ml; Then, in the solution of above-mentioned gained, the poor solvent alcohol is slowly added dropwise 5 times. , the volume ratio of the amount of poor solvent added to the good solvent is 0.02:1-0.1:1, and the total amount of the added amount is 0.2 ml of alcohol / ml of ODCB solution. After each addition of the poor solvent, let the solution stir for 60 minutes at a stirring speed of 500 rpm, so that the P3HT in the solution reaches the dissolution equilibrium. After adding the poor solvent for the last time, let the solution in the dark place at a stirring speed of 500 rpm. Carry out 24 hours, add the PCBM equivalent to the mass of 2 times the amount of P3HT dissolved in the solution into the solution, and stir for 16 hours at a stirring speed of 200rpm to prepare a mixed solution with a P3HT:PCBM mass ratio of 1:2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com