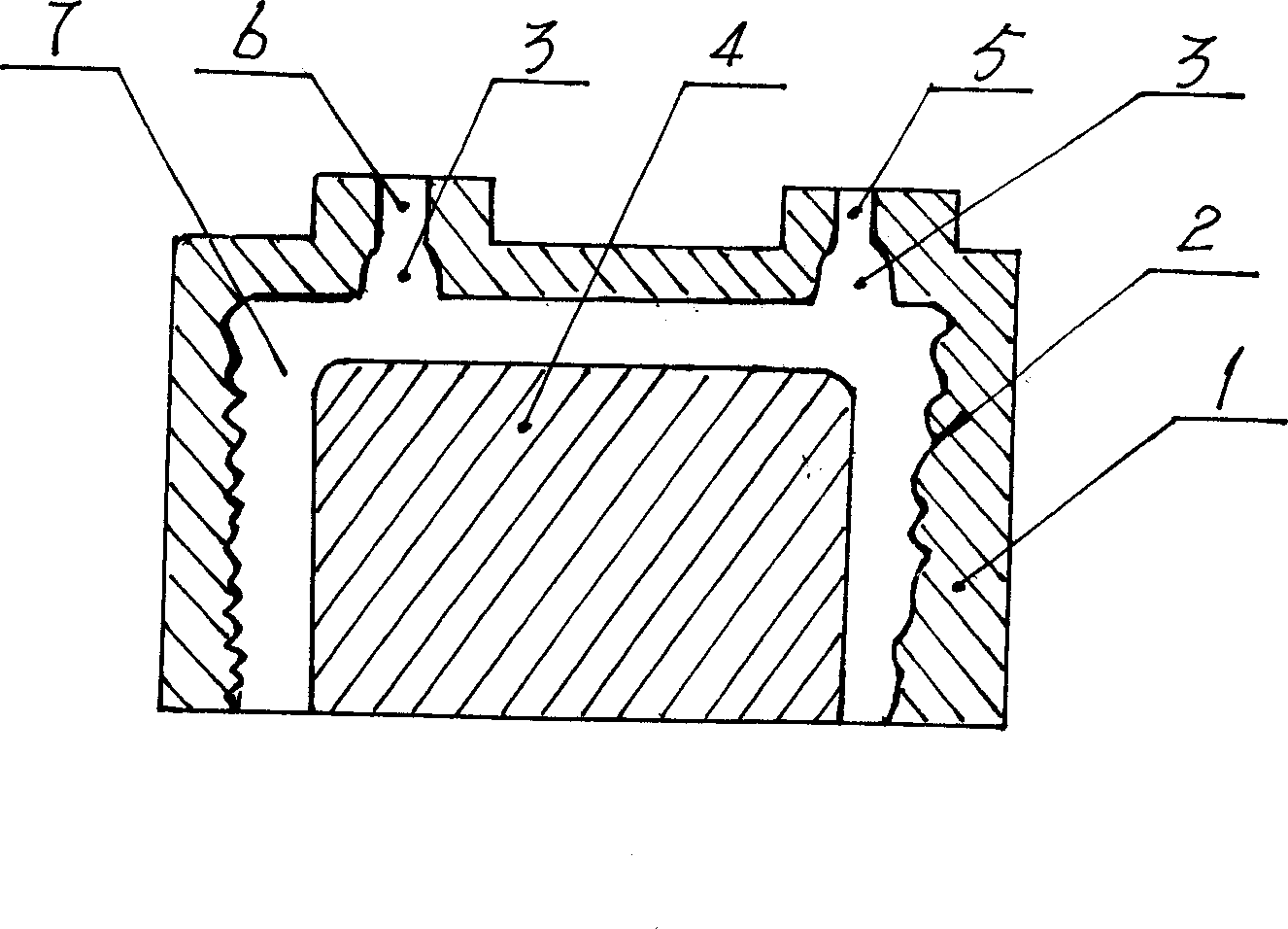

Pseudo stone flower bowl and method for making the same

A flowerpot and quasi-stone technology, which is applied in the field of artificial stone flowerpots and its production, can solve the problems of poor stability, anticorrosion, poor weather resistance, no industrialization, and high cost, achieve excellent fire resistance, reduce product Weight, the effect of improving the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] (1) Selection of materials, select materials according to the following weight ratio:

[0028] 1. Magnesium chloride aqueous solution 25kg, its concentration is 22 degrees, measures with hydrometer;

[0029] ② Magnesium oxide 35kg; ③ Iron red 0.5kg; ④ Iron black 0.5kg; ⑤ Iron yellow 0.5kg;

[0030] ⑥urea-formaldehyde resin 0.1kg; ⑦silica sol 0.1kg; ⑧wood chips 1kg;

[0031] (2) Preparation of pouring materials:

[0032] The first step: add urea-formaldehyde resin and silica sol into the magnesium chloride aqueous solution and stir evenly;

[0033] Step 2: Mix the powdered magnesium oxide, iron red, iron black, iron yellow and sawdust evenly;

[0034] Step 3: Put the solution obtained in the first step into the powder obtained in the second step and stir thoroughly to obtain the pouring material;

[0035] (3) Preparation method of soft mold coating:

[0036] The iron red, iron black, and iron yellow are mixed with an appropriate amount of magnesium chloride aqueous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com