Well dynamic liquid level auto detector

A detector and liquid level technology, applied in measurement, borehole/well components, earthwork drilling and production, etc., can solve the problems of large sound velocity error and sound source can only be operated manually, and achieve the effect of strong amplitude and short duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] (1) Liquid level measurement process

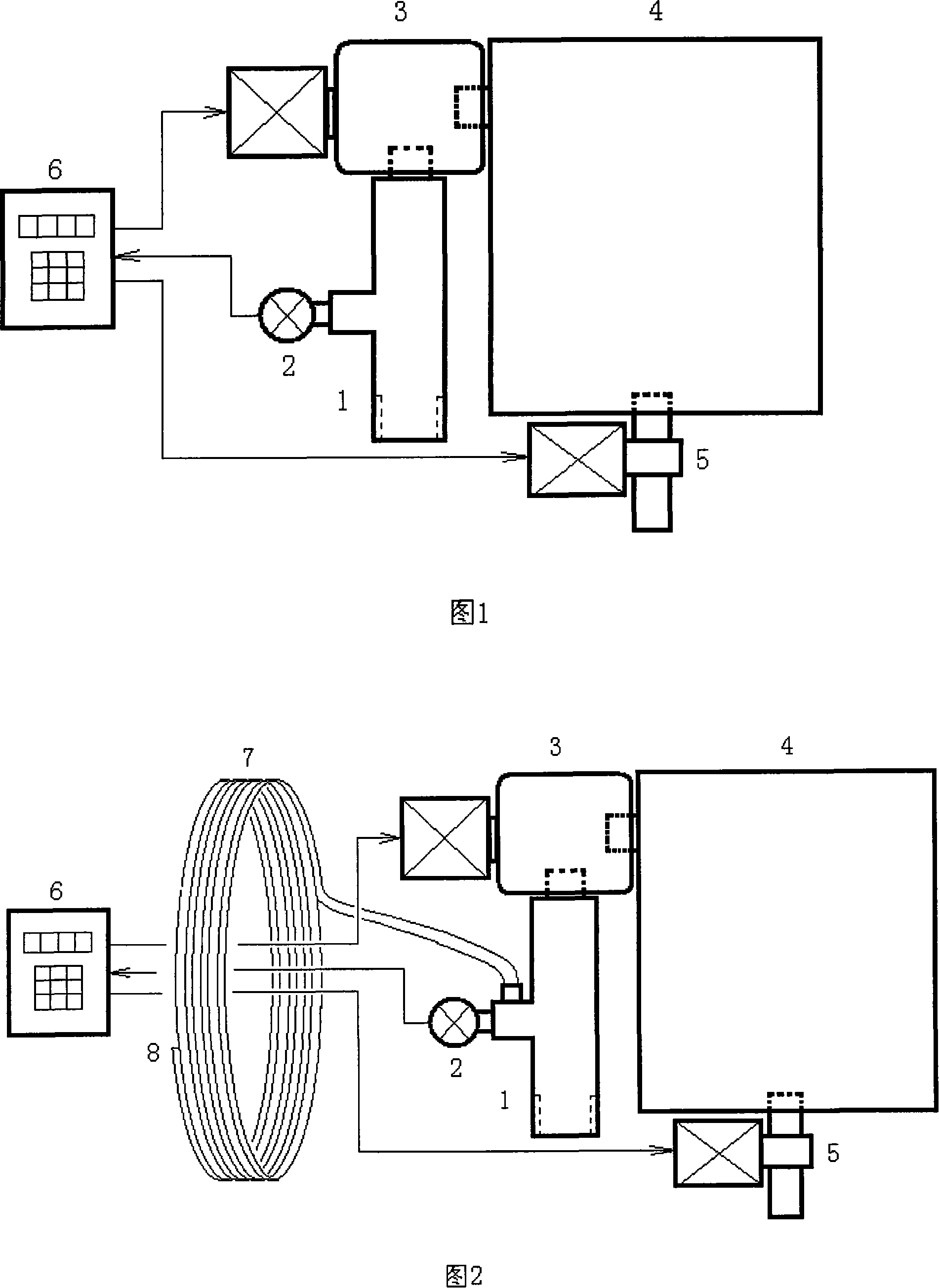

[0020] When the oil well casing pressure is higher than 0.1MPa, the liquid level measurement process is as follows. See Fig. 1, the electronic unit 6 controls the solenoid valve 5 to open, and the pressure of the container 4 drops. After the electromagnetic valve 5 is opened and the pressure of the container 4 is low to the test tube pressure of 0.1 MPa, the electromagnetic valve 5 is closed to get ready for the test. Then the electronic unit 6 controls the solenoid valve 3 to open and close quickly, so that a negative pressure wave is formed in the cavity of the test tube 1 . The pressure in the cavity of the test tube 1 is continuously collected by the sensor 2 into the electronic unit 6 to form a waveform. When the negative pressure wave propagates downhole and reflects back from the liquid surface, an obvious liquid level echo can be observed on the waveform; at the same time, the negative pressure wave will also generate ech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com