Process for nondestructively measuring nano grain stress condition

A nanoparticle and stress state technology, applied in the field of X-ray measurement, can solve the problem of inability to measure and obtain nanoparticle stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Take the extended X-ray absorption fine structure spectroscopy EXAFS measurement of the stress of silver nanoparticles in glass as an example:

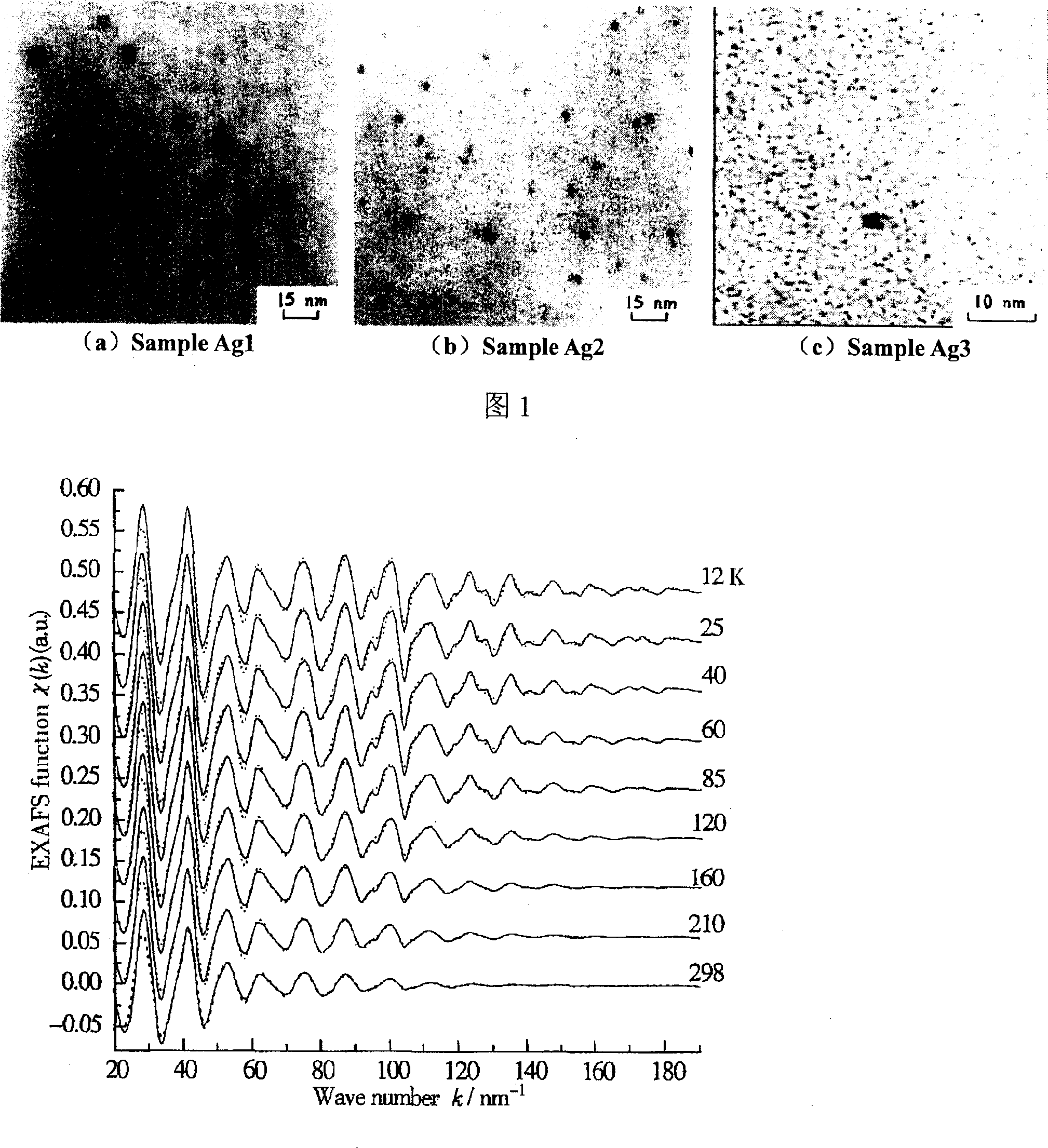

[0016] 1. Preparation of silver nanoparticle glass: Three silver nanoparticle glass samples were prepared by ion exchange method, namely Ag1, Ag2, and Ag3, and the silver nanoparticles in the samples Ag1, Ag2 and Ag3 were observed by Phillips CM200 transmission electron microscope (TEM). 7nm, 4nm and 2.8nm respectively (see Figure 1).

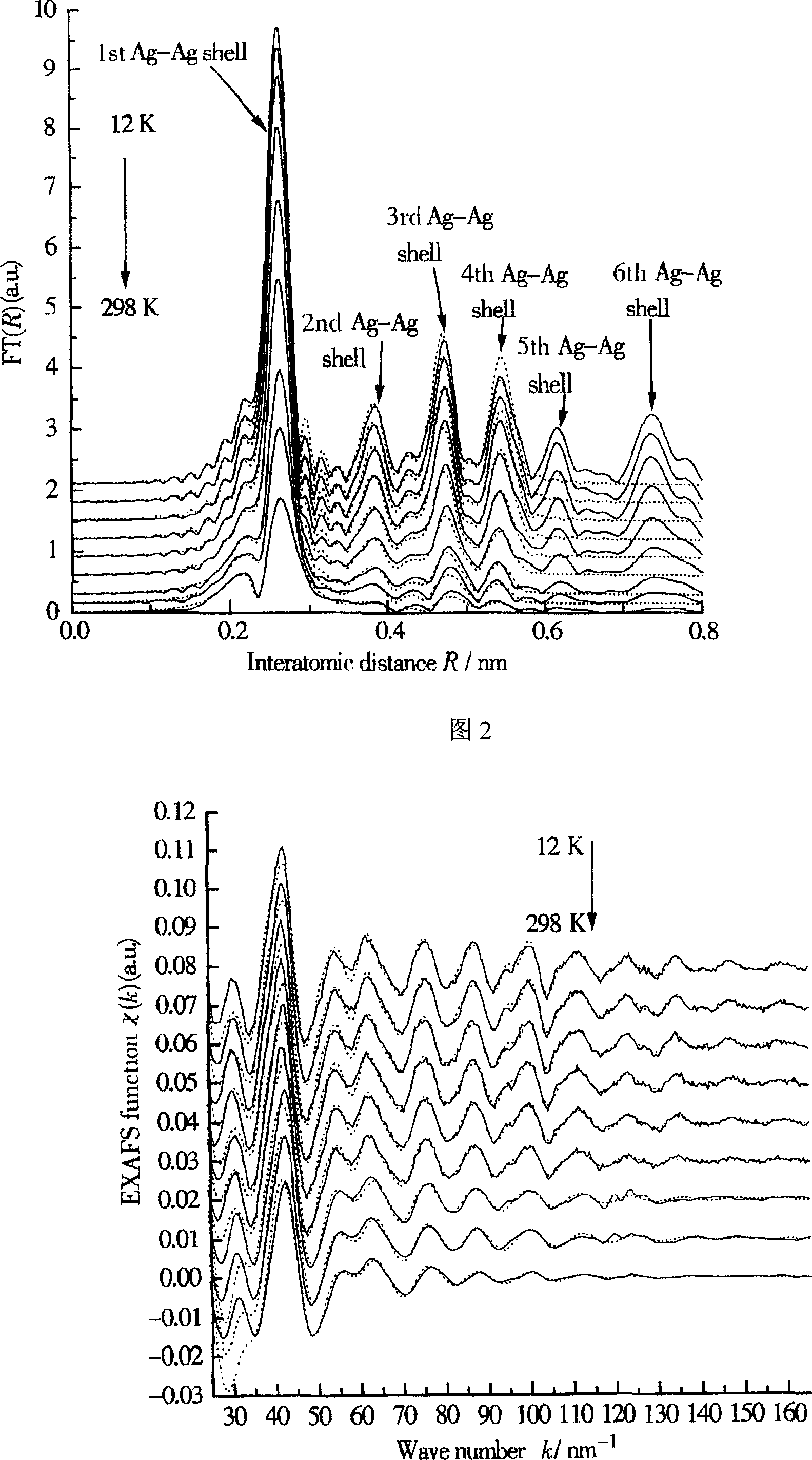

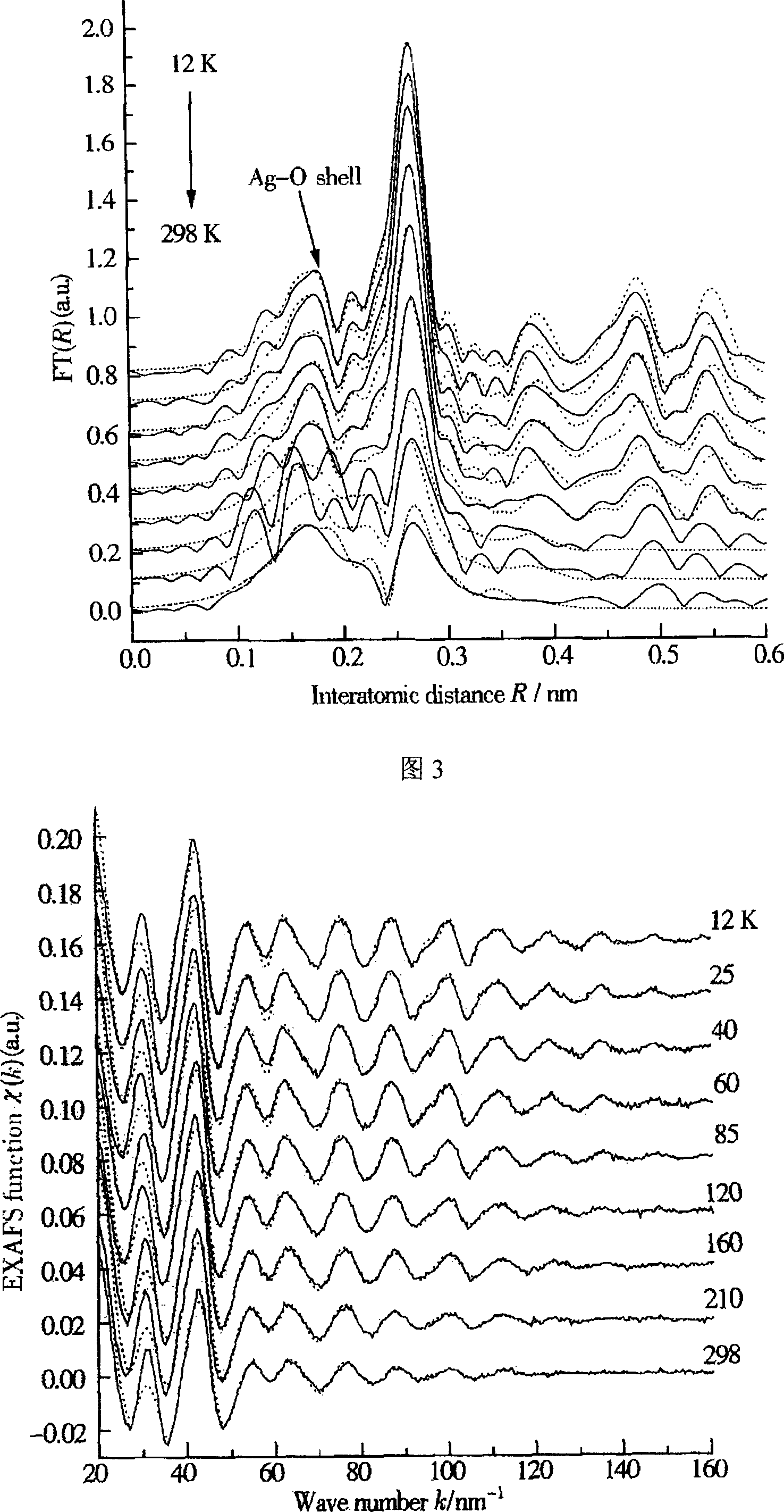

[0017] 2. Characterization of silver nanoparticle structure: the measurement temperature range is 12K-298K. Ag K-edge X-ray absorption fine structure spectra were analyzed with the commercial UWXAFS3.0 package. Ag K-edge X-ray absorption fine structure spectra were collected at the X1 experimental station of the Synchrotron Radiation Center in Hamburg, Germany. The theoretical phase function and amplitude function of Ag were calculated using the theoretical EXAFS equation, and they were used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com