Non-woven fabrics composite economical master batch and its producing method and device

A non-woven and economical technology, applied in the field of non-woven fabrics, can solve the problems of long residence time of materials, extremely high production process requirements, and limited application, and achieve the effect of saving energy and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation

[0043] Weigh 15kg of polypropylene resin with a melting index of 90, 8kg of polypropylene resin with a melting index of 3, 60kg of nano-scale activated calcium carbonate, 9kg of polyethylene wax, 0.6kg of composite antioxidant, 2kg of zinc stearate, titanate 2kg, white oil 1.7kg, rutile titanium dioxide 1.7kg.

[0044] 2. Ingredients

[0045] Put the above-mentioned raw materials in a stirring container according to the proportion, and stir and mix evenly.

[0046] 3. Forming

[0047] Send the well-mixed compound into the twin-screw extruder to make it fully mixed, melted, dispersed and extruded. During this process, the temperature is controlled by circulating water.

[0048] 4. Granulation

[0049] The molded product extruded by the twin-screw extruder is sent to the single-screw extruder, and the finished non-woven fabric is obtained through melt extrusion, pelletizing, and vibrating sieve screening, and can be packaged.

Embodiment 2

[0051] 1. Preparation

[0052] Weigh 15kg of polypropylene resin with a melting index of 60, 8kg of polypropylene resin with a melting index of 30, 60kg of nano-scale activated calcium carbonate, 9kg of polyethylene wax, 0.6kg of composite antioxidant, 2kg of zinc stearate, titanate Coupling agent 2kg, white oil 1.7kg, rutile titanium dioxide 1.7kg.

[0053] The rest are the same as Example 1.

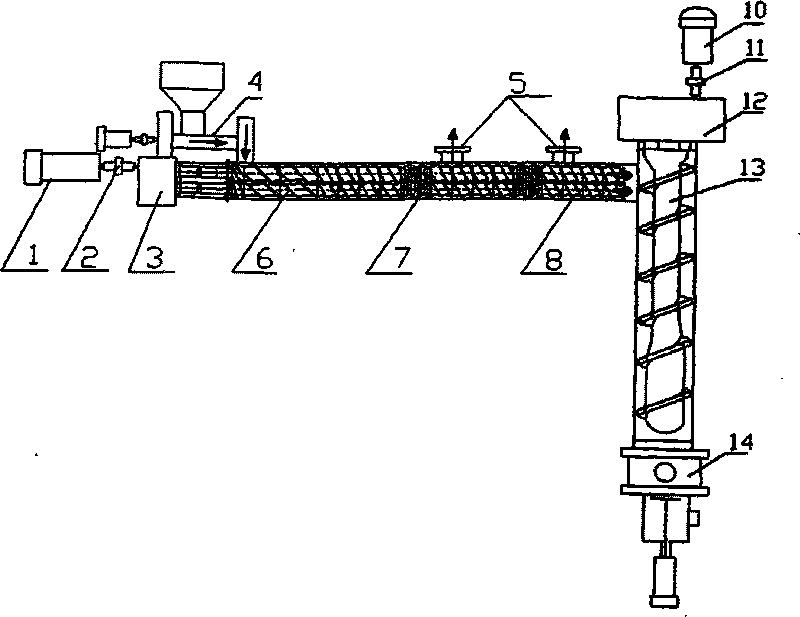

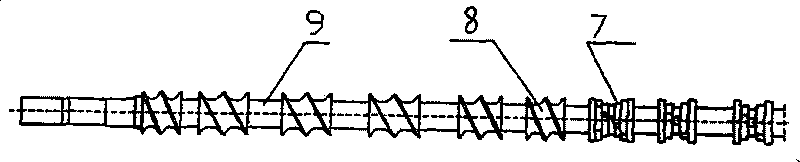

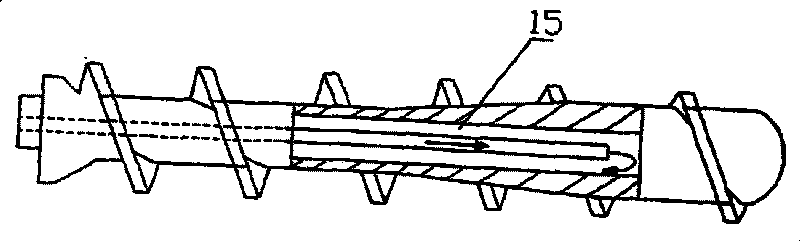

[0054] The above production process uses a stepped screw extruder, its structure is as follows figure 1 shown. The stepped screw extruder consists of a first-stage twin-screw extruder and a second-stage single-screw extruder. The first-stage twin-screw extruder and the second-stage single-screw extruder are arranged in a "T" shape, and the outlet of the first-stage twin-screw extruder is connected to the inlet of the second-stage single-screw extruder. The material ends are connected.

[0055]The first-stage twin-screw extruder is mainly composed of a drive motor I1, a shaft coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com