Surface treatment technique for enhancing viscose fiber wet strength

A viscose fiber and surface treatment technology, applied in fiber treatment, synthetic fibers, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

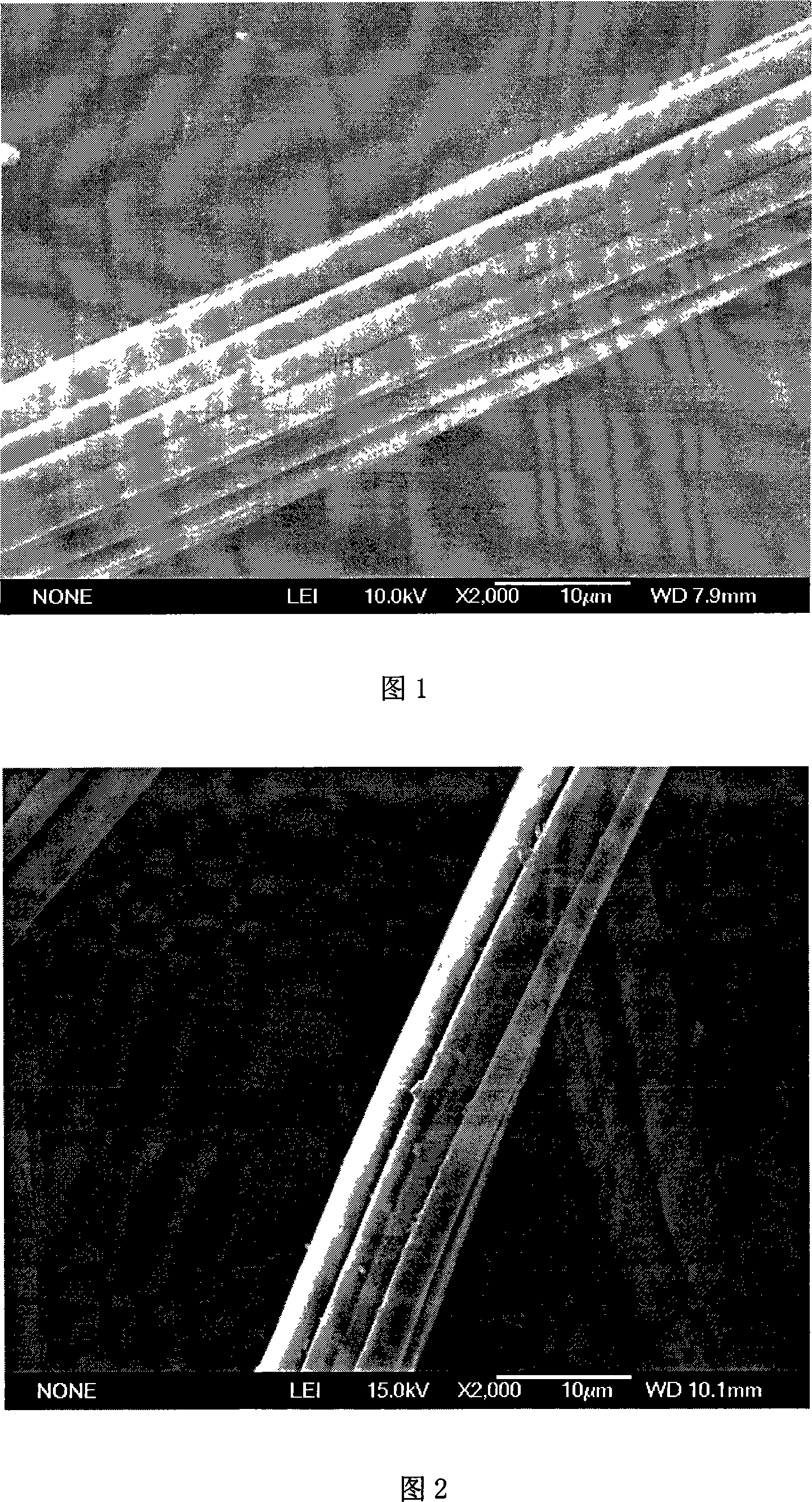

Image

Examples

Embodiment 1

[0023] (1) Take 0.1 part of potassium permanganate (parts by weight, 100 parts of water), add deionized water and stir for 1 min at 40°C to 50°C to make a fiber surface activation treatment solution for use;

[0024] (2) Take 50 parts of acrylamide, add deionized water and stir at 60°C to 80°C for 5 minutes, use sulfuric acid to adjust the pH value to 3.5, and make a fiber wet strength enhancement surface treatment solution for use;

[0025] (3) Add 45 parts of glutaraldehyde into deionized water and stir for 5 minutes at 60°C to 80°C to prepare a surface chelation treatment solution for use;

[0026] (4) Place the pretreated fibers such as cleaning, degumming, and drying in the treatment tank of the surface activation treatment solution prepared in the above (1), and immerse them for 20 to 30 minutes at 40°C to 50°C;

[0027] (5) Lead the impregnated fiber out of the treatment tank, wash it until there is no obvious pink color, and then pass it through the treatment tank equi...

Embodiment 2

[0032] According to the process of Example 1, take 0.2 parts of potassium permanganate, 50 parts of polyhexamethylene adipate; then take 45 parts of glutaraldehyde, and carry out wet strength enhancement treatment on the surface of viscose fiber to obtain high wet strength of viscose fiber.

Embodiment 3

[0034] According to the process method of Example 1, take 0.2 parts of potassium permanganate and 50 parts of polyacrylamide with a low degree of polymerization; then take 45 parts of glutaraldehyde, and carry out wet strength enhancement treatment on the surface of viscose fiber to obtain high wet strength polyacrylamide Viscose fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com