Making method for blue top organic LED based on electronic acceptance material

A technology of electron acceptor materials and light-emitting diodes, which is applied in the direction of electrical solid-state devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing the luminous efficiency of devices, achieve convenient transmission and recombination, improve luminous brightness and efficiency, and high Effects of Luminous Brightness and Luminous Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation process of the present invention is:

[0033] A) Vacuum-deposit one or two layers of hole transport material on the cleaned ITO (tin indium oxide, as anode) glass substrate.

[0034] B) Vacuum evaporation of an exciplex elimination material on the hole transport material layer.

[0035] C) Vacuum-evaporating a blue light-emitting material with strong electron-withdrawing ability on the exciplex elimination material.

[0036] D) Vacuum evaporation of a cathode layer on the blue luminescent material.

[0037] The present invention has the following characteristics:

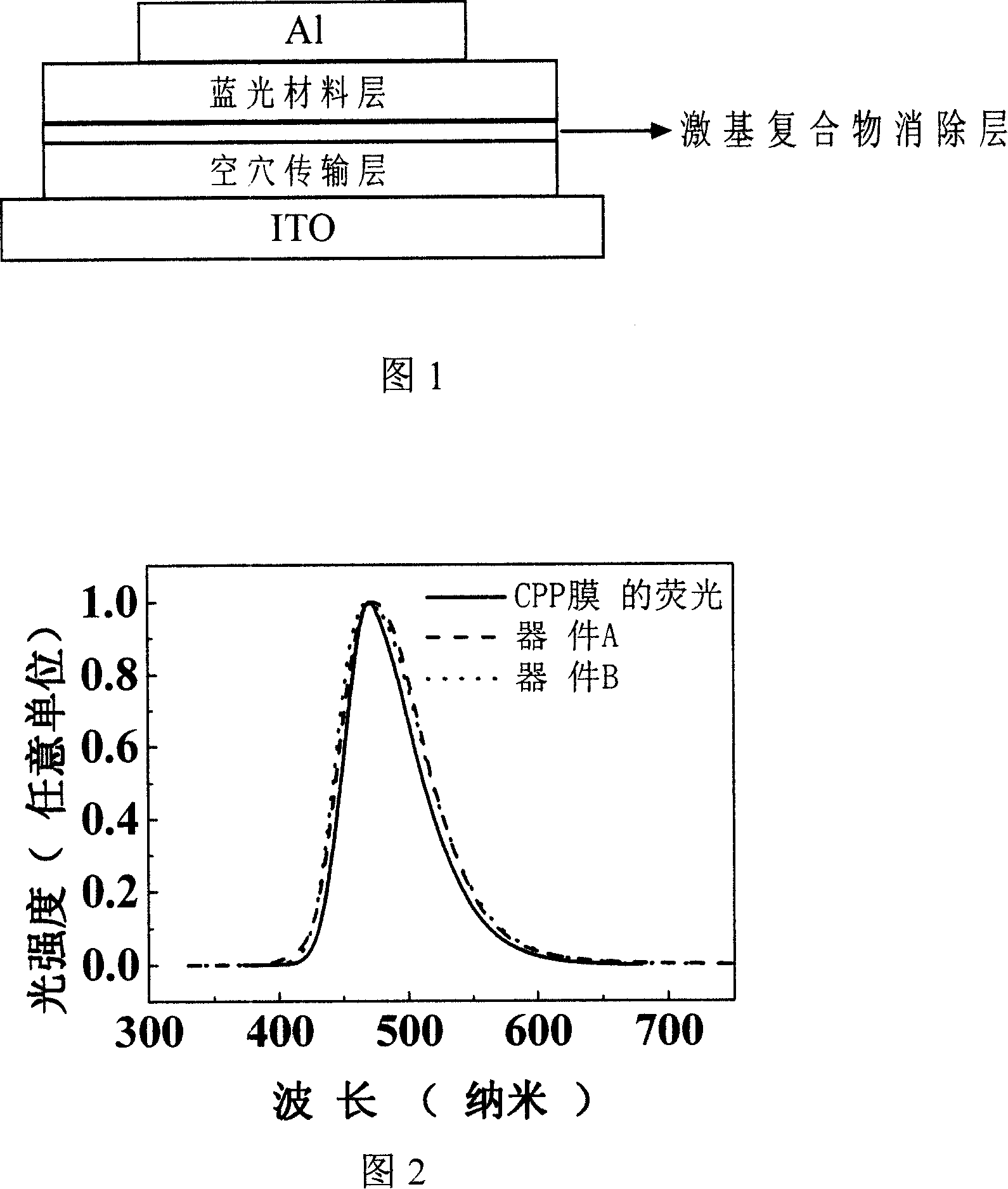

[0038] 1. The device structure includes: ITO anode, hole transport layer (HTL), exciplex elimination layer, electron acceptor material layer (EML) emitting blue light, and metal cathode.

[0039] 2. The blue light-emitting material is an electron acceptor material, which has a strong electron-absorbing ability, and is easy to combine with commonly used hole transport materials such as 4,4'-...

Embodiment 1

[0045] The anode used in the device is ITO, and the cathode is aluminum (Al), but the cathode is not limited thereto, and may also be metals such as lithium, calcium, barium, magnesium, and silver. The structure of the constructed device is shown in Figure 1.

[0046] Implementation steps:

[0047] The first step: cleaning of ITO glass

[0048] The ITO glass was washed with detergent, tap water, deionized water, acetone, and absolute ethanol in sequence, and then dried in an oven.

[0049] Step 2: Evaporate the organic layer

[0050]Place the ITO glass piece in the vacuum chamber, at 4×10 -4 Under the vacuum condition of Pa, each organic layer is deposited at a rate of 1 Ȧ / s, and the evaporation sequence is the hole transport layer, the exciplex elimination layer, and the blue light material layer. For the reference device, no evaporated exciplex removal layer is required.

[0051] Step 3: Cathode Preparation

[0052] An Al cathode is evaporated on the ITO substrate on w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com