Method for preparing semi-interpenetrating network gel polymer electrolyte thin film

A technology of semi-interpenetrating network and gel polymer, which is applied in the field of preparation of gel polymer electrolyte film, and achieves the effects of simple method, stable system performance and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

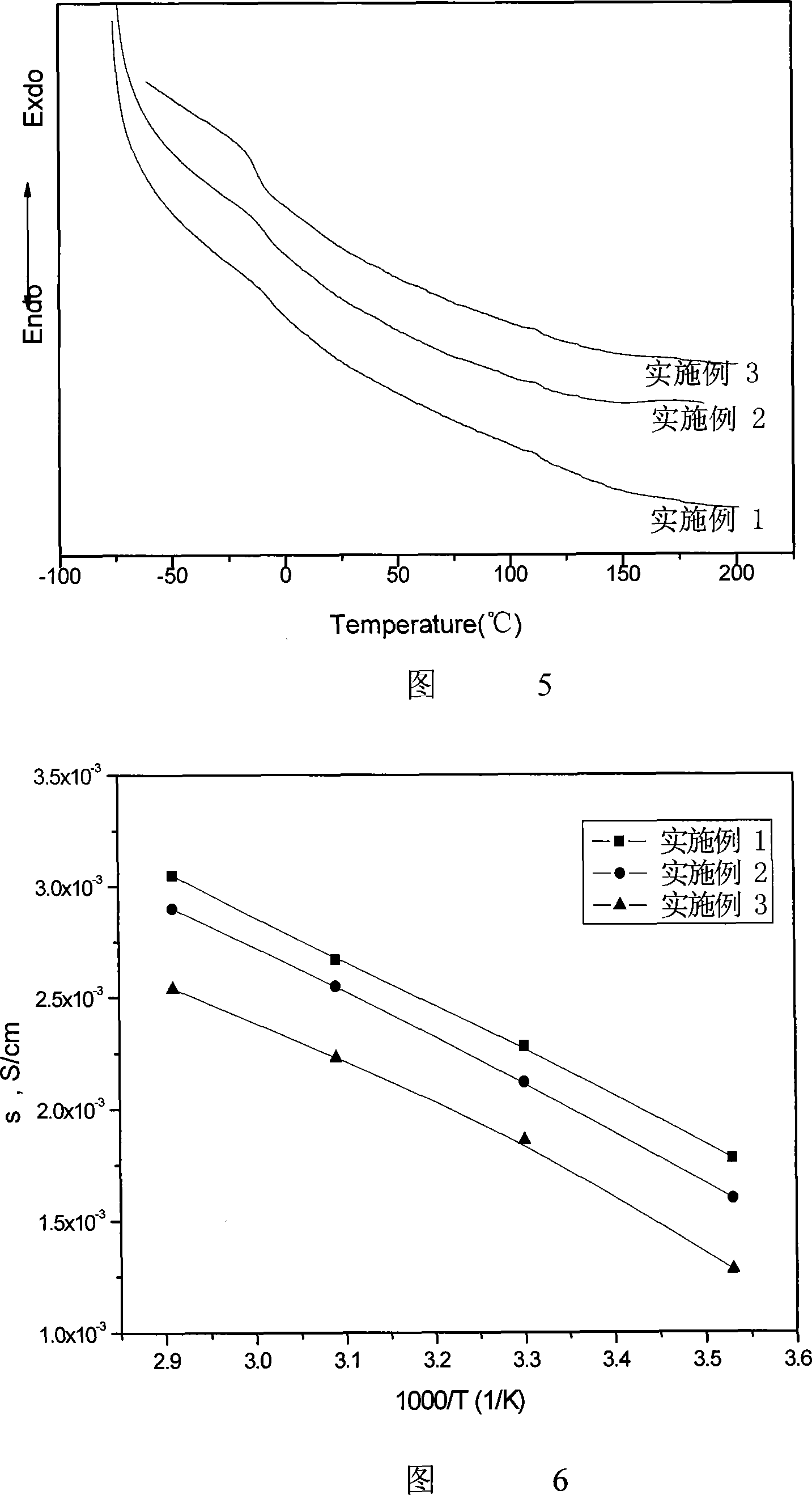

Embodiment 1

[0021] (1) Mix 9.92g of methacryloxypropyltrimethoxysilane with 1.44g of deionized water, add 0.05g of p-toluenesulfonic acid, stir until completely dissolved, then heat up to 40°C for 4 hours to obtain transparent A viscous liquid which is the hydrolyzed cross-linked product of methacryloxypropyltrimethoxysilane. After cooling, add about 2.27g polyethylene glycol dimethacrylate and 0.4g photoinitiator Darocur 1173 to the hydrolyzed cross-linked product, stir together for 0.5 hour, and mix well to obtain a blended prepolymer.

[0022] (2) Weigh 4g of nitrile rubber and dissolve it in 100ml of THF, stir until completely dissolved and uniform, and prepare a nitrile rubber solution with a concentration of 0.04g / ml.

[0023] (3) Weigh about 0.8 g of the blended prepolymer prepared in step (1) and 5 ml of the nitrile rubber solution prepared in step (2), and stir until they are evenly mixed. The mixture was then poured into a Telfon pan, and the solvent was evaporated in a drying ...

Embodiment 2

[0029] (1) Mix 9.92g of methacryloxypropyl trimethoxysilane with 2.16g of deionized water, add 0.06g of p-toluenesulfonic acid, stir until completely dissolved, then raise the temperature to 40°C for 3 hours to obtain a transparent A viscous liquid which is the hydrolyzed cross-linked product of methacryloxypropyltrimethoxysilane. After cooling, add about 1.81g polyethylene glycol dimethacrylate and 0.55g photoinitiator Darocur1173 to the hydrolyzed cross-linked product, stir together for 1 hour, and mix well to obtain a blended prepolymer.

[0030] (2) With the step (1) in the embodiment 1.

[0031] (3) Weigh about 0.6 g of the blended prepolymer prepared in step (1), and 10 ml of the nitrile rubber solution prepared in step (2), and stir until they are evenly mixed. The mixture is then poured into a Telfon pan, and the solvent is volatilized in a drying oven to obtain a blended prepolymer film, and the film is irradiated with ultraviolet light to initiate polymerization for...

Embodiment 3

[0034] (1) Mix 9.92g of methacryloxypropyltrimethoxysilane with 3.6g of deionized water, add 0.07g of p-toluenesulfonic acid, stir until completely dissolved, then raise the temperature to 40°C for 5 hours to obtain transparent A viscous liquid which is the hydrolyzed cross-linked product of methacryloxypropyltrimethoxysilane. After cooling, add about 1.3g of polyethylene glycol dimethacrylate and 0.74g of photoinitiator Darocur 1173 to the hydrolyzed crosslinked product, stir together for 1 hour, and mix well to obtain a blended prepolymer.

[0035] (2) With the step (1) in the embodiment 1.

[0036] (3) Weigh about 0.4g of the blended prepolymer and 15ml of nitrile rubber solution, and stir until they are evenly mixed. The mixture is then poured into a Telfon pan, and the solvent is volatilized in a drying oven to obtain a blended prepolymer film, and the film is irradiated by ultraviolet light to initiate polymerization for 0.4 hours (ultraviolet light power W=110watts, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com