Process using microchannel technology for conducting alkylation or acylation reaction

A microchannel, reactant technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, carbon compound catalysts, etc., can solve problems such as expensive downstream purification procedures, achieve reduction of unfavorable coking, efficient mixing, Highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

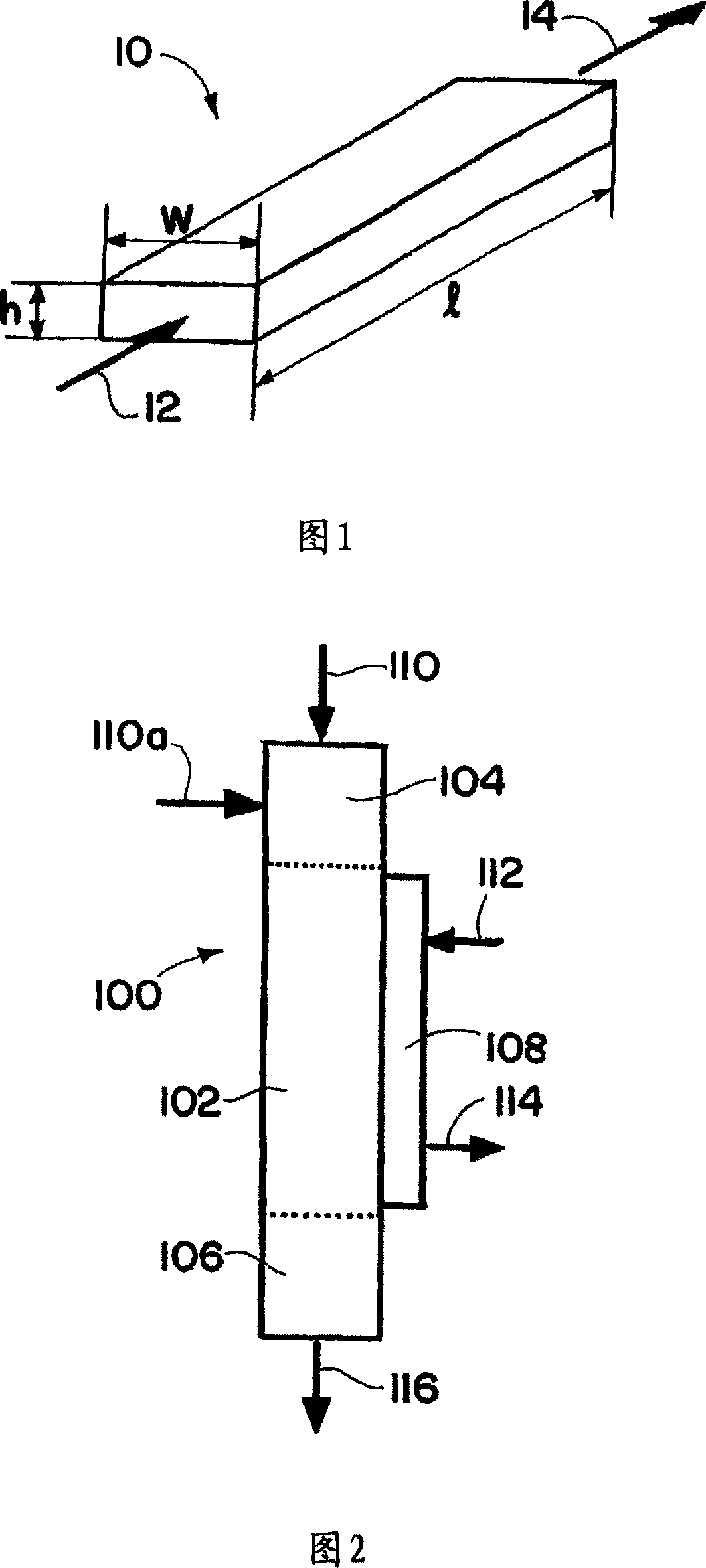

[0184] A process microchannel with a height of 2 mm, a width of 25.4 mm and a length of 30.5 cm had a ZSM-5 zeolite catalyst layer with a coating of 0.25 micron thickness on the inner wall of the catalyst layer. A benzene and ethylene premixed feed containing 1 mole of ethylene for every 2 moles of benzene flows through the process microchannels. The temperature of the feed mixture at the inlet was 500°C. At airspeeds over about 10,000hr -1 Under the operating process microchannel, the total ethylbenzene production is estimated to be about 99%.

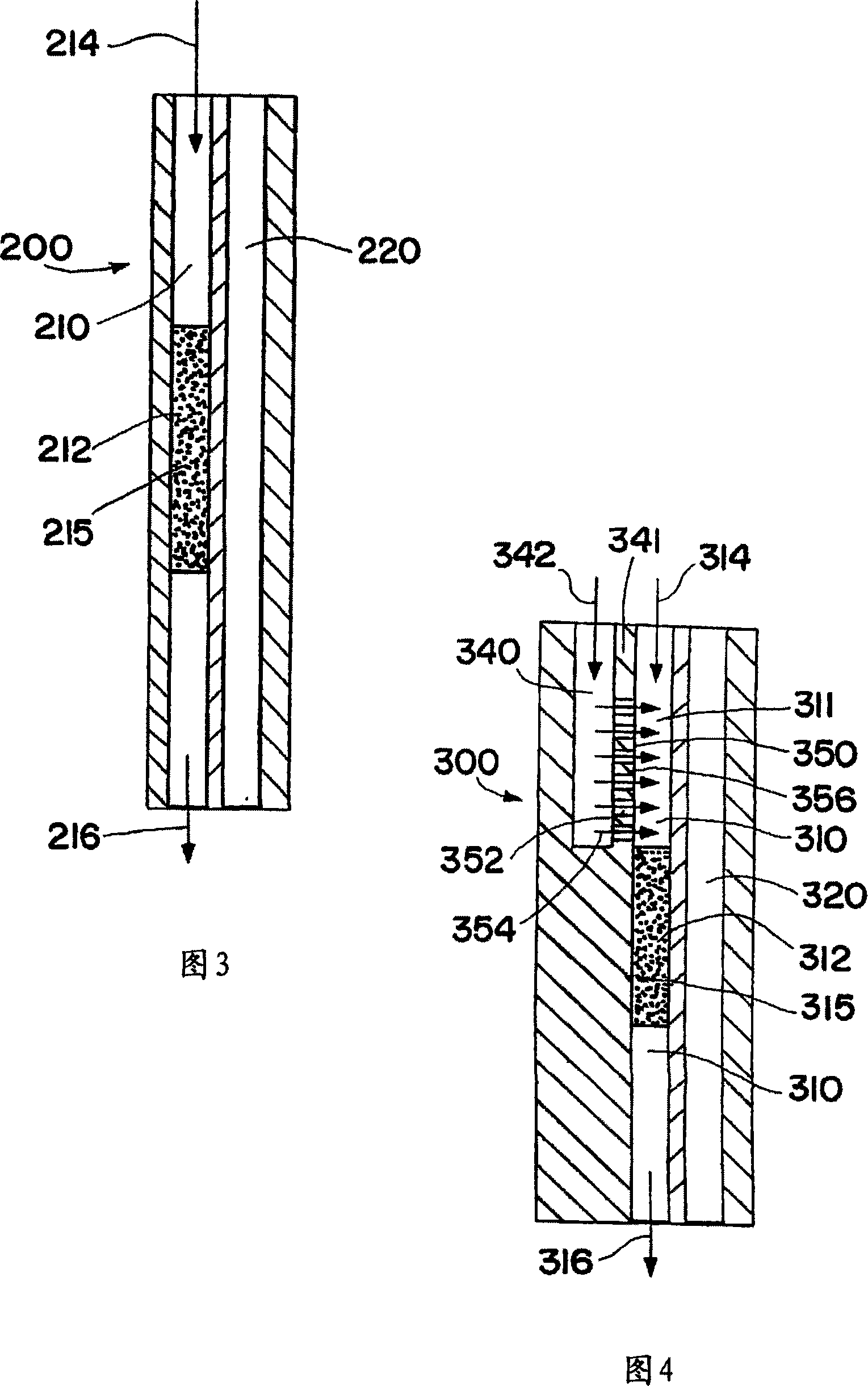

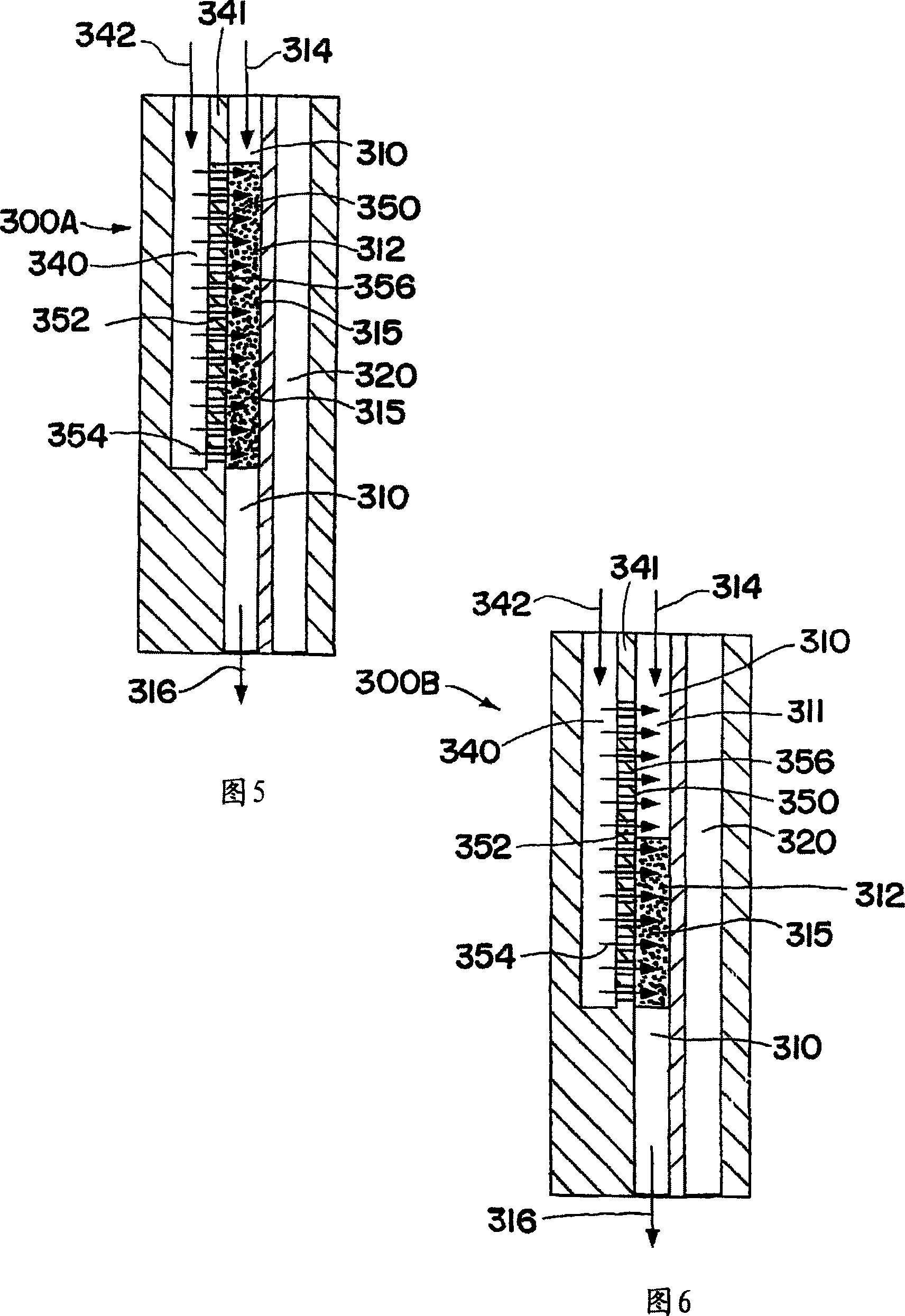

[0185] In one embodiment, the catalyst can be regenerated. This catalyst regeneration may be performed by passing a regeneration fluid through process microchannels (210, 310, 410) to contact the catalyst. The regeneration fluid may comprise hydrogen or a stream of diluted hydrogen. Diluents may include nitrogen, argon, steam, methane, carbon dioxide, or mixtures of two or more thereof. H in regeneration fluid 2 The concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com