Device for separating ice and crystal

A separation device and ice crystal technology, applied in other dairy products, dairy products, food preparation, etc., can solve the problems of slow ice crystal discharge, poor ice crystal separation effect, high content, etc., to reduce solute loss, save energy consumption, improve separation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

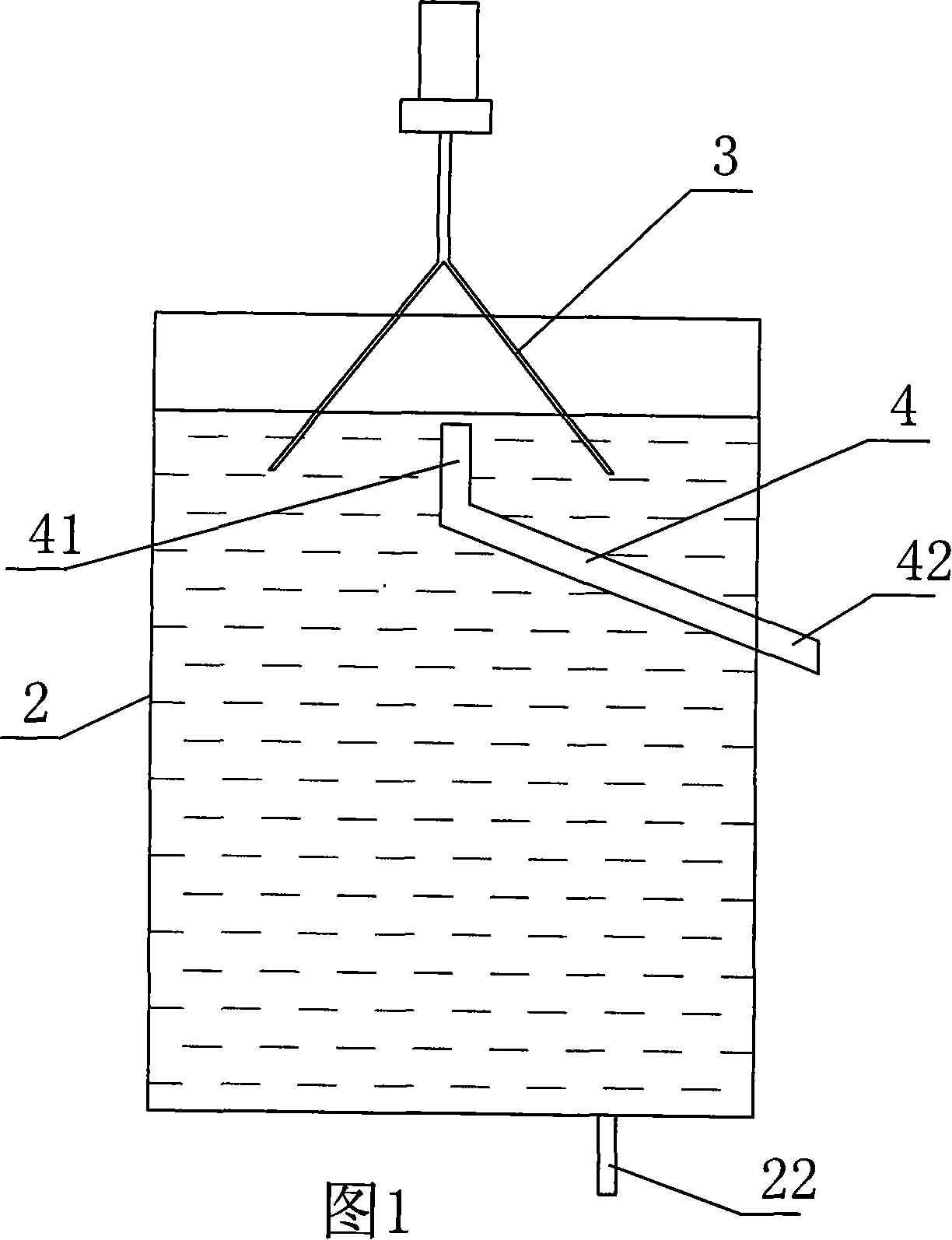

[0025] As shown in Figure 1, it is a schematic diagram of the structure of Embodiment 1 of the present invention, which includes a tank body 2 for holding ice crystals and liquid mixture materials, and is characterized in that: the upper part of the tank body is provided for rotating the liquid surface in the tank body. A moving surface stirrer 3, the surface stirrer is in a bifurcated shape, so that when the surface of the liquid is rotated, the ice crystals with a lighter density can gather towards the center under the action of the centripetal force generated by the rotation; the tank is also equipped with Hollow ice crystal collecting pipe 4, the ice crystal collecting port 41 of the ice crystal collecting pipe is located in the rotating center of the liquid level in the tank, and the ice crystal discharge port 42 leads to the outside of the tank body.

[0026] The opening of the ice crystal collecting port faces upward.

[0027]The ice crystal discharge port protrudes fro...

Embodiment 2

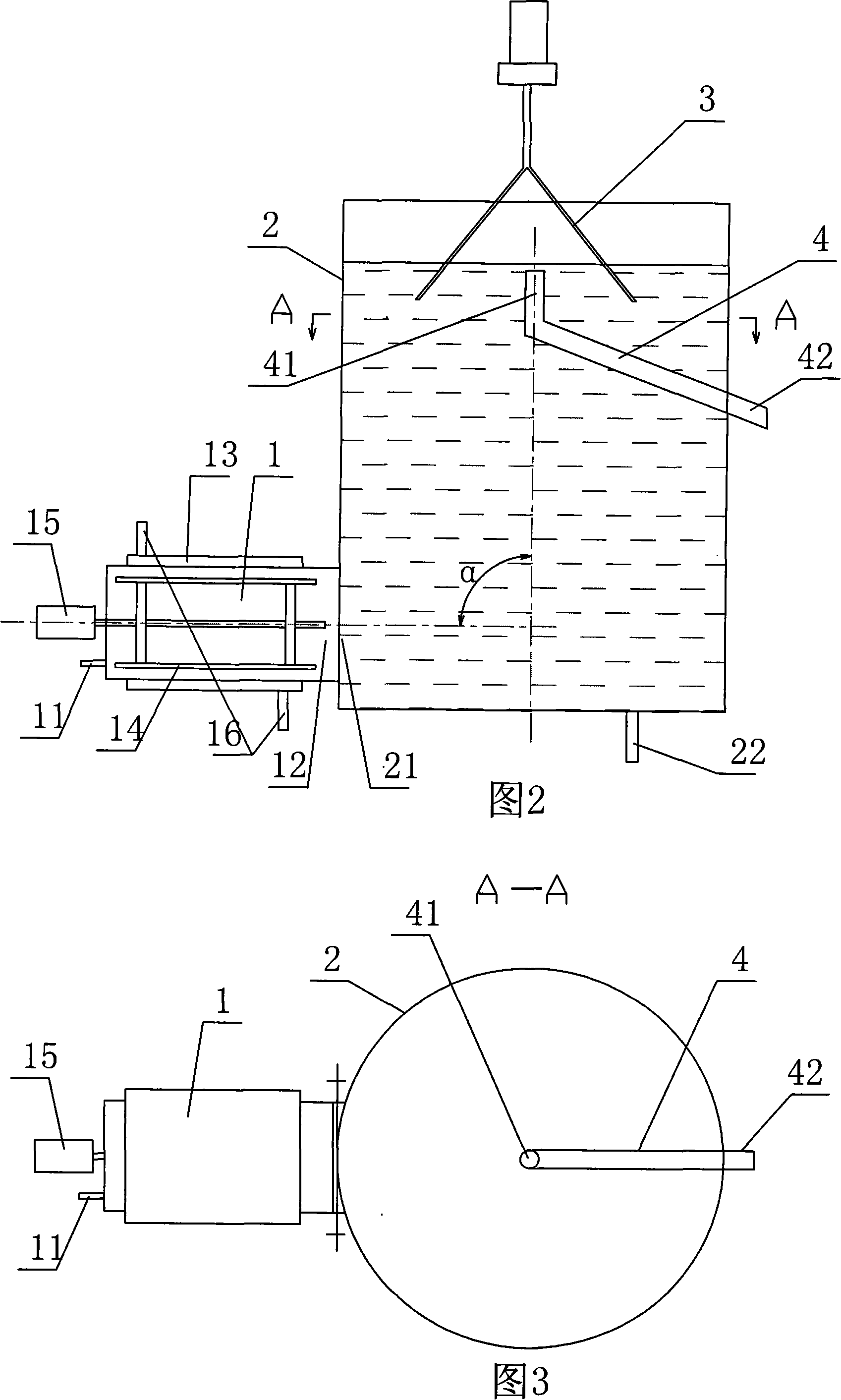

[0031] As shown in Figure 2 and Figure 3, it is a schematic diagram of the structure of Embodiment 2 of the present utility model. The difference between Embodiment 2 and Embodiment 1 is that the bottom of the ice crystal growth tank is provided for connecting with the material outlet 12 of the scraper heat exchanger 1 The material inlet 21, the outer periphery of the heat exchanger is provided with an interlayer 13 for the circulation of the refrigerant, and the inside is provided with a scraper 14 for scraping off ice crystals adhering to the inner wall. The tank wall between the interlayer and the inner cavity of the tank constitutes the heat exchange surface between the refrigerant and the material in the tank. Due to the low temperature of the heat exchange surface, ice crystals can be rapidly formed on the surface of the material in direct contact with the heat exchange surface. The scraper 14 is controlled by the driving device 15 and rotates slowly in the heat exchanger...

Embodiment 3

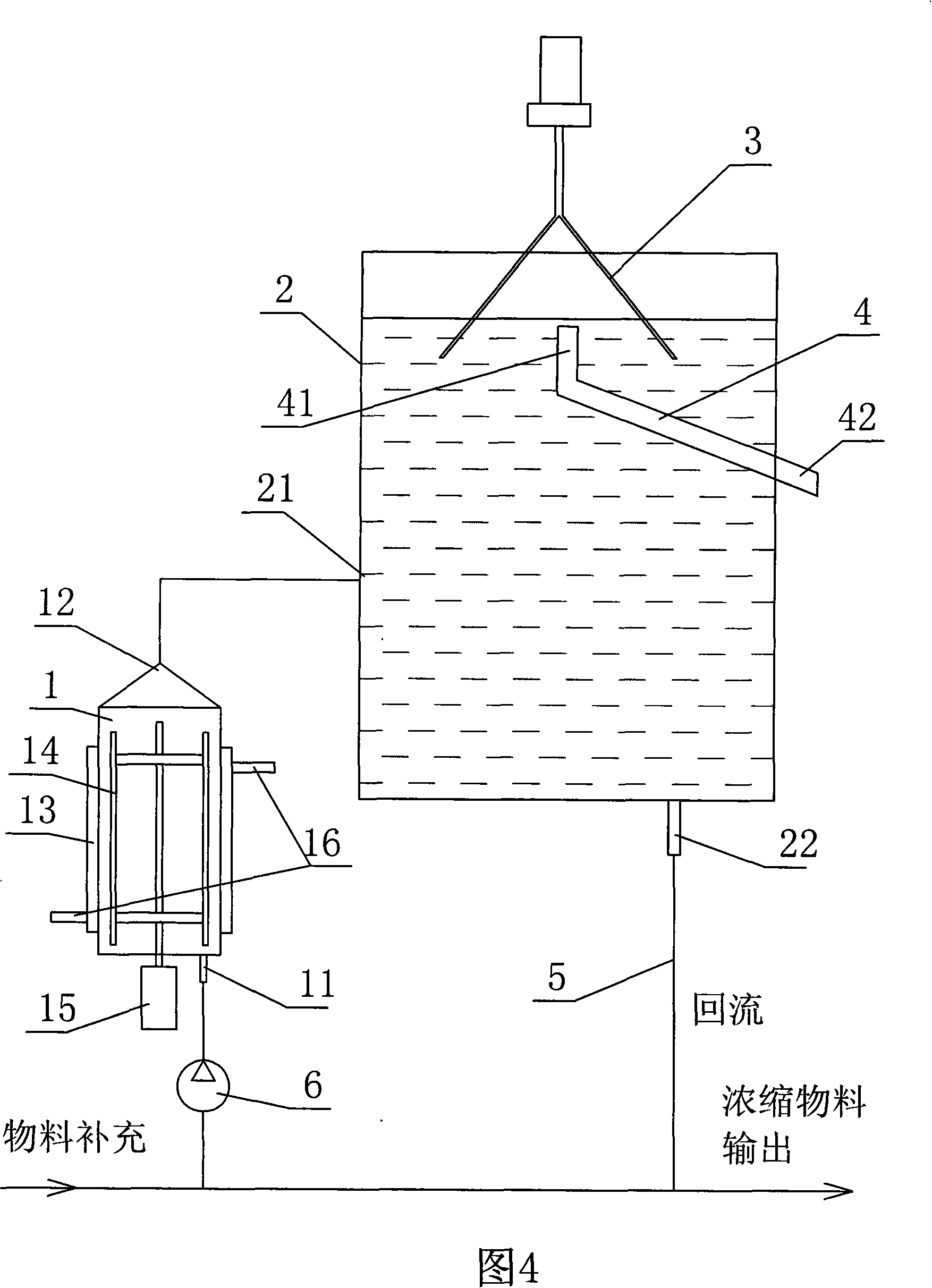

[0035] As shown in Figure 4, it is a schematic diagram of the structure of Embodiment 3 of the present invention. The difference between Embodiment 3 and Embodiment 2 is that: the scraper heat exchanger and the ice crystal growth tank are set independently, and the material outlet of the heat exchanger passes through a pipeline. It is connected with the bottom of the ice crystal growth tank, and the bottom of the ice crystal growth tank is also provided with another return pipe 5 connected to the material inlet of the heat exchanger. Openable and closed pumping device 6 for recrystallization in the heater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com