Start working method of fluidization catalytic reaction device for preparing low carbon olefinic hydrocarbon

A technology of catalytic reaction and low-carbon olefins, applied in the direction of carbon compound catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as pollution, loss of catalyst activity, incomplete combustion of light diesel oil, etc., and improve economic benefits , protect the catalyst and shorten the start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

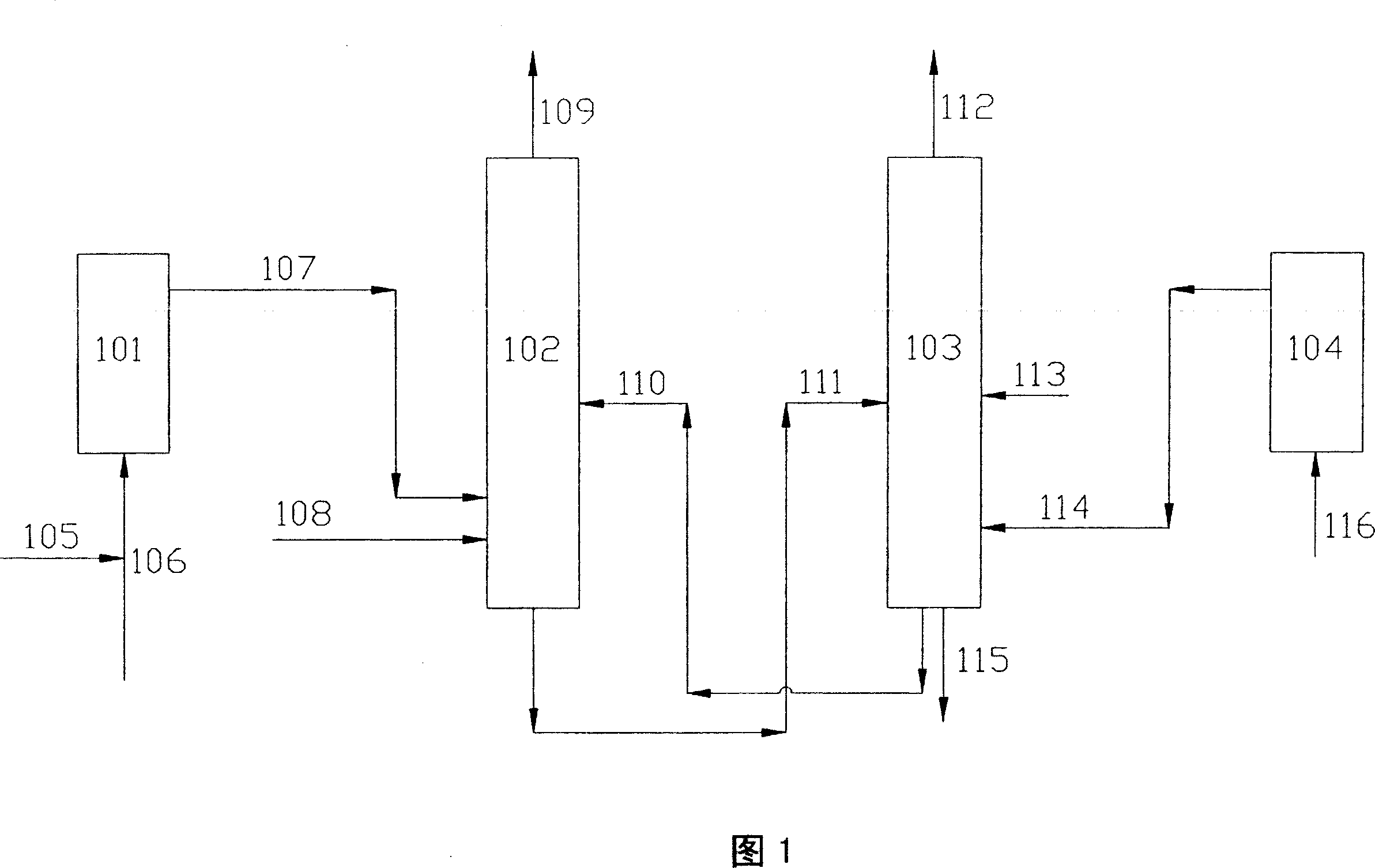

[0024] Fig. 1 is a process schematic diagram of the reaction-regeneration part in this embodiment. 101 is a heater for preheating nitrogen or steam, 102 is a reactor, 103 is a regenerator, 104 is an auxiliary heater for preheating air, 105 is a nitrogen inlet pipeline, 106 is a steam inlet pipeline, and 107 is nitrogen or steam entering the reaction 108 is the pipeline for methanol feed, 109 is the pipeline for the product gas to the cooling system, 110 is the delivery pipeline for the regenerated catalyst to circulate from the regenerator to the reactor, and 111 is the coked catalyst to circulate from the reactor to the regenerator after the reaction Delivery pipeline, 112 is regeneration flue gas discharge pipeline, 113 is delivery pipeline of catalyst from catalyst storage tank to regenerator, 114 is large pipeline of air from auxiliary heater to regenerator, 115 is delivery of catalyst from regenerator back to catalyst storage tank Line, 116 is the air inlet line.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com