Rotating molecular sieve minisize pressure swing adsorption oxygen making device

A pressure swing adsorption oxygen production and molecular sieve technology, which is applied in the fields of pressure swing adsorption oxygen production devices and rotary molecular sieve micro pressure swing adsorption oxygen production devices, can solve the problems of high use cost, small flow rate, and current barrier, etc., to improve exergy Exergy efficiency, weight reduction, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

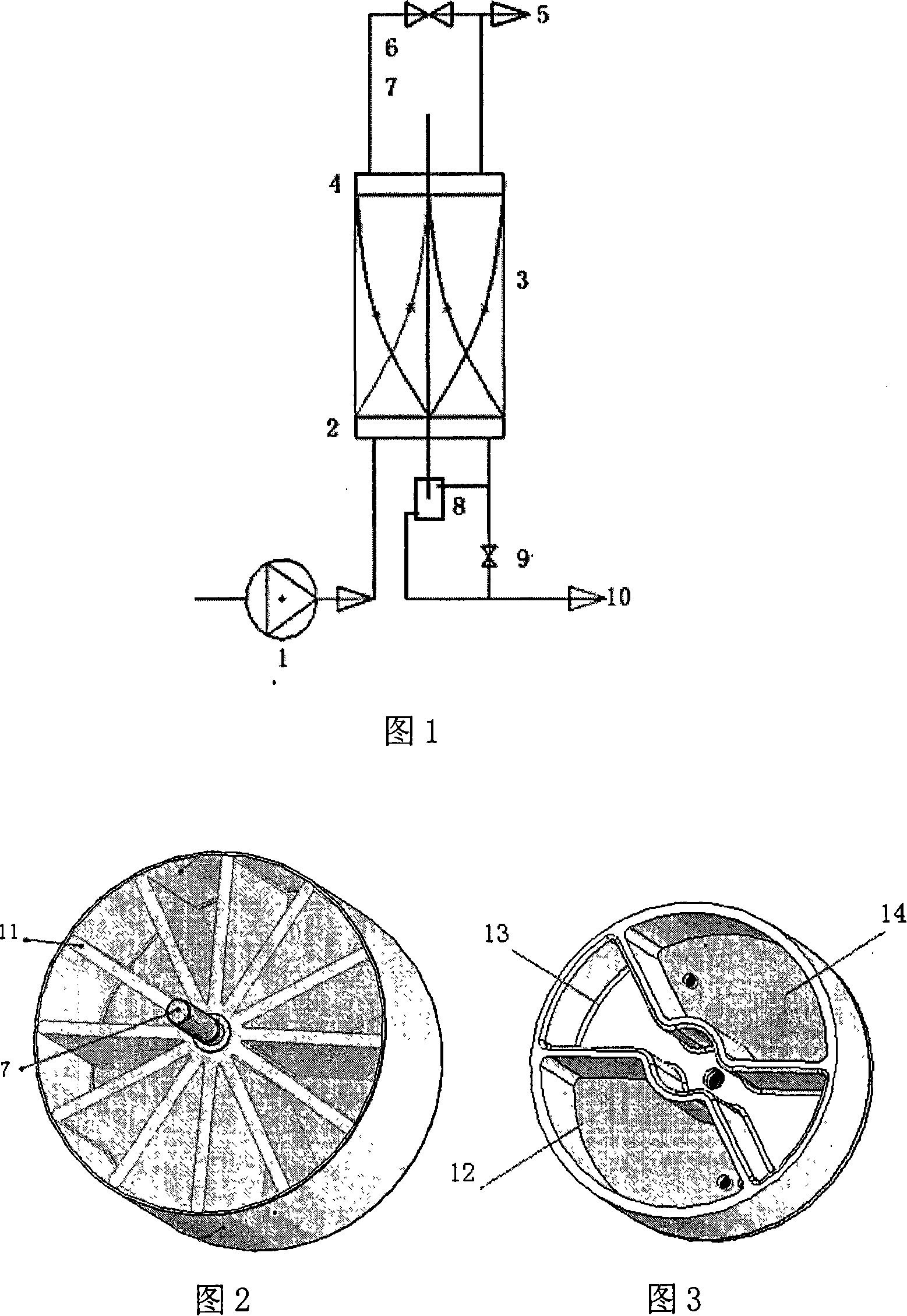

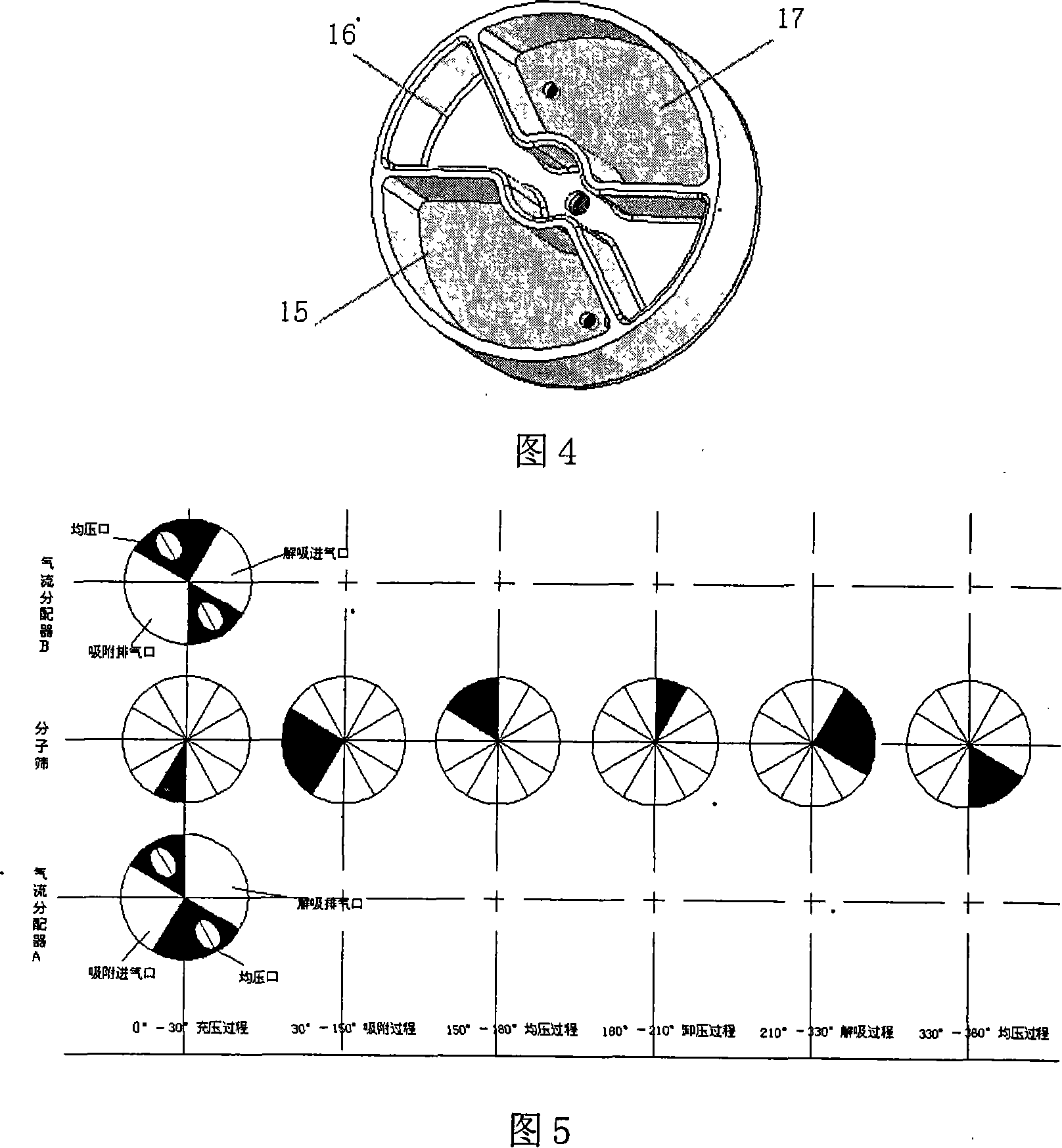

[0047] The structural principle and working principle of the present invention will be further described in detail below with reference to the accompanying drawings.

[0048] 1, 2, 3, 4, the present invention includes a molecular sieve container 3 and a rotating mechanism 8 connected with it, the molecular sieve container 3 includes a rotating shaft 7 arranged in the center thereof and a core 11 uniformly arranged in the molecular sieve container 3, The core 11 divides the molecular sieve container 3 into several molecular sieve channels, the molecular sieve container 3 is connected with the rotating mechanism 8 through the rotating shaft 7, and the two sides of the molecular sieve container 3 are respectively provided with an air inlet cover 2 and an exhaust gas which communicate with it. Cover 4, intake cover 2 includes an independent intake cover intake buffer chamber 12 with an intake port, an intake cover pressure equalizing chamber 13 and an intake cover exhaust buffer ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com