Fuel batter with proton exchange film electric pole catalyze layer and producing thereof

A technology of fuel cell electrodes and proton exchange membranes, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor catalyst contact and low utilization rate of catalysts, and achieve the effect of improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

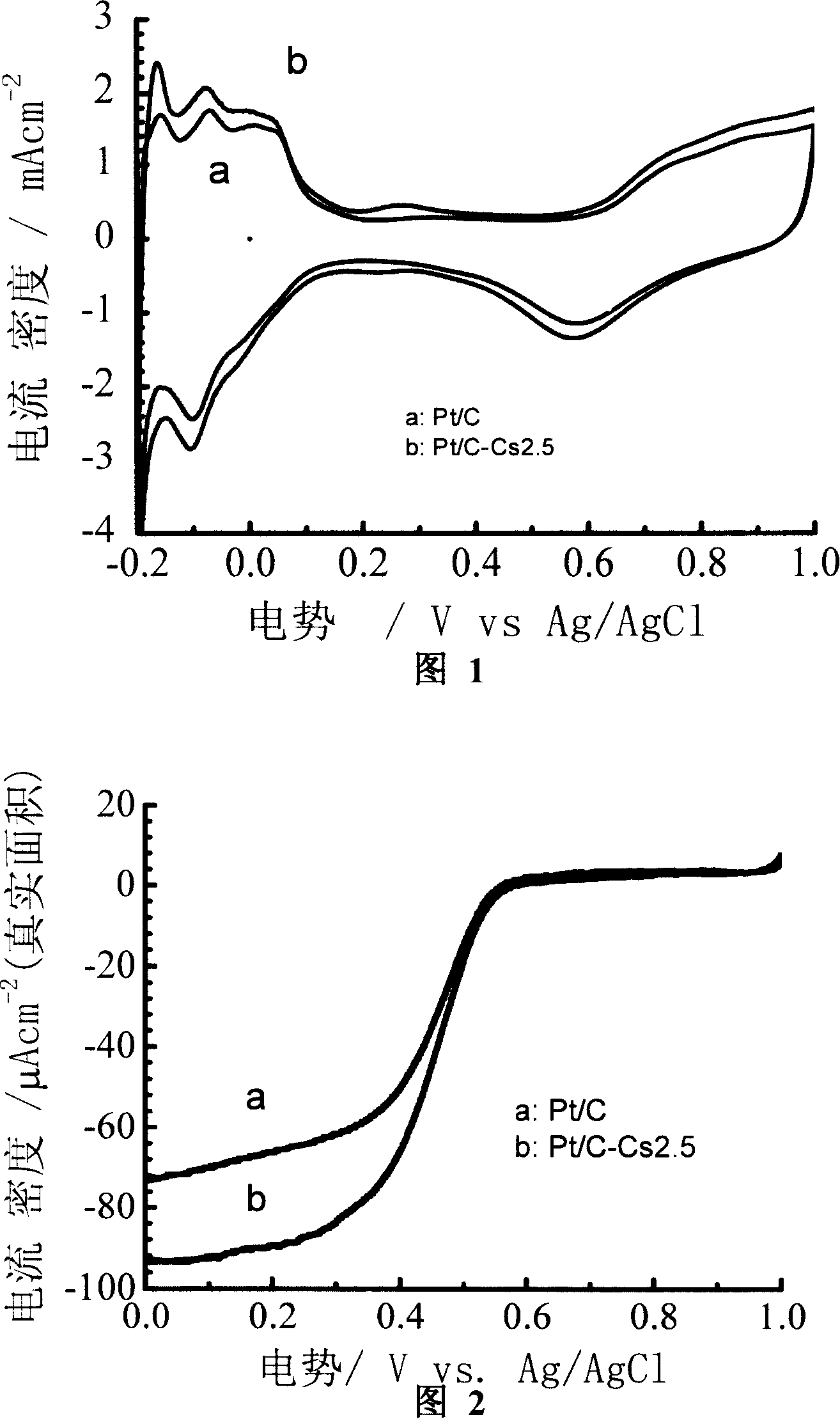

[0039] 3mg of Pt / C catalyst (46.2wt%Pt, Japan Tanaka company) and a certain amount of cesium hydrogen phosphomolybdate (Cs 2.5 h 0.5 PMo 12 o 40 , referred to as Cs2.5), 0.5ml of isopropanol solution containing 0.5% Nafion in mass concentration, mixed with 2ml of isopropanol, and ultrasonically stirred at room temperature, wherein Pt / C and Cs 2.5 h 0.5 PMo 12 o 40 The mass ratio is 4:1. After stirring for 1 hour, take 10 microliters of the suspension and apply it to a glassy carbon electrode (the effective area is 0.1256cm 2 ) was dried at room temperature to obtain a working electrode. The platinum mesh was used as the counter electrode, the Ag / AgCl (saturated potassium chloride) electrode was used as the reference electrode, and the 0.5M sulfuric acid solution was used as the electrolyte to measure the cyclic voltammetry curve of the working electrode, as shown in Figure 1. The scan rate is 50mV / s. By calculating the area of the hydrogen desorption peak of Pt, 210...

Embodiment 2

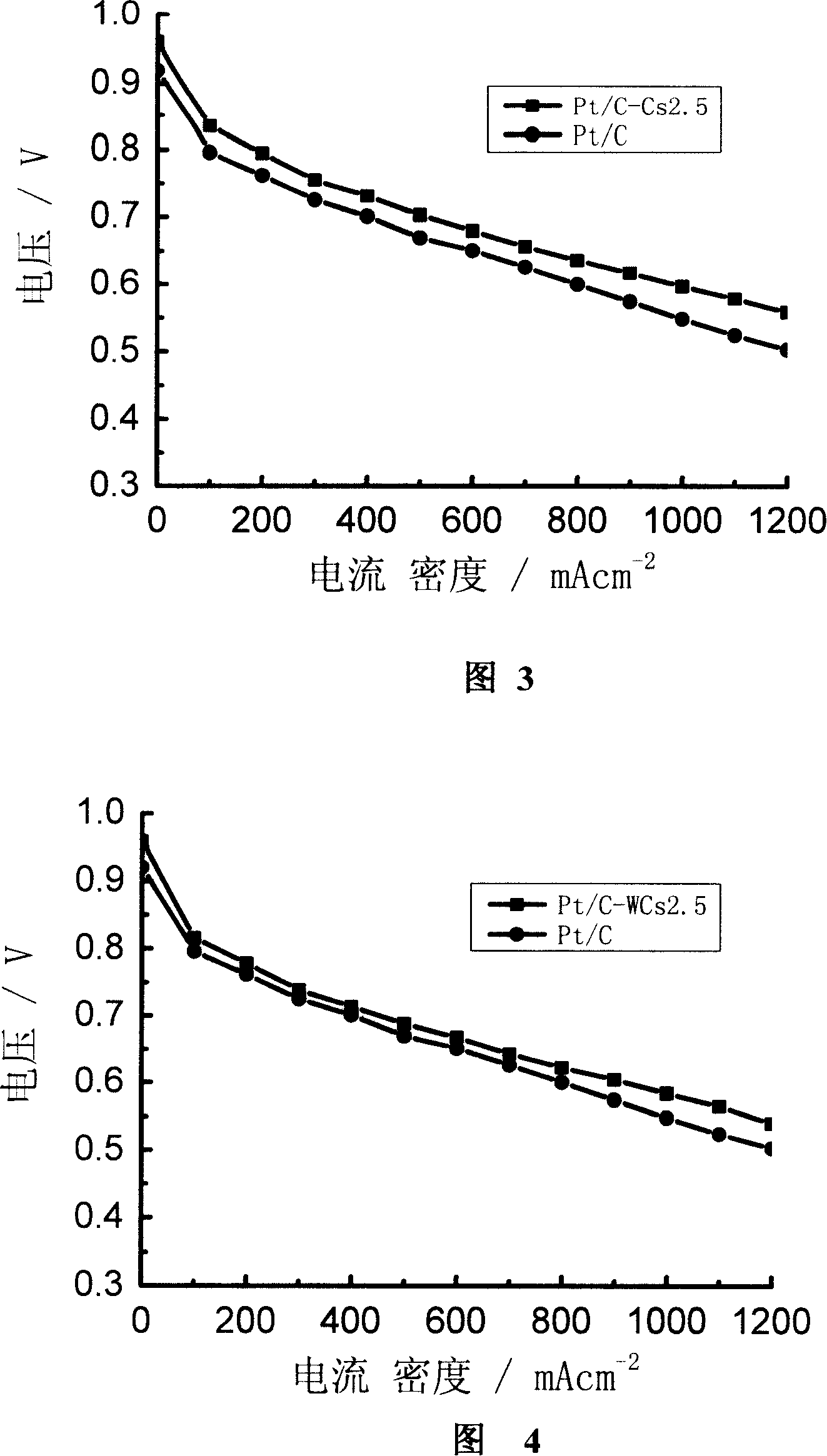

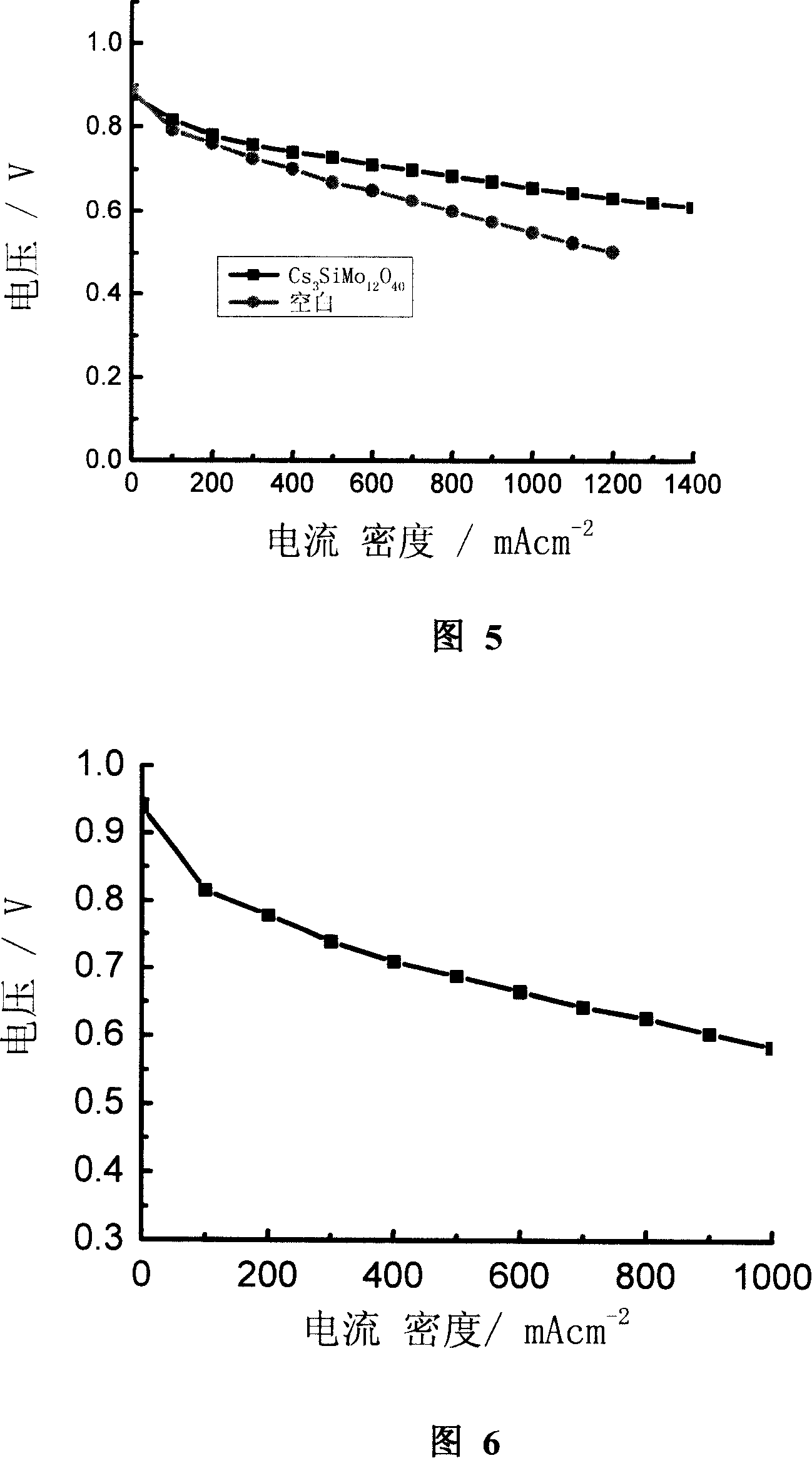

[0044] 10mg catalyst Pt / C (46.2wt%Pt, Japan Tanaka company) and a certain amount of Nafion, cesium hydrogen phosphomolybdate (Cs 2.5 h 0.5 PMo 12 o 40 , referred to as Cs2.5) and isopropanol are mixed to make a uniform suspension under ultrasonic vibration, wherein the mass ratio of Pt / C catalyst, organic proton conductor Nafion, heteropoly acid salt Cs2.5, and isopropanol is 10:2.5:2.5:500. Then, spray this suspension on Nafion The two sides of NRE-212 are used as the catalytic layer, dried in air at 80°C for 2 hours, and then hot-pressed with the hydrophobically treated carbon paper diffusion layer at 140°C to obtain a three-in-one membrane electrode. The amount of Pt used in the catalytic layer is 0.07mg / cm 2 . Add the anode and cathode flow field plates on both sides of the three-in-one membrane electrode, the current collector plate and the end plate to form a single cell. The effective area of the electrode is about 5cm 2 . The cathode and anode are respecti...

Embodiment 3

[0048] 10mg catalyst Pt / C (46.2wt%Pt, Japan Tanaka company) and a certain amount of Nafion, cesium hydrogen phosphotungstate (Cs 2.5 h 0.5 PW 12 o 40 .abbreviated as WCs2.5) and isopropanol, and made into a homogeneous suspension under ultrasonic vibration, wherein the mass ratio of Pt / C catalyst, organic proton conductor Nafion, heteropoly acid salt WCs2.5, and isopropanol is 5:5:5:500. Then, apply this suspension on Nafion The two sides of NRE-212 are used as the catalytic layer, dried at 130°C under the protection of nitrogen for 0.5 hours, and then hot-pressed with the hydrophobically treated carbon paper diffusion layer at 140°C to obtain a three-in-one membrane electrode. The amount of Pt used in the catalytic layer is 0.07mg / cm 2 . The evaluation battery was assembled according to the method of Example 2, and the V-i curve of the membrane electrode was measured under the same conditions, as shown in FIG. 4 .

[0049] Comparative example is the same as embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com