Mesoporous polydivinylbenzene material with hypersorption characteristic and synthesis method thereof

A technology of polydivinylbenzene and divinylbenzene, which is applied in the field of physical chemistry, can solve the problems of limited application of mesoporous polymers, no swelling property, high synthesis cost, and achieves simple and easy synthesis process and synthesis cost. The effect of low, strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Mesoporous polydivinylbenzene PDVB-THF-0 synthesized in tetrahydrofuran system.

[0026] Dissolve 2g of divinylbenzene (DVB) monomer and 0.05g of azobisisobutyronitrile (AIBN) in 20mL of tetrahydrofuran, and after stirring for 4 hours, transfer the above solution to a reaction kettle and place it in an oven at 100°C for 48 Hour. The reactor was taken out to volatilize tetrahydrofuran to obtain mesoporous polydivinylbenzene PDVB-THF-0.

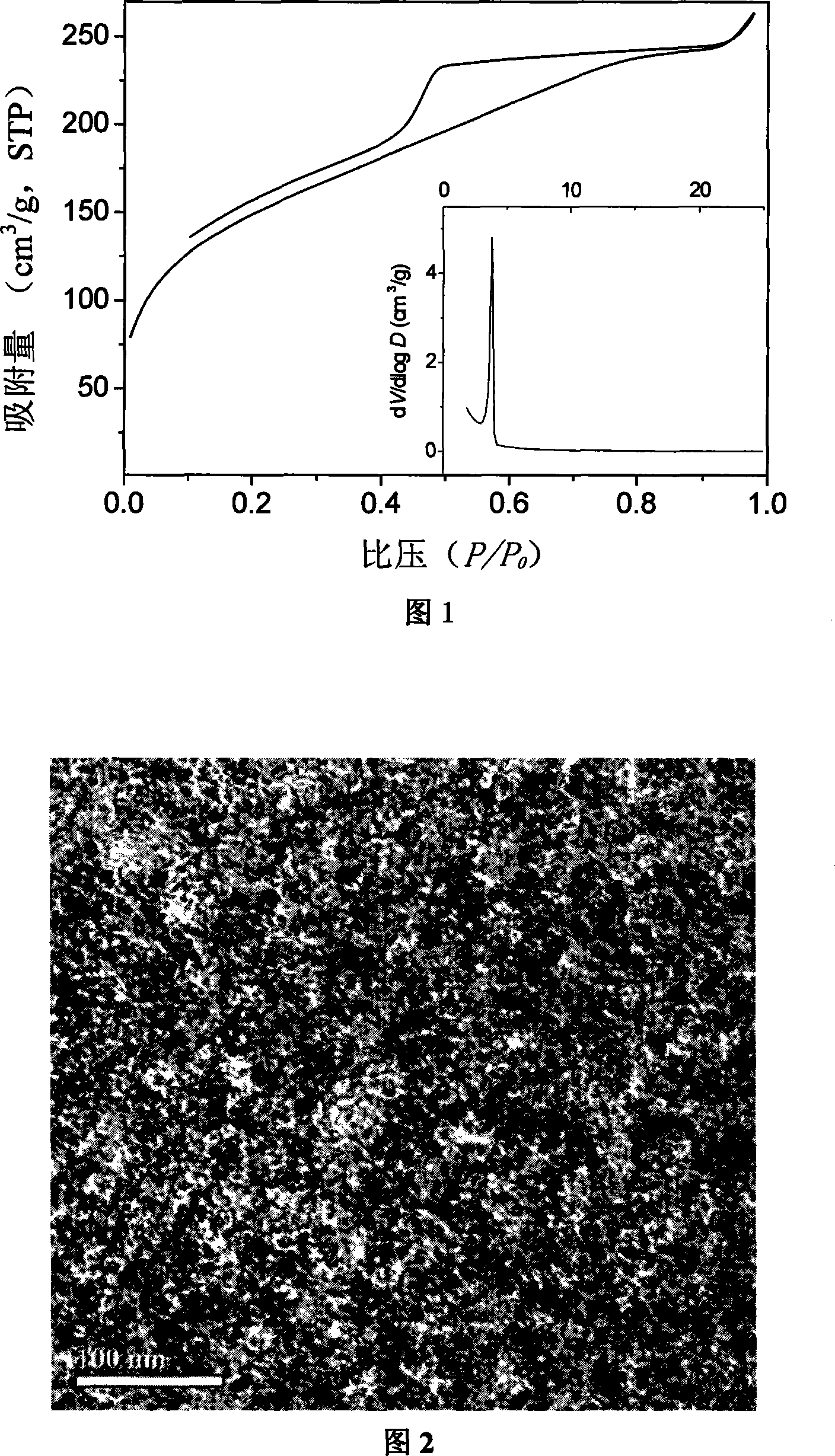

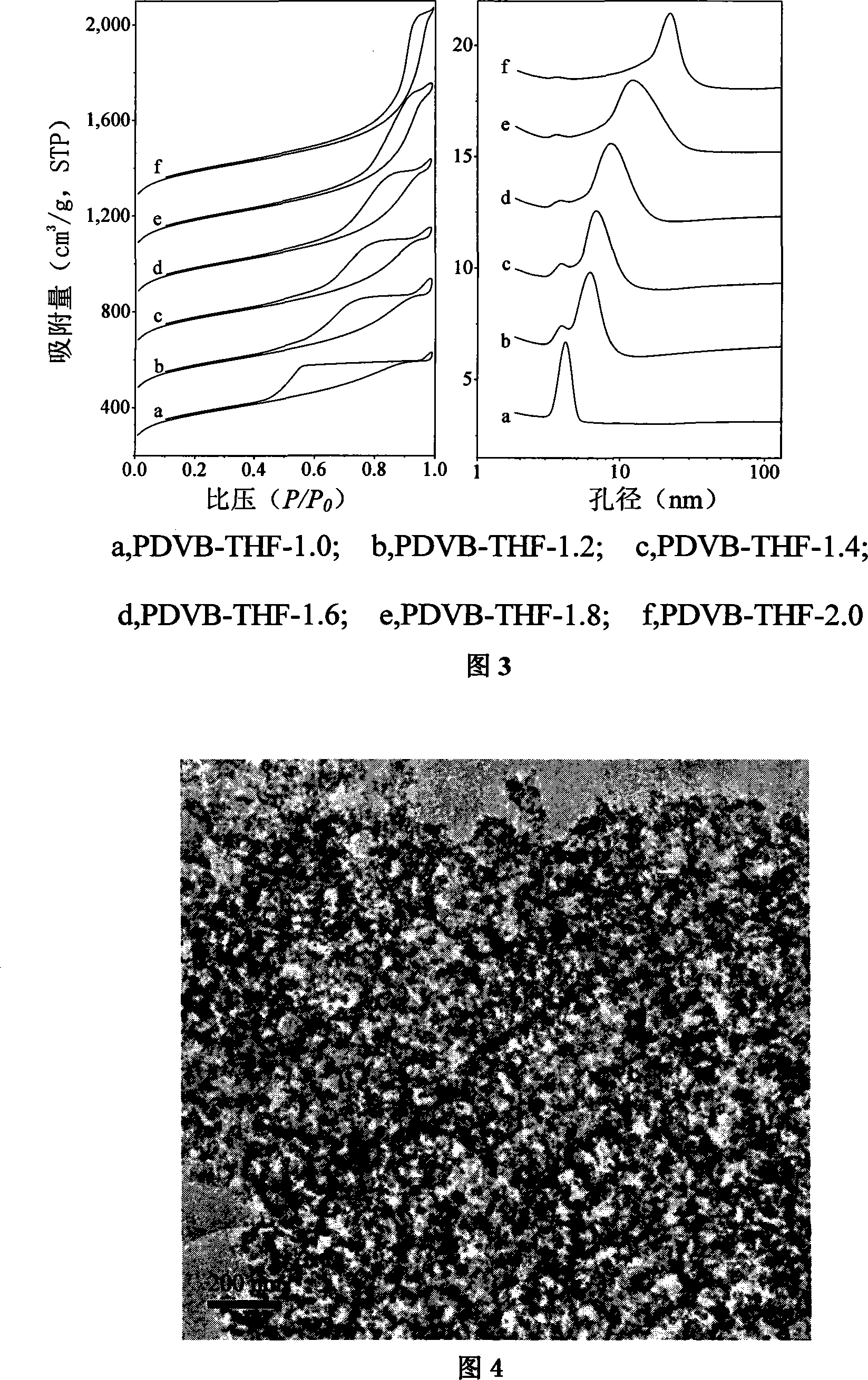

[0027] The results of nitrogen adsorption experiments are shown in Fig. 1. The type IV adsorption isotherm given by sample PDVB-THF-0 indicates that the sample has a mesoporous structure and a relatively narrow pore distribution (~3.9nm). Figure 2 is a transmission electron microscope (TEM) photo of the sample PDVB-THF-0. The results further confirm the nitrogen adsorption results. From Figure 2, we can clearly see the existence of abundant mesopores. The BET specific surface area of sample PDVB-THF-0 is 557m 2 / g.

[0...

Embodiment 2

[0030] Example 2: Synthesis of mesoporous polydivinylbenzene PDVB-THF-x in a composite system of tetrahydrofuran and water.

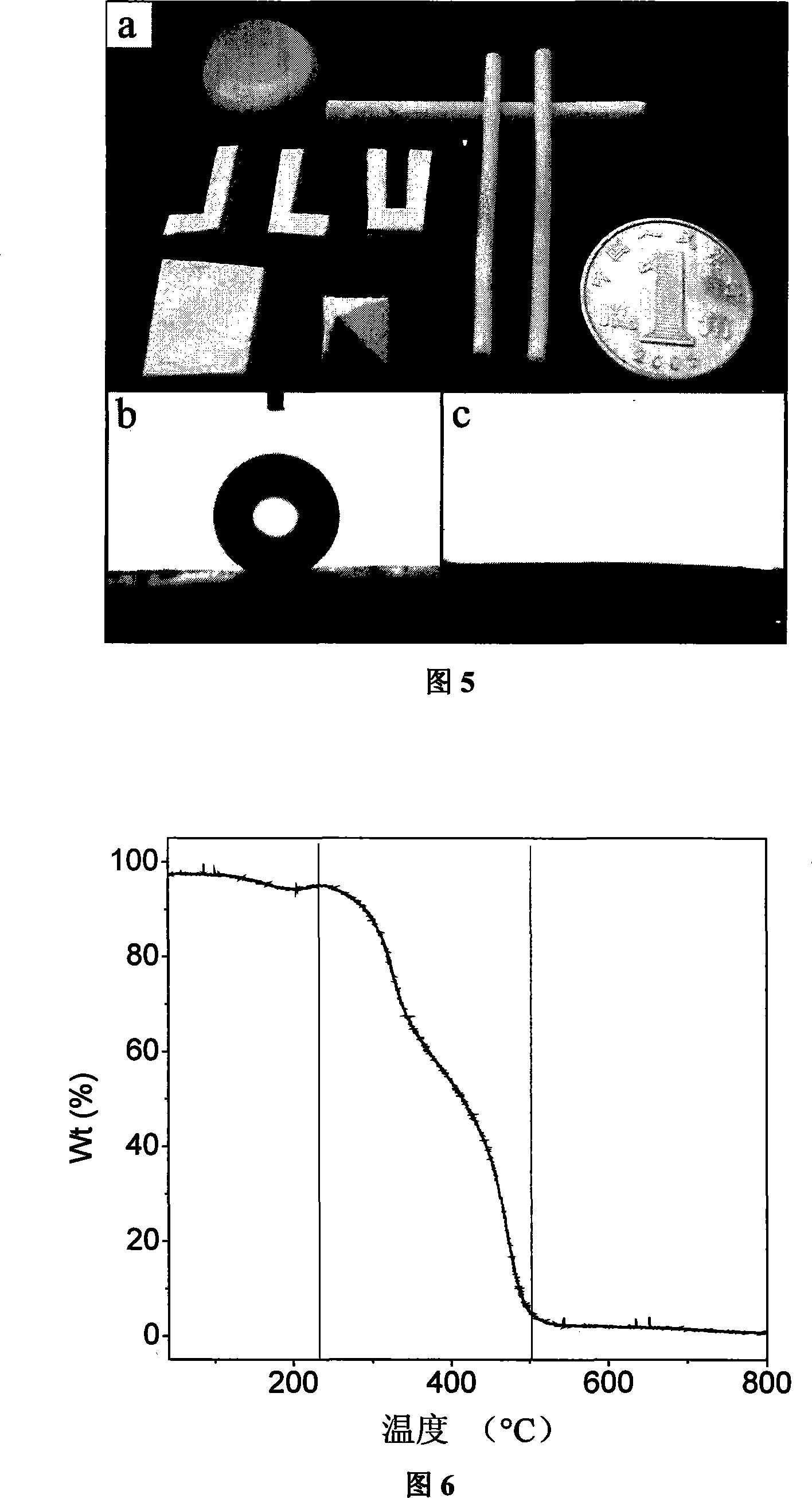

[0031] Dissolve 2 g of divinylbenzene (DVB) monomer and 0.05 g of azobisisobutyronitrile (AIBN) in 20 mL of tetrahydrofuran, then add x mL of water, where x=1.0, 1.2, 1.4, 1.6, 1.8, 2.0, and stir After 4 hours, the above solution was transferred to a reaction kettle and placed at 100° C. for 48 hours. The reactor was taken out to volatilize tetrahydrofuran to obtain mesoporous polydivinylbenzene PDVB-THF-x.

[0032] In this example, the amount of water is not limited to 1-2 mL, but can be adjusted from 0 to 10 mL, and 1-2 mL is selected for convenience of discussion. When it is less than 1mL, the regulating effect of the pore size is not obvious. A further increase in pore size can be achieved when greater than 2 mL. The sample of PDVB-THF-10 also has a higher specific surface area of 650m 2 / g. But the pore distribution is relatively broad. It ...

Embodiment 3

[0035] Example 3: Synthesis of mesoporous polydivinylbenzene PDVB-acetone in acetone system.

[0036] Replace tetrahydrofuran in Example 1 with 20 mL of acetone, and the rest of the steps are the same as in Example 1. Referring to Figure 9, the nitrogen adsorption isotherm shows that the sample has the characteristics of a composite pore structure of micropores and mesoporous pores. From the results of BJH pore distribution and DFT pore distribution, it can be seen that the sample has both mesopores of ~3.9nm and pore diameters of ~1.1nm. microporous. BET specific surface area can reach 416m 2 / g, of which micropore 173m 2 / g, mesopore 242m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mesoporous | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com