Skid-mounted type fuel oil supercritical pressure direct-flow gas injection boiler

A steam injection boiler, supercritical technology, applied in steam boilers, water-tube steam boilers, steam generation and other directions, can solve the problems of low load bearing capacity, a large number of formed elbows, and no free expansion, and achieve strong load bearing capacity. , low center of gravity, reducing the effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

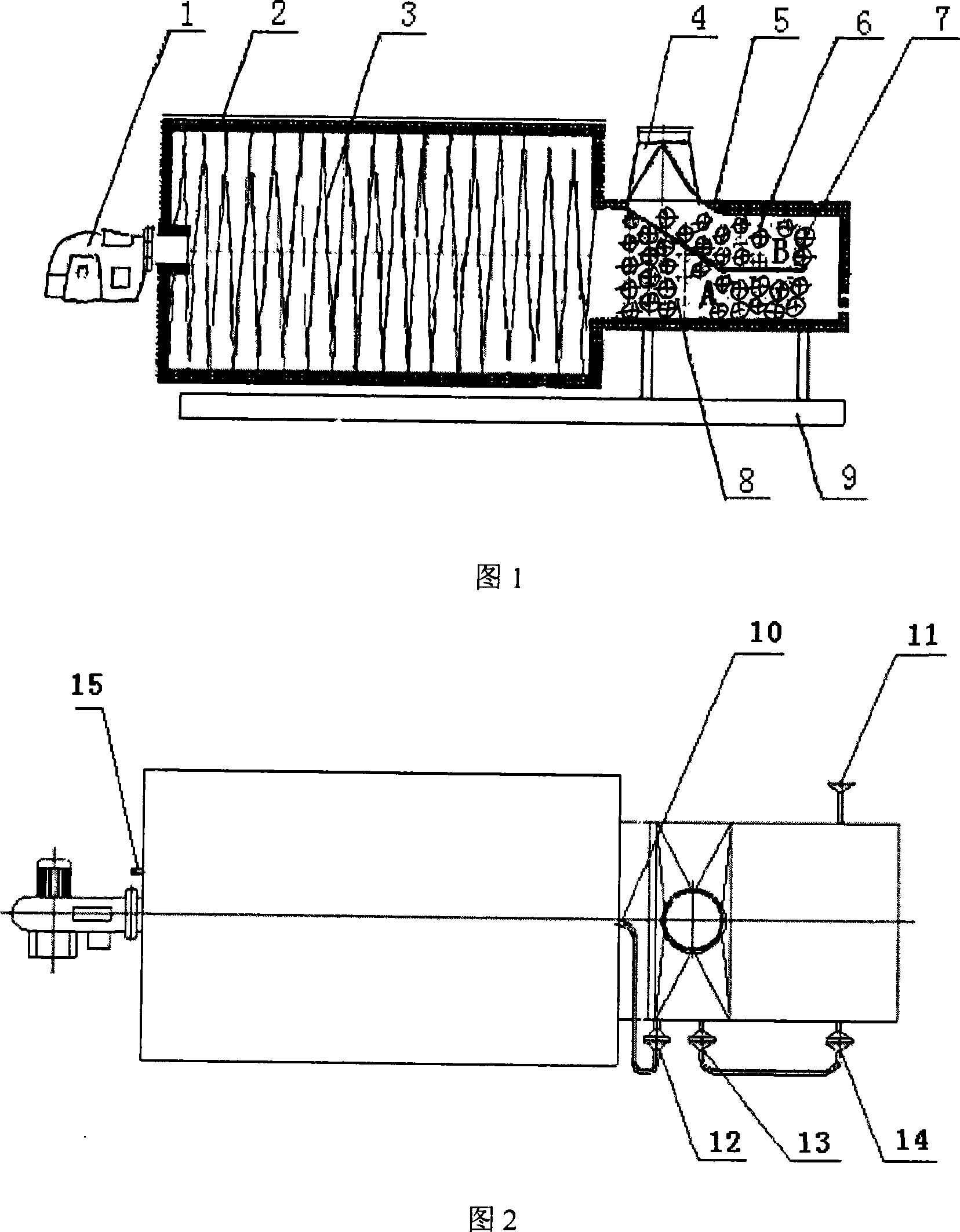

[0051] The skid-mounted fuel oil supercritical pressure once-through steam injection boiler of the present invention further solves the flow pulsation of the working medium in the heating tube of the steam generator, the deterioration of the heat transfer of the working medium, salt accumulation in the tube, water quality and water treatment in the process of design and realization system and other issues. The designed skid-mounted fuel oil supercritical pressure once-through steam injection boiler should be as compact as possible, not only to meet the changing needs of the oil production site, but also to facilitate transportation.

[0052] Referring to the accompanying drawings, the skid-mounted fuel oil supercritical pressure once-through steam injection boiler of the present invention includes the heating surface of the boiler body, and the heating surface of the boiler body is divided into a radiation heating surface 3, a first convection heating surface 8 and a second Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com