Positive electrode material for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

A non-aqueous electrolyte and positive electrode material technology, which is applied in the field of positive electrode materials for non-aqueous electrolyte secondary batteries and non-aqueous electrolyte secondary batteries, can solve the problem of LiCoO2 structural deterioration of the positive electrode surface electrolyte, discharge capacity charge-discharge cycle characteristics degradation, no Sufficient and other issues, to achieve good charge-discharge cycle characteristics, good thermal stability and high discharge capacity, high thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Mixing Li in a stone grinder mortar 2 CO 3 and Co 3 o 4 , making the molar ratio of Li:Co 1:1. Then it was heat-treated at 850°C for 24 hours in an air atmosphere, and then it was pulverized to obtain LiCoO with an average particle diameter of about 14 μm. 2 .

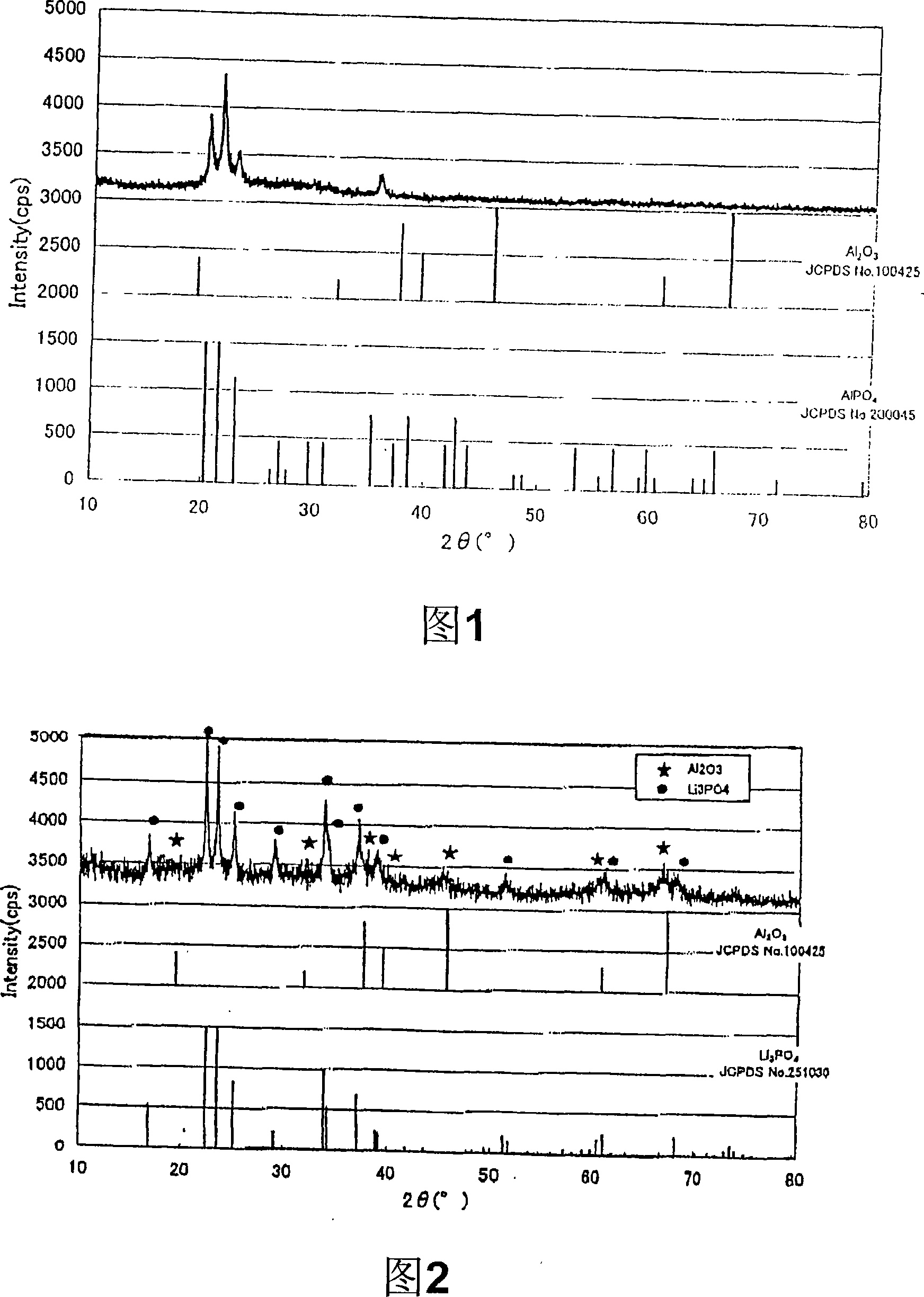

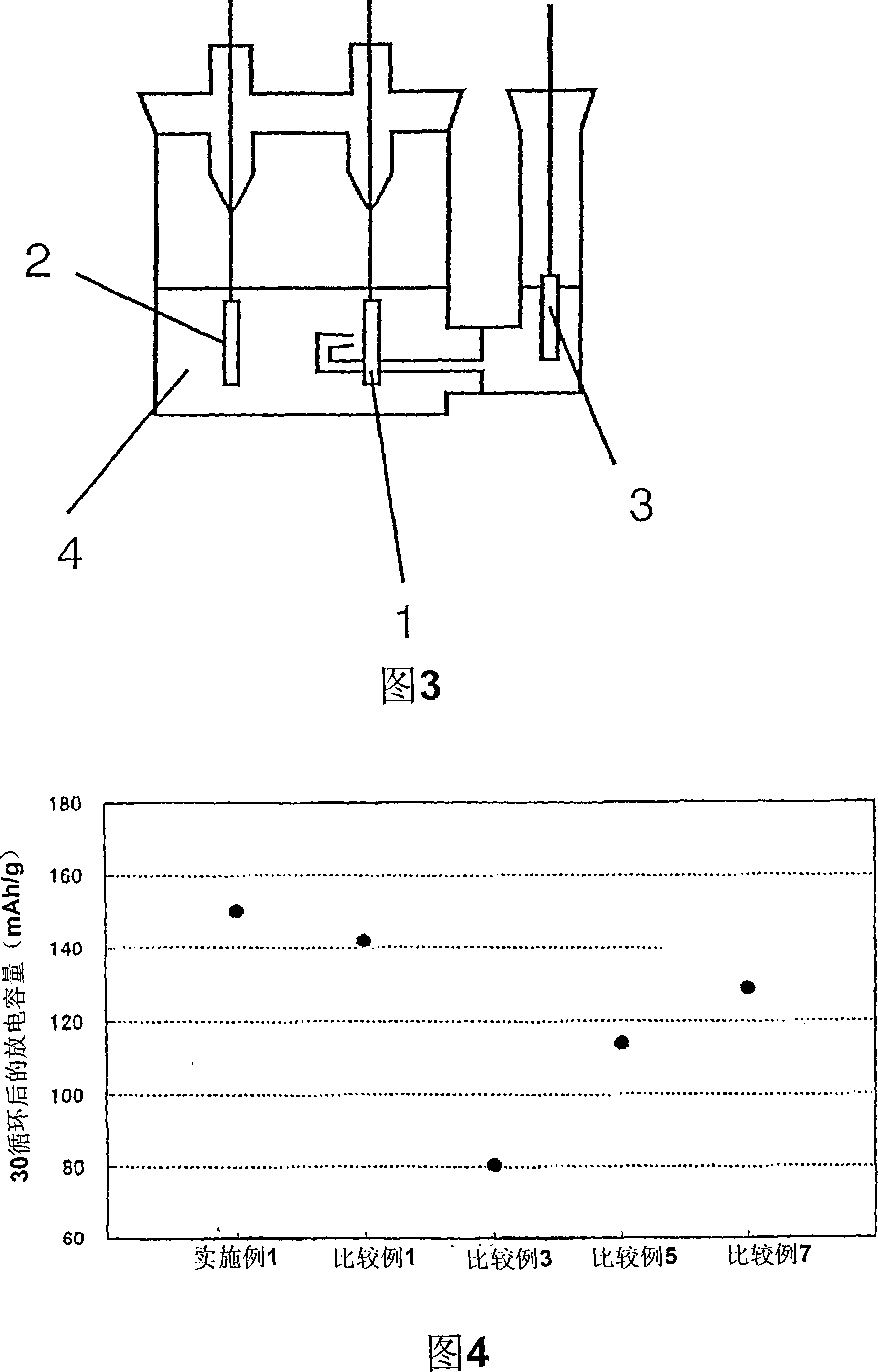

[0072] 1.32g (0.01mol) of (NH 4 ) 2 HPO 4 Dissolve in 20ml of water and add NH to it 3 (aq) Make pH 10 or more. Add 25g of LiCoO produced above to this solution 2 , after that, slowly add 3.75g (0.01mol) Al(NO 3 ) 3 The solution. The solution formed by the above method was stirred for 10 minutes, after that, centrifuged at 2000rpm, after removing the clear part above, stirred in the solution formed after dissolving 0.69g (0.03mol) LiOH in 100ml water, and again with Centrifuge at 2000rpm to remove the above clarified part. After that, it was fired at 400° C. for 5 hours in air to obtain the positive electrode material of Example 1.

[0073] [making of positive electrode]

[0074] Dissolve polyvin...

Embodiment 2

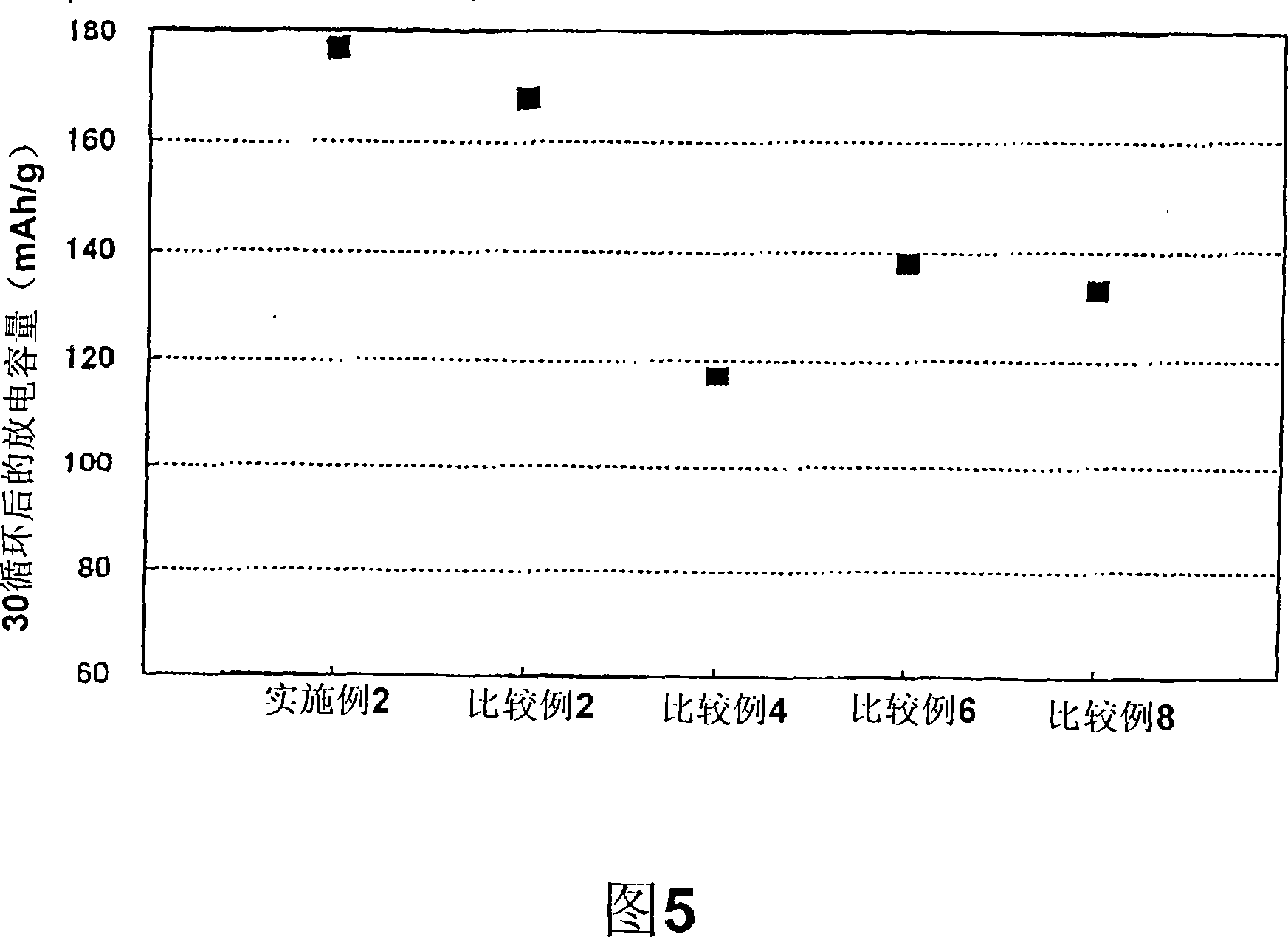

[0089]The positive electrode active material was obtained in the same manner as in Example 1, and the positive electrode was produced. Then, in the three-electrode cup battery, the following evaluation methods were used for evaluation, and the electrochemical characteristics, thermal stability.

[0090] (Charge termination potential is 4.5V (vs.Li / Li + ) evaluation method of electrochemical characteristics)

[0091] [Evaluation of initial charge and discharge characteristics]

[0092] At room temperature, at 0.75mA / cm 2 (about 0.3C) constant current charges the fabricated three-electrode cup battery until the potential of the working electrode reaches 4.5V (vs.Li / Li + ), moreover, at 0.25mA / cm 2 (about 0.1C) constant current to charge it until the potential reaches 4.5V (vs.Li / Li + ), after that, at 0.75mA / cm 2 (about 0.3C) constant current discharges it until the potential reaches 2.75V (vs.Li / Li + ), thereby evaluating the initial charge-discharge characteristics.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com