Method for preparing polymerized boron silazane precursor

A technology for polyborosilazane and precursors is applied in the field of preparation of polyborosilazane precursors, which can solve the problems of cumbersome and complicated processes, unfavorable popularization and application, and high cost, and achieves simple reaction process, low cost and reliable source. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

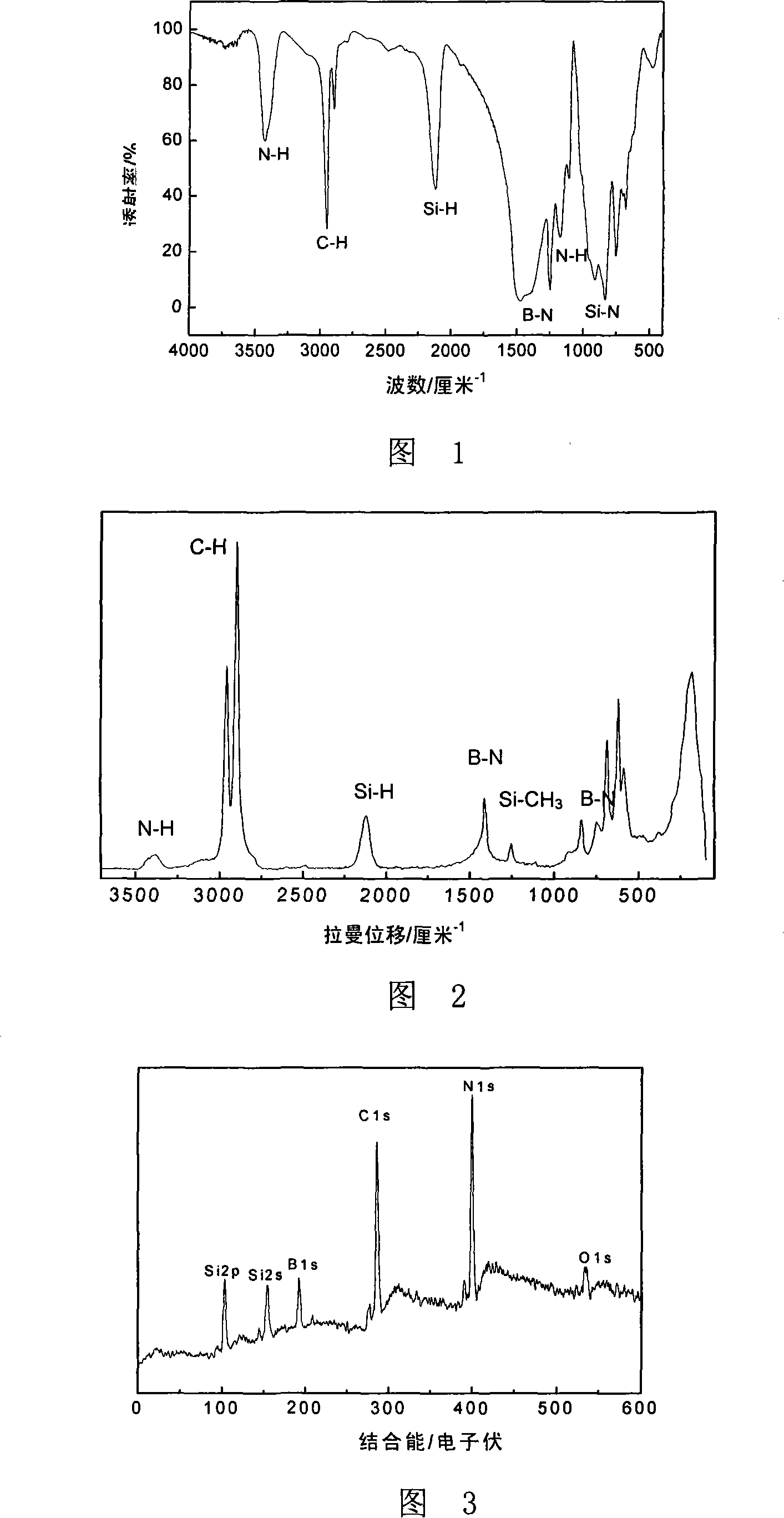

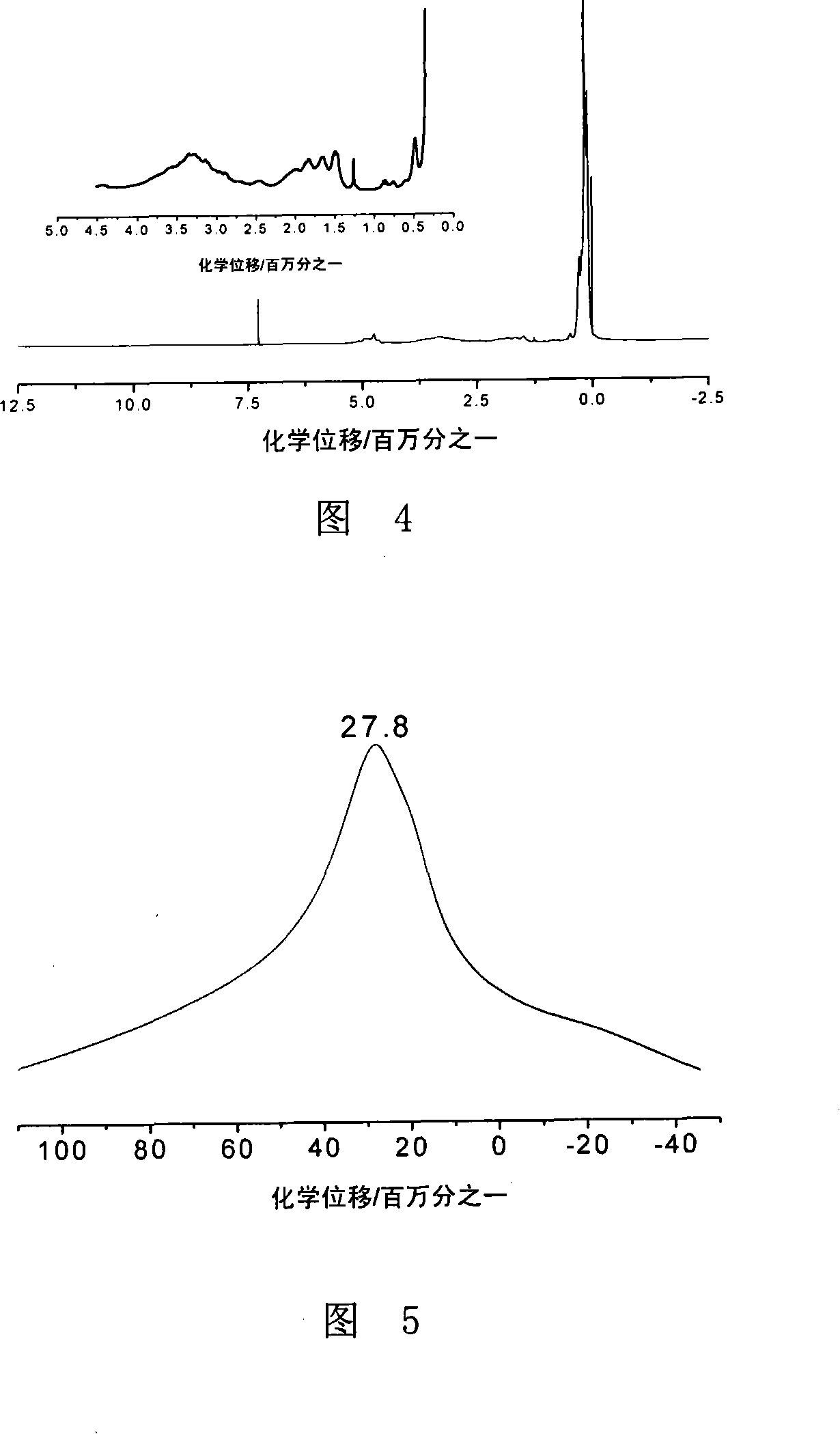

Embodiment 1

[0033] (1) The 250ml three-neck flask with the electric stirring device in the reactor was repeatedly vacuumized and filled with dry nitrogen three times to remove the air and moisture therein, and then the reactor was pre-cooled to minus 10 degrees;

[0034] (2) Take 0.3mol (34.5g) of methylhydrogendichlorosilane and 0.15mol (17.6g) of boron trichloride into a three-necked flask protected by dry nitrogen with a syringe. The ammonia gas is put into the reaction system, and the system heats up rapidly, and produces a large amount of precipitation; Filter; (4) Place the filtrate obtained in step (3) in a reactor with a condenser tube, a cracking column, and a reflux device, and under the protection of dry nitrogen, slowly heat to carry out cothermal polycondensation, and the reactor temperature is 320°C , the temperature of the pyrolysis column was 450°C, and the temperature was kept for 3 hours; (5) The temperature of the system was lowered to 260°C, and the vacuum distillation...

Embodiment 2

[0041] (1) Same as Example 1; (2) Get 0.3mol (30.3g) of dichlorosilane and 0.3mol (29.0g) of methyl boron dichloride with a syringe and inject them into a three-necked flask protected by dry nitrogen successively, while stirring , while feeding ammonia with a purity of 99.999% into the reaction system, the system heats up rapidly and produces a large amount of precipitation; when the temperature no longer rises, stop the feeding of ammonia; (3) when the temperature of the system drops to room temperature , the system product is filtered in a nitrogen bag; (4) the filtrate obtained in step (3) is placed in a reactor with a condenser tube, a cracking column, and a reflux device, and slowly heated for co-heating under the protection of dry nitrogen Polycondensation, the temperature of the reactor is 270°C, the temperature of the cracking column is 420°C, and the temperature is kept for 2 hours; (5) the temperature of the system is lowered to 200°C, and the vacuum distillation is c...

Embodiment 3

[0043] (1) Same as Example 1; (2) Get 0.3mol (38.7g) of dimethyl dichlorosilane with a syringe, and inject 0.2mol (16.5g) of dichloroborohydroane into a three-necked flask protected by dry nitrogen, While stirring, feed methylamine with a purity of 99.999% into the reaction system, the system heats up rapidly and produces a large amount of precipitation, when the temperature no longer rises, stop the feed of methylamine; (3) until the temperature of the system drops to At room temperature, the system product is filtered in a nitrogen bag; (4) the filtrate obtained in step (3) is placed in a reactor with a condenser tube, a cracking column, and a reflux device, and slowly heated under the protection of dry nitrogen Thermal polycondensation, the temperature of the reactor is 270°C, the temperature of the cracking column is 440°C, and the temperature is kept for 2 hours; (5) The temperature of the system is reduced to 300°C, and the vacuum distillation is carried out for 30 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com