Even compact and transparent laminated double-metal hydroxide film and preparation method thereof

A layered bimetallic and hydroxide technology, which is applied in chemical instruments and methods, iron compounds, nickel compounds, etc., can solve the problems that hinder the application and development of LDHs materials, deviceization, and the difficulty of preparing LDHs into thin films, so as to achieve easy operation , Simple equipment, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step A: 1.1604g (0.004mol) of solid Ni(NO 3 ) 2 .6H 2 O and 0.7503g (0.002mol) of solid Al(NO 3 ) 3 .9H 2 O dissolved in 20ml of deCO 2 in the water.

[0024] Step B: Measure 0.54ml of concentrated ammonia water with a mass percentage concentration of 28%, and dilute to 20ml to obtain dilute ammonia water with a mass percentage concentration of 0.68%.

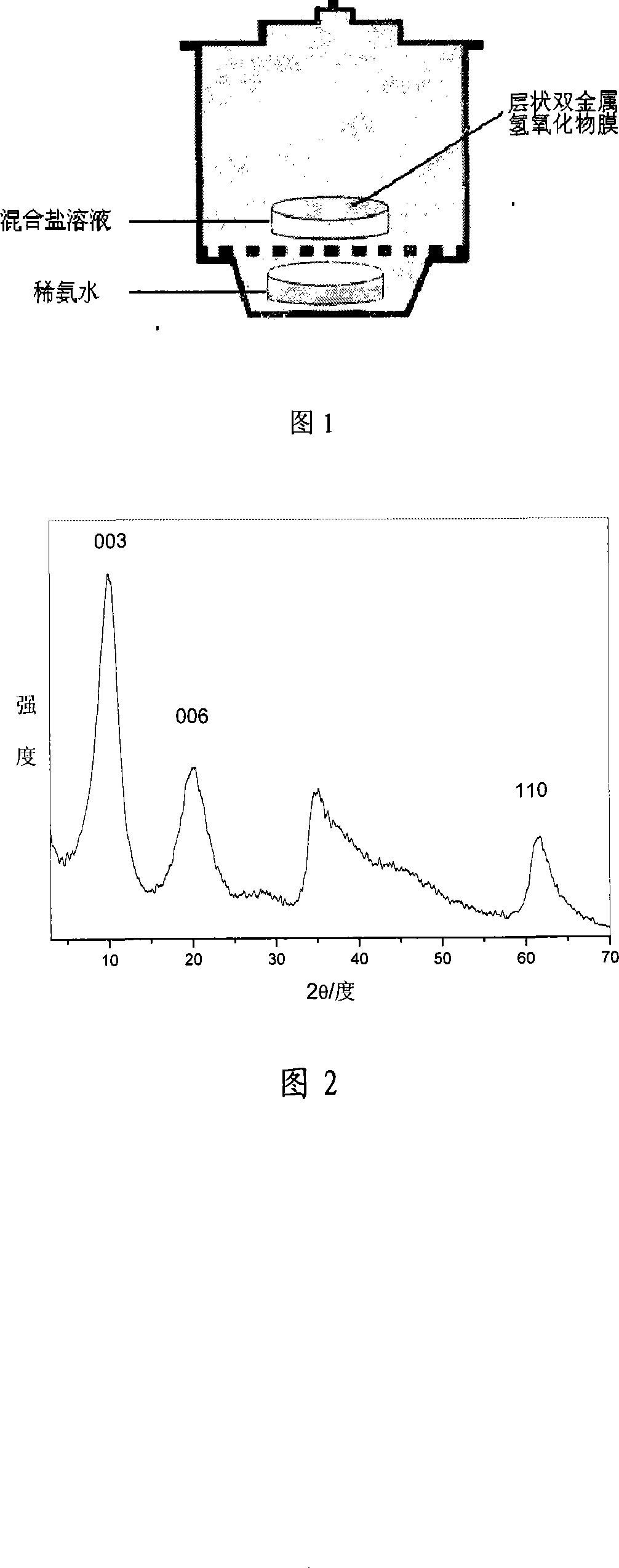

[0025] Step C: Put the mixed salt and lye in different petri dishes, react in a sealed desiccator, the reaction temperature is 25°C, and the reaction time is 24h. Part of the film on the surface of the salt solution is taken out and used to remove CO 2 After washing with water three times, it was transferred to a clean silicon substrate for drying at low temperature to obtain a membrane sample. The remaining membrane samples were taken out and washed by centrifugation, dried at 60 °C for 24 h and ground to obtain Ni 2 AlNO 3 LDHs powder.

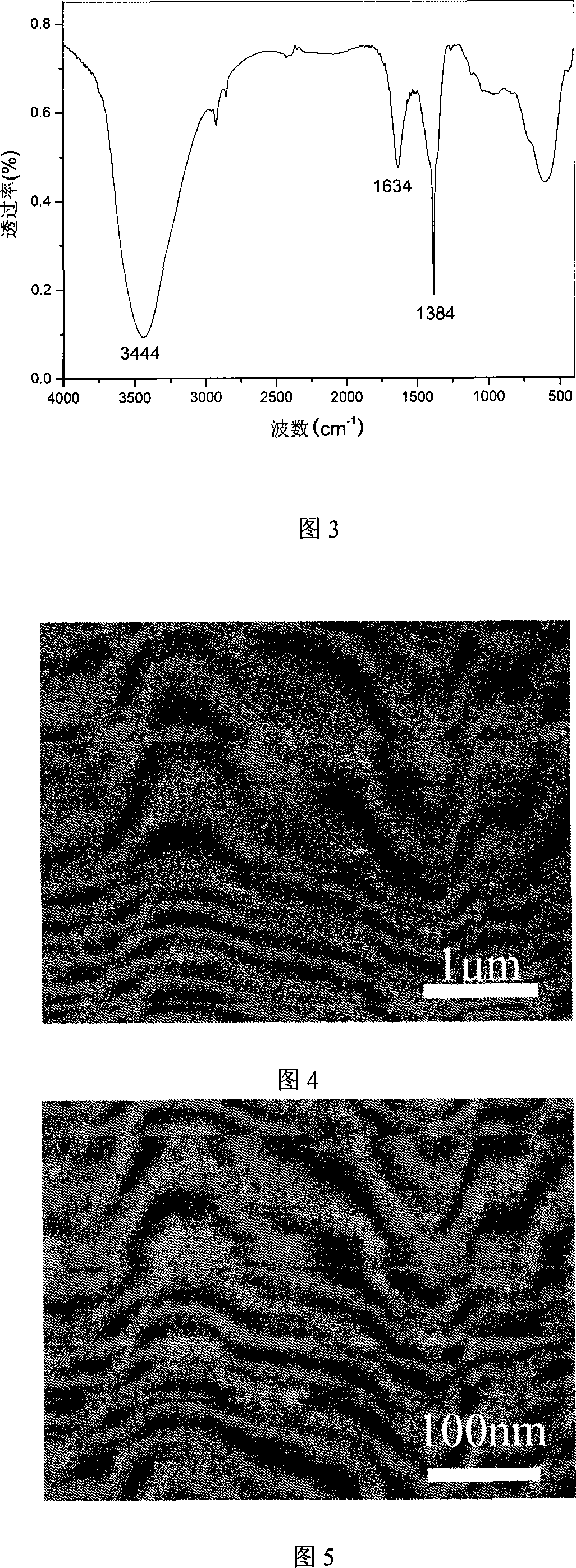

[0026] The IR spectrum of the film powder is at 1384cm -1 The strong an...

Embodiment 2

[0028] Step A: 4.3360g (0.016mol) of solid Zn(NO 3 ) 2 .6H 2 O and 3.0012g (0.008mol) of solid Al(NO 3 ) 3 .9H 2 O dissolved in 80ml of deCO 2 in the water.

[0029] Step B: Measure 2.16ml of concentrated ammonia water with a mass percentage concentration of 28%, and dilute to 80 ml to obtain dilute ammonia water with a mass percentage concentration of 0.68%.

[0030] Step C: Put the mixed salt and lye in different petri dishes, react in a sealed desiccator, the reaction temperature is 25°C, and the reaction time is 24h. Part of the film on the surface of the salt solution is taken out and used to remove CO 2After washing with water three times, it was transferred to a clean silicon substrate for drying at low temperature to obtain a film sample. The remaining membrane samples were taken out and washed by centrifugation, dried at 60°C for 24 hours and ground to obtain Zn 2 AlNO 3 LDHs powder.

[0031] The IR spectrum of the film powder is at 1384cm -1 The strong and...

Embodiment 3

[0033] Step A: 1.1604g (0.004mol) of solid Ni(NO 3 ) 2 .6H 2 O and 0.8080g (0.002mol) of solid Fe(NO 3 ) 3 .9H 2 O dissolved in 80ml of deCO 2 in the water.

[0034] Step B: Measure 1.25ml of concentrated ammonia water with a mass percentage concentration of 28%, and dilute to 20ml to obtain dilute ammonia water with a mass percentage concentration of 1.57%.

[0035] Step C: Put the mixed salt and lye in different petri dishes, react in a sealed desiccator, the reaction temperature is 25°C, and the reaction time is 24h. Part of the film on the surface of the salt solution is taken out and used to remove CO 2 After washing with water three times, it was transferred to a clean silicon substrate for drying at low temperature to obtain a membrane sample. The remaining membrane samples were taken out and washed by centrifugation, dried at 60 °C for 24 h and ground to obtain Ni 2 FeNO 3 LDHs powder.

[0036] The IR spectrum of the film powder is at 1384cm -1 The strong an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com