Process for purifying Cu2+ impurity in zinc electrolytic solution by employing SO2 in smoke gas with by-product of cuprous oxide

A technology for cuprous oxide and zinc purification, applied in copper oxide/copper hydroxide, chemical instruments and methods, neutralized water/sewage treatment, etc., can solve the problem of high treatment costs, achieve significant environmental benefits, reasonable process routes, good market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

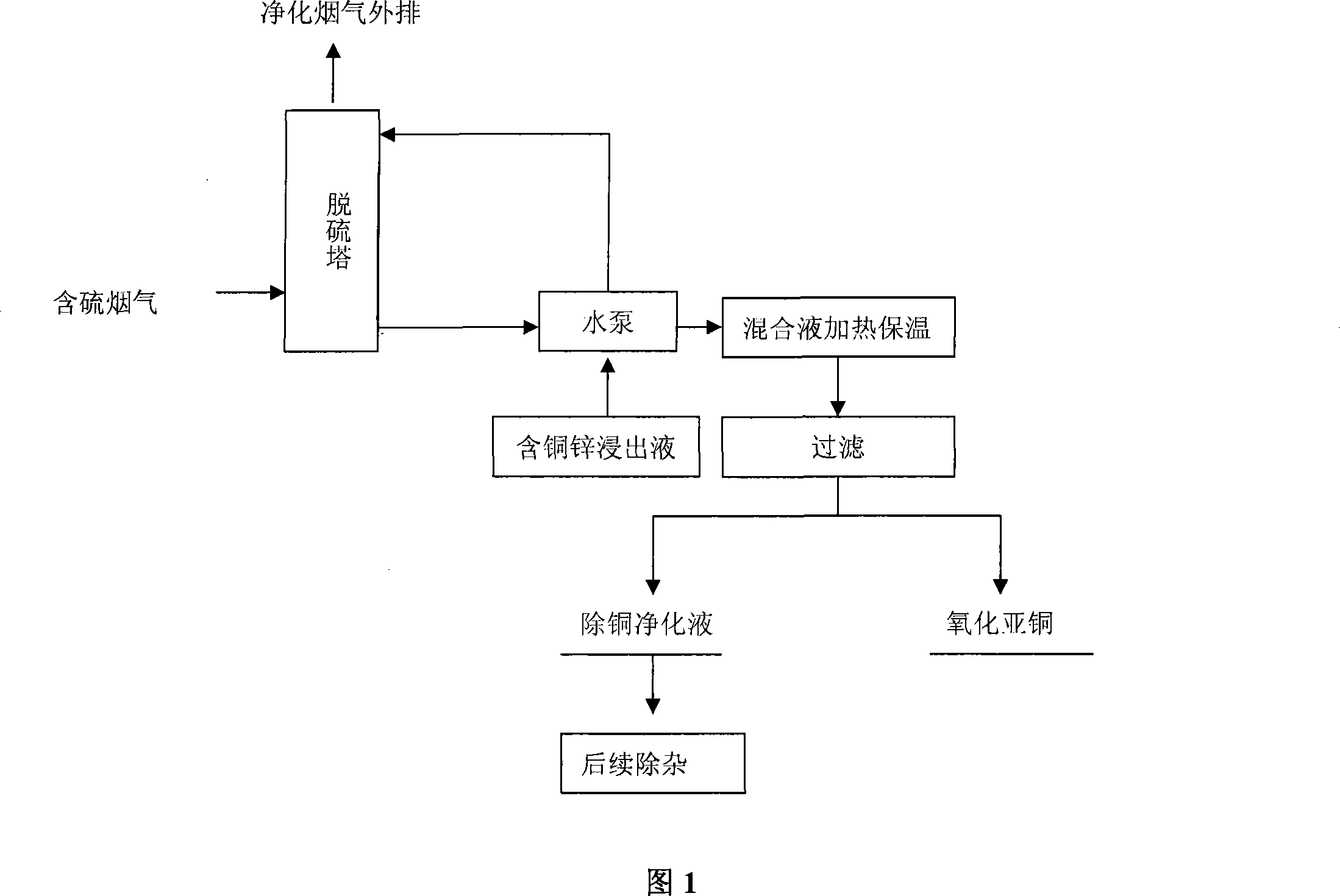

Image

Examples

Embodiment 1

[0021] Referring to Figure 1, first adjust the pH of the zinc leaching solution with a copper ion concentration of 1.2g / L, add zinc oxide powder to it, add and stir, control the pH to 5-6, and let the zinc oxide slightly exceed , Added to the bubbling absorption tower at one time. Displacement of flue gas drawn from a smelter is about 120Nm 3 / h branch, first washed with water to remove dust, and then controlled by the control valve to blow into a bubbling absorption tower, due to air agitation, can avoid suspended solids settling. The present invention performs bubbling reaction under normal pressure and reaction temperature at normal temperature. The residual flue gas after the absorption reaction is directly discharged through the top of the bubbling absorption tower. After the reaction, a large amount of dark red product is produced. The pH is detected When the value is 2.5-3.5, the liquid in the bubble column is pumped into a constant temperature water tank, kept at a constan...

Embodiment 2

[0023] First adjust the pH value of the zinc leaching solution with a copper ion concentration of 2.0g / L, add zinc oxide powder to it, add and stir, control the pH value to 5-6, let the zinc oxide be slightly excessive; adjust the pH value The latter zinc leaching solution containing copper ions is sent to the spray absorption tower. The displacement drawn from the exhaust flue of a smelter is about 1000Nm 3 / h branch, bubbling into a spray absorption tower, the bottom liquid of the absorption tower is pumped out and sent in circulation to repeat absorption. Under the conditions of normal pressure and normal temperature, the absorption reaction is carried out. The residual flue gas after the absorption reaction is directly discharged through the top of the spray tower. After the reaction, a large amount of dark red product is produced at the bottom of the tower. Monitor the pH value At 2.5-3.5 hours, the product is pumped into the thermostatic reaction kettle, and reacted at a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com