Novel process for preparing charcoal/charcoal component by rapid chemical liquid-phase vaporization osmosis method

A technology of gasification infiltration and chemical liquid is applied in the field of rapid preparation of carbon/carbon composite materials, induction heating chemical liquid phase gasification infiltration to prepare carbon/carbon components, and achieves the advantages of shortening the preparation period, improving the utilization rate of raw materials and reducing the preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

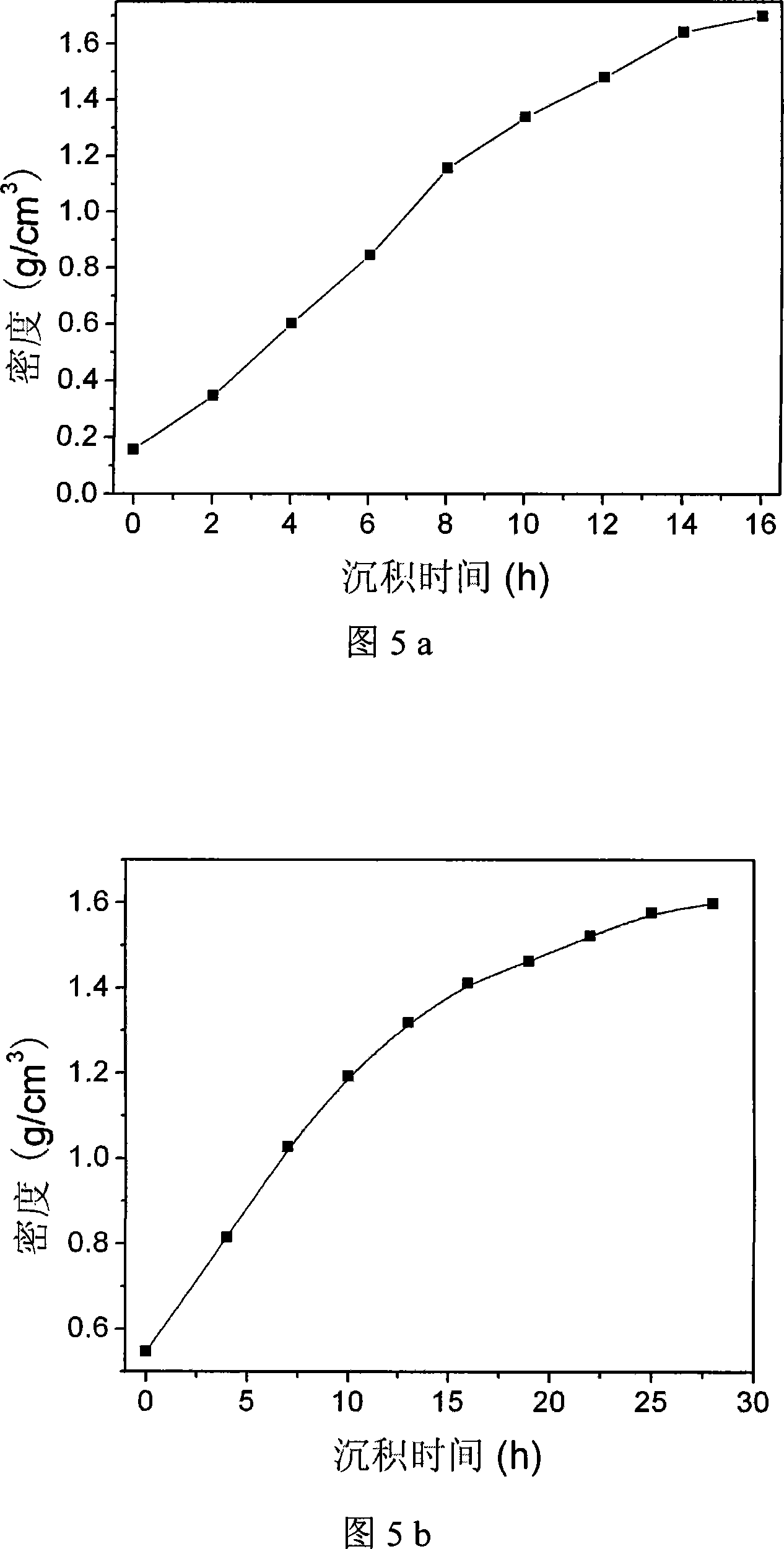

Embodiment 1

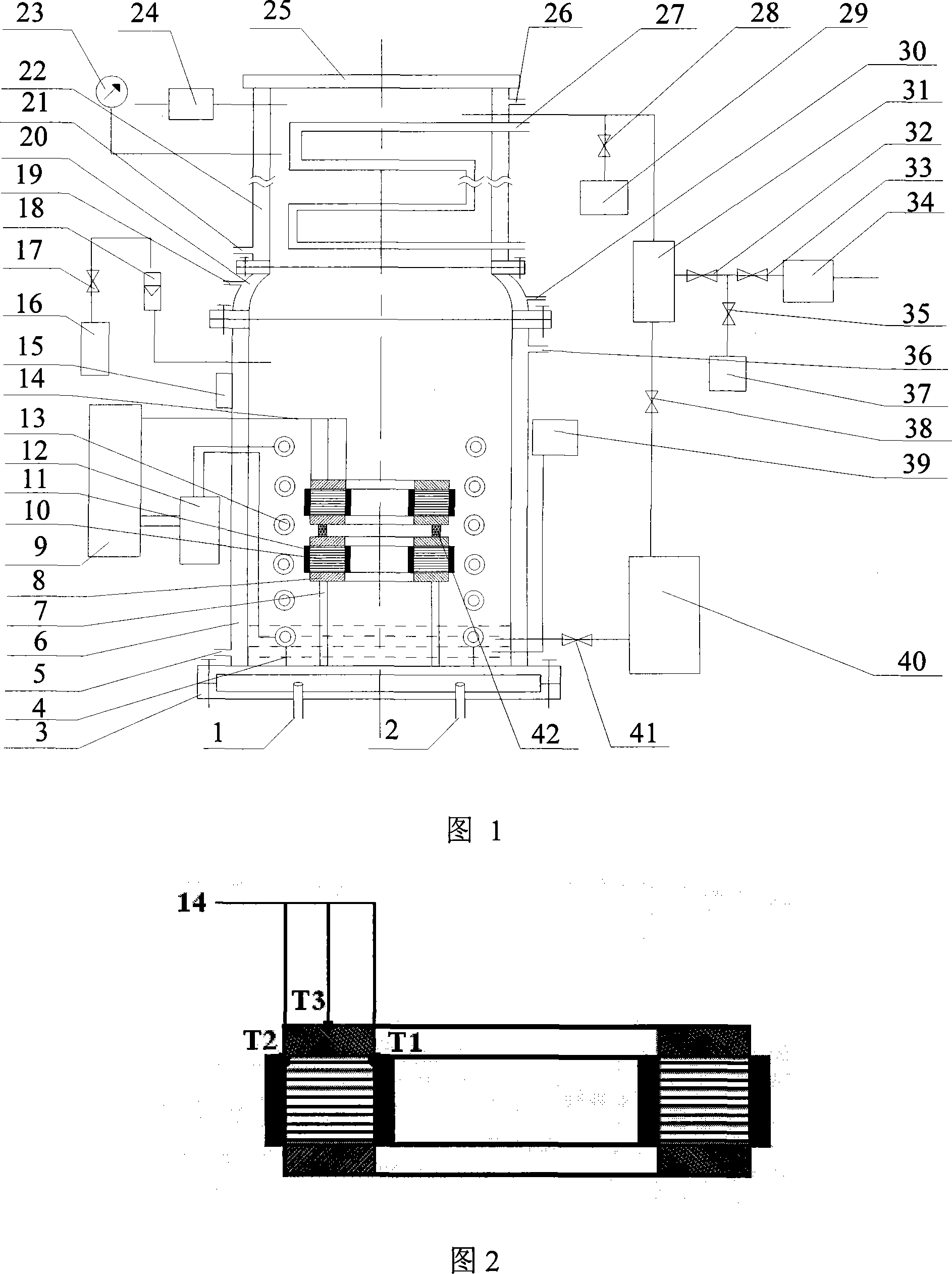

[0068] Embodiment one : The present invention's fast chemical liquid-phase gasification infiltration method prepares the new technology of charcoal / charcoal member:

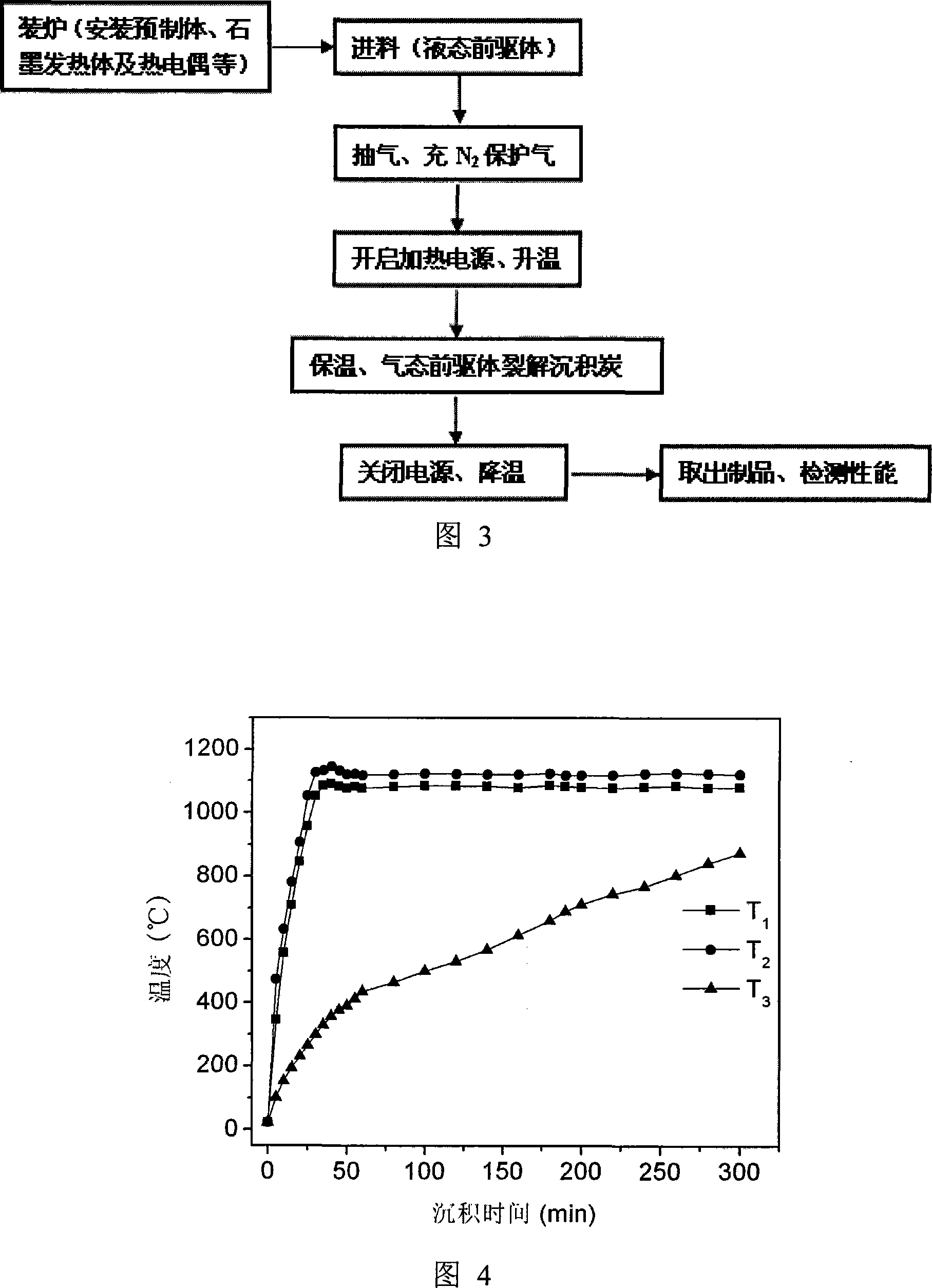

[0069] (1) Carbon felt is used as the carbon / carbon component prefabricated body 8, with an outer diameter of 450mm, an inner diameter of 230mm, a thickness of 20mm, and an initial density of about 0.17g / cm 3 , placed on the upper and lower surfaces of the graphite heating element 10, then put it into the furnace body 6 of the rapid liquid-phase vaporization deposition furnace, and support it with a bracket 7, and use a gasket 42 to separate the two prefabricated bodies in the middle. The thermocouples 14 are respectively installed at three positions as shown in FIG. 2 . Wrap the heat insulating material 11 and cover the furnace cover 20.

[0070] (2) start mechanical vacuum pump 37, vacuumize furnace body 6, when furnace pressure is lower than 5KPa, charge into protective gas 16 (nitrogen N 2 ) to return the ...

Embodiment 2

[0075] Embodiment two : The present invention's fast chemical liquid-phase gasification infiltration method prepares the new technology of charcoal / charcoal member:

[0076] (1) Needle-punched felt is used as the carbon / carbon component preform 8, with an outer diameter of 450mm, an inner diameter of 230mm, a thickness of 20mm, and an initial density of about 0.55g / cm 3 , placed on the upper and lower surfaces of the graphite heating element 10, then put it into the furnace body 6 of the rapid liquid-phase vaporization deposition furnace, and support it with a bracket 7, and use a gasket 42 to separate the two prefabricated bodies in the middle. The thermocouples 14 are respectively installed at three positions as shown in FIG. 2 . Wrap the heat insulating material 11 and cover the furnace cover 20.

[0077] (2) start mechanical vacuum pump 37, vacuumize furnace body 6, when furnace pressure is lower than 5KPa, charge into N 2 Protect the gas 16 to restore the pressure in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com