Iron catalyst, preparation method and its application in synthesizing hydrocarbon reaction

An iron catalyst and catalyst technology, applied in the direction of hydrocarbon production from carbon oxides, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low cooling rate, difficulty in forming grain catalysts, etc., to avoid easy loss, Stable Fischer-Tropsch reaction activity, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

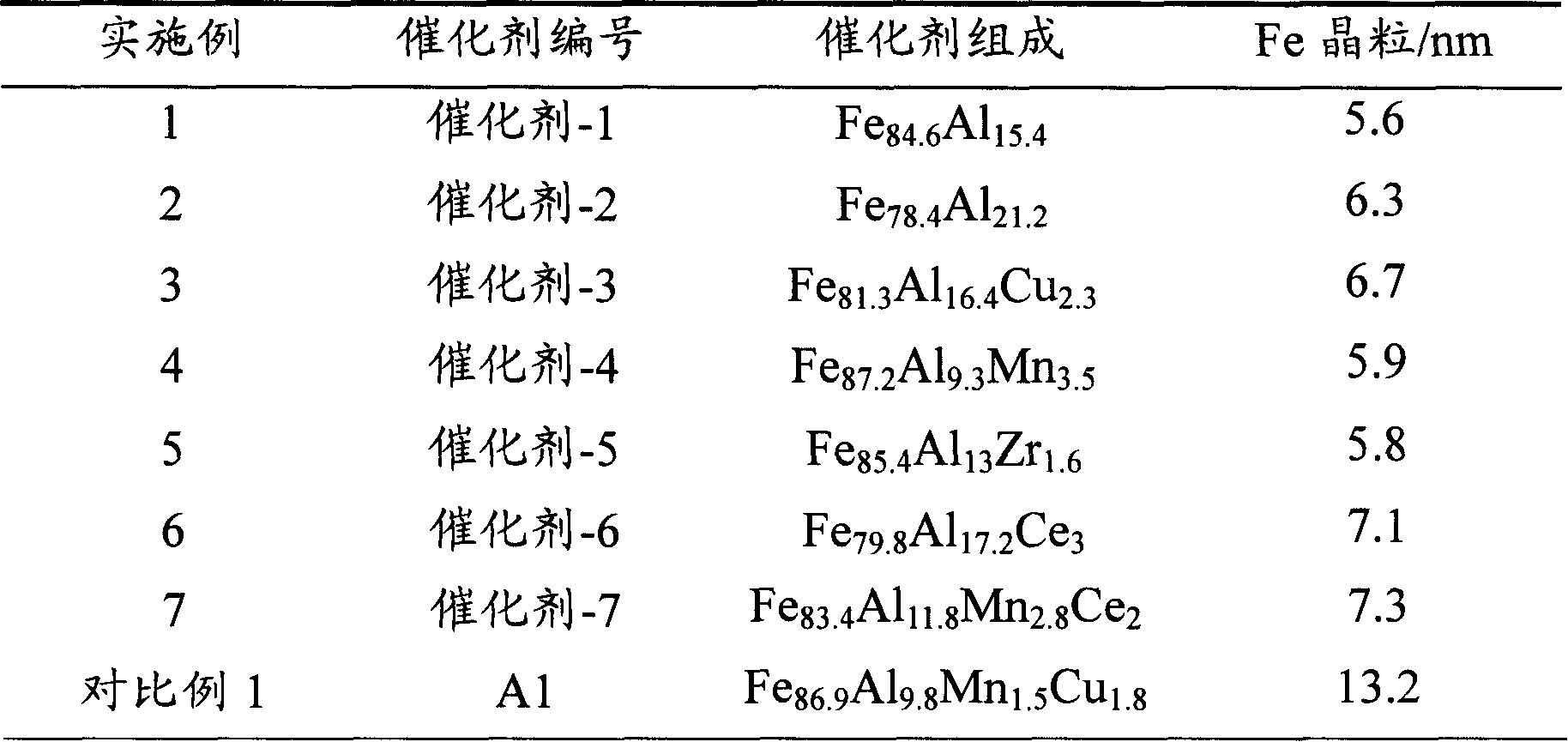

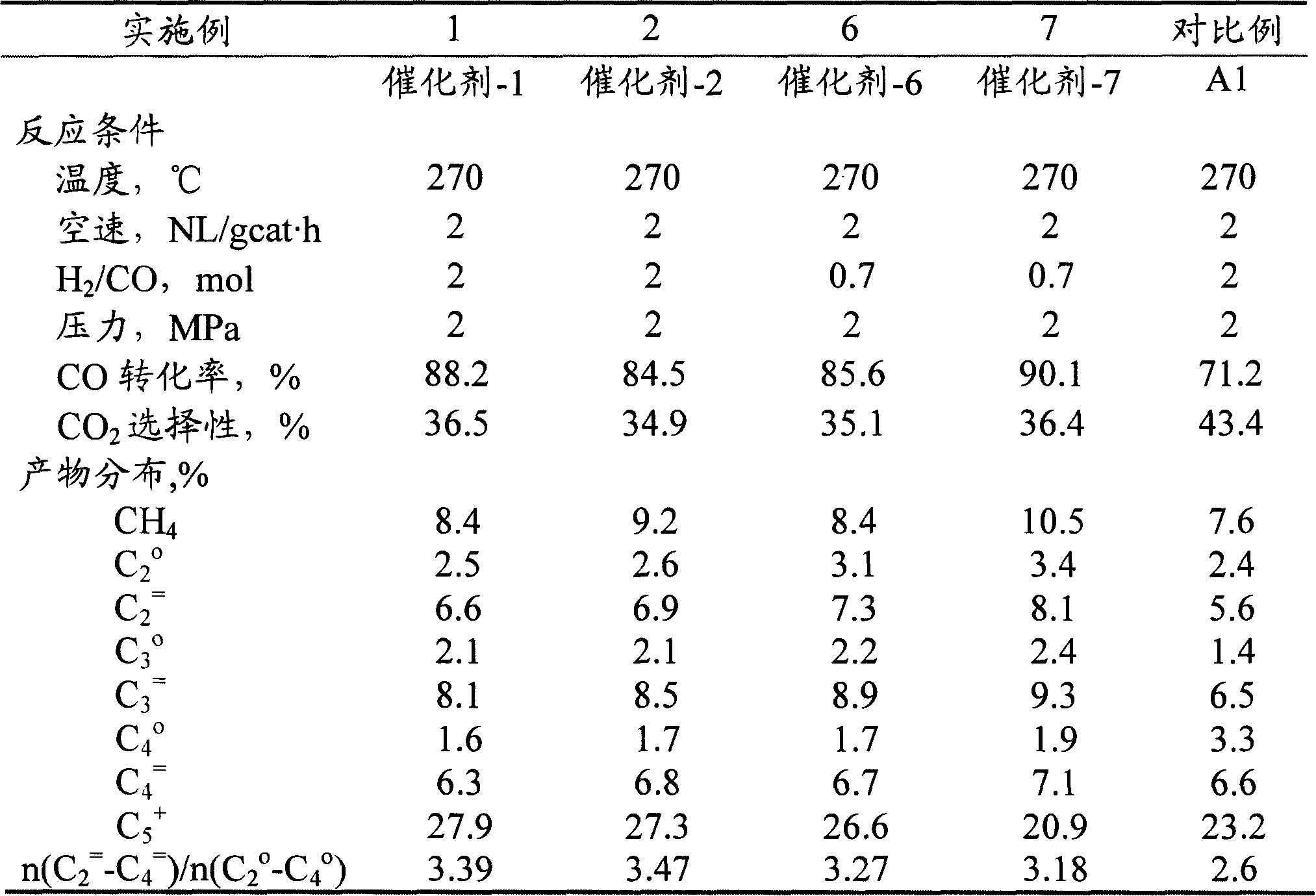

Examples

Embodiment 1

[0032] Add 500g of iron and 500g of aluminum into the graphite crucible, and heat it in a high-frequency furnace to above 1300°C to melt and alloy it, and then use inert gas or hydrogen to spray the alloy liquid from the nozzle of the crucible to a certain speed On the copper roller of 670 rpm, cooling water is passed through the copper roller, and the alloy liquid is 10 6 After rapid cooling at the cooling rate of ℃ / s, it is thrown out along the tangent line of the copper roll to form scale-like strips. The scale-like strips are ground to a particle diameter of less than 50 microns to obtain a master alloy.

[0033] Slowly add 50 g of the master alloy into a three-neck flask filled with 500 g of 20% aqueous sodium hydroxide solution, control its temperature to 80° C. and keep stirring at constant temperature for 1 hour. After stopping heating and stirring, decant the liquid and wash with distilled water at 80°C until the pH value is 7. The prepared catalyst is numbered Catal...

Embodiment 2

[0040] Add 1.0kg of iron and 2.0kg of aluminum into the graphite crucible, heat it in a high-frequency furnace to above 1300°C to melt and alloy it, and then use inert gas or hydrogen to spray the alloy liquid from the nozzle of the crucible to a Rotating speed is on the copper roller of 670 rev / mins, passes cooling water in the copper roller, and alloy liquid is with 10 6 After rapid cooling at the cooling rate of ℃ / s, it is thrown out along the tangent line of the copper roll to form scale-like strips. The scale-like strips are ground to a particle diameter of less than 500 microns to obtain a master alloy.

[0041] Slowly add 50 g of the master alloy into a three-neck flask filled with 500 g of 20% aqueous sodium hydroxide solution, control its temperature to 100° C. and keep stirring at constant temperature for 1 hour. After the heating and stirring were stopped, the liquid was decanted, washed with distilled water at 80°C until the pH value was 7, and the prepared catalys...

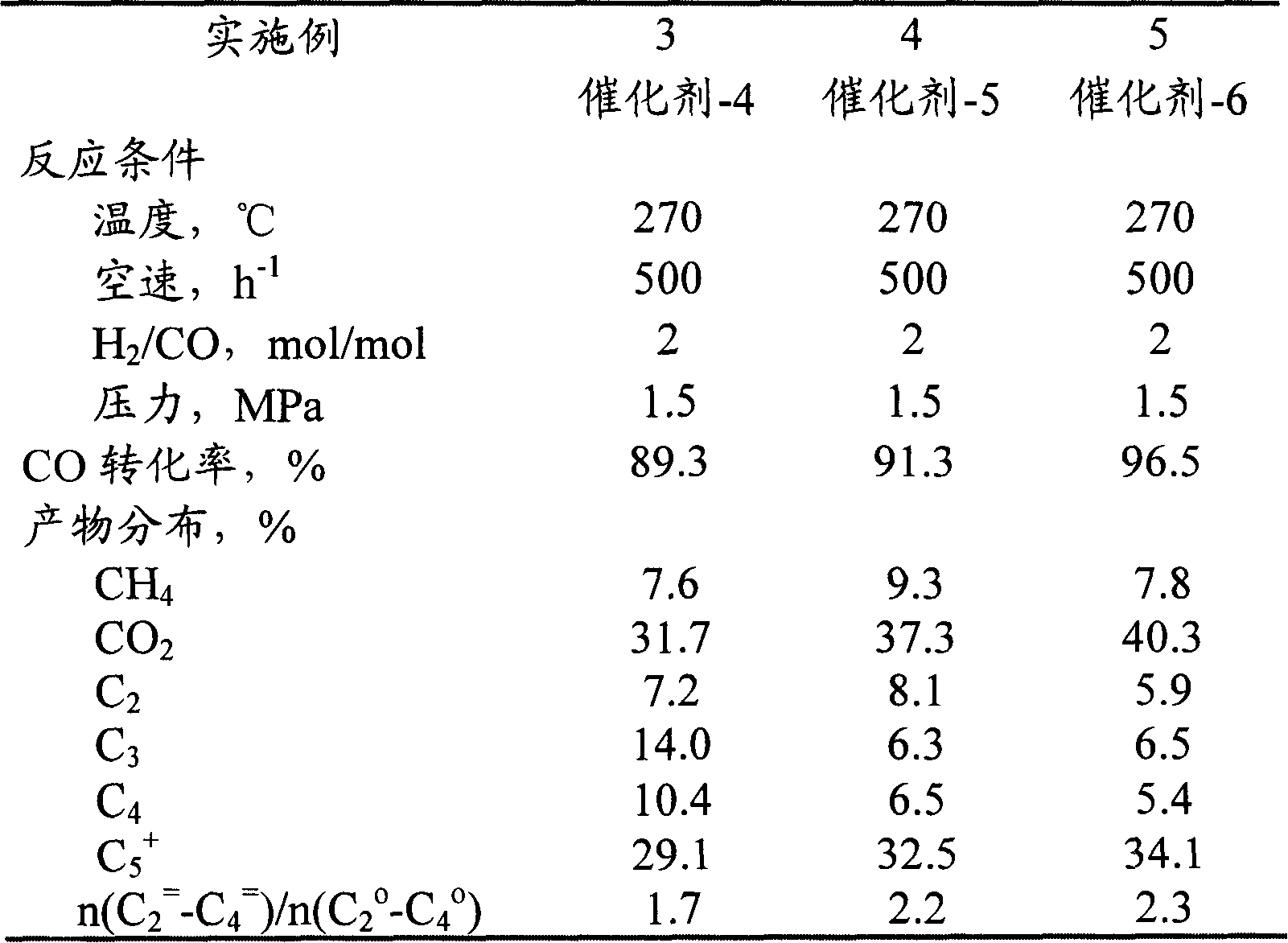

Embodiment 3

[0047] Add 480g of iron, 480g of aluminum and 40g of copper into the graphite crucible, heat it in a high-frequency furnace to above 1600°C and melt it to alloy it, and then use inert gas or hydrogen to spray the alloy liquid from the nozzle of the crucible to the On a copper roll whose rotating speed is 670 rpm, cooling water is passed through the copper roll, and the alloy liquid is cooled by 10 6 The cooling rate of ℃ / s is rapidly cooled and thrown out along the tangent line of the copper roller to form scaly strips, which are ground to a particle diameter of less than 500 microns.

[0048] Then 50 g of the master alloy was slowly added into a three-necked flask filled with 500 g of 20% aqueous sodium hydroxide solution, and the temperature was controlled to be 100° C. and stirred at constant temperature for 1 hour. After stopping heating and stirring, decant the liquid and wash with distilled water at 80°C until the pH value is 7. The prepared catalyst is numbered Catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com