Buckle type electrochemical capacitor and its manufacture method

A supercapacitor and buckle-type technology, which is applied in the field of supercapacitors and its manufacturing, can solve problems affecting the normal operation of supercapacitors, capacity loss, slow electronic conductance, etc., to improve high-current discharge performance, reduce polarization, and reduce internal The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

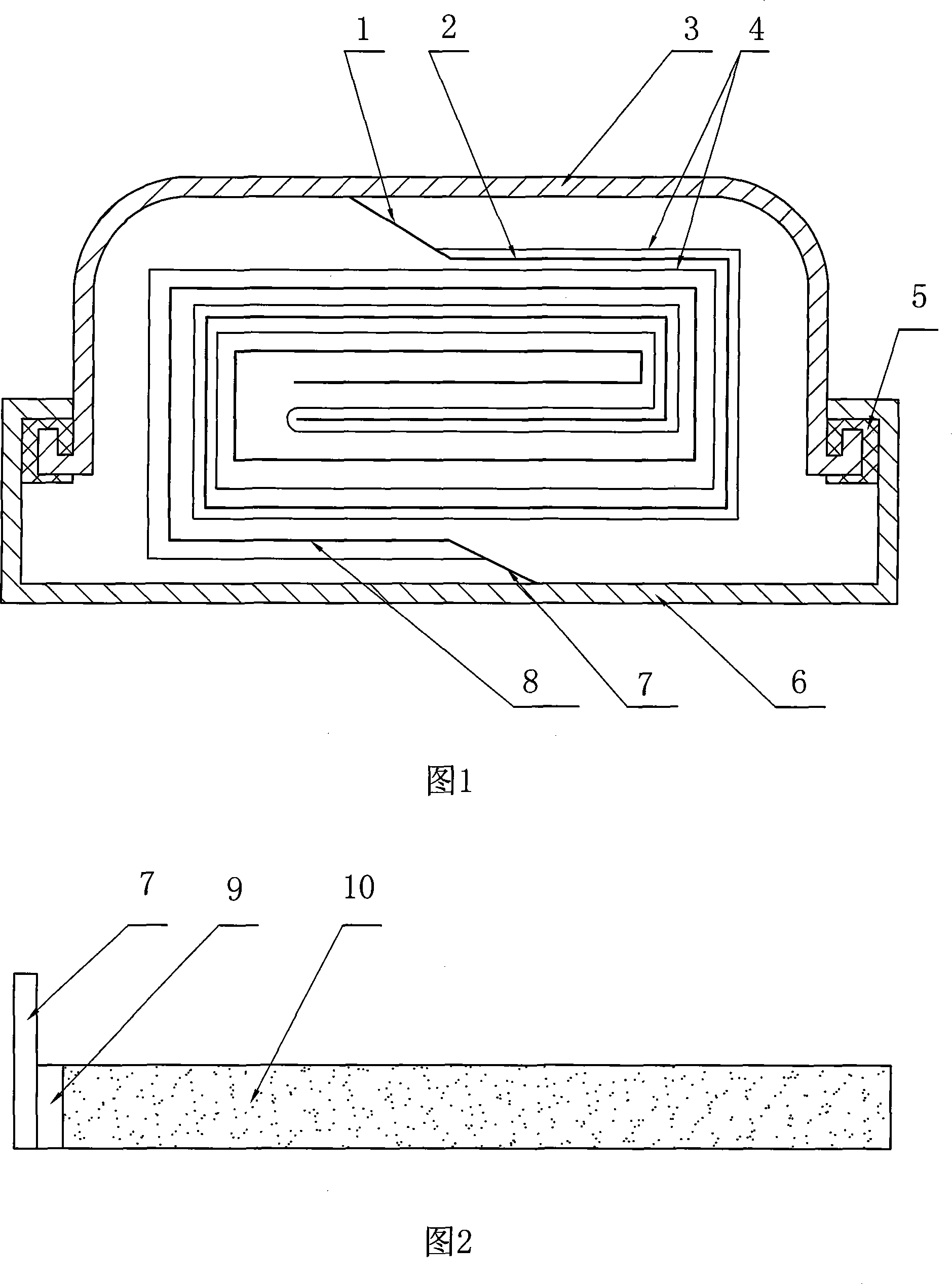

[0093] The button super capacitor of the present invention is manufactured through the following method steps.

[0094] (1) The raw materials are proportioned according to the following parts by weight:

[0095] Porous activated carbon 85;

[0096] Acetylene carbon black 5;

[0097] Homopolyvinylidene fluoride (PVDF) powder 10;

[0098] Production method: first dissolve 10 parts by weight of homopolyvinylidene fluoride (PVDF) powder in 250 parts by weight of nitrogen-methylpyrrolidone (NMP), and then combine 85 parts by weight of porous activated carbon and 5 parts by weight of Acetylene carbon black is mixed, stirred and dispersed to form a uniform slurry.

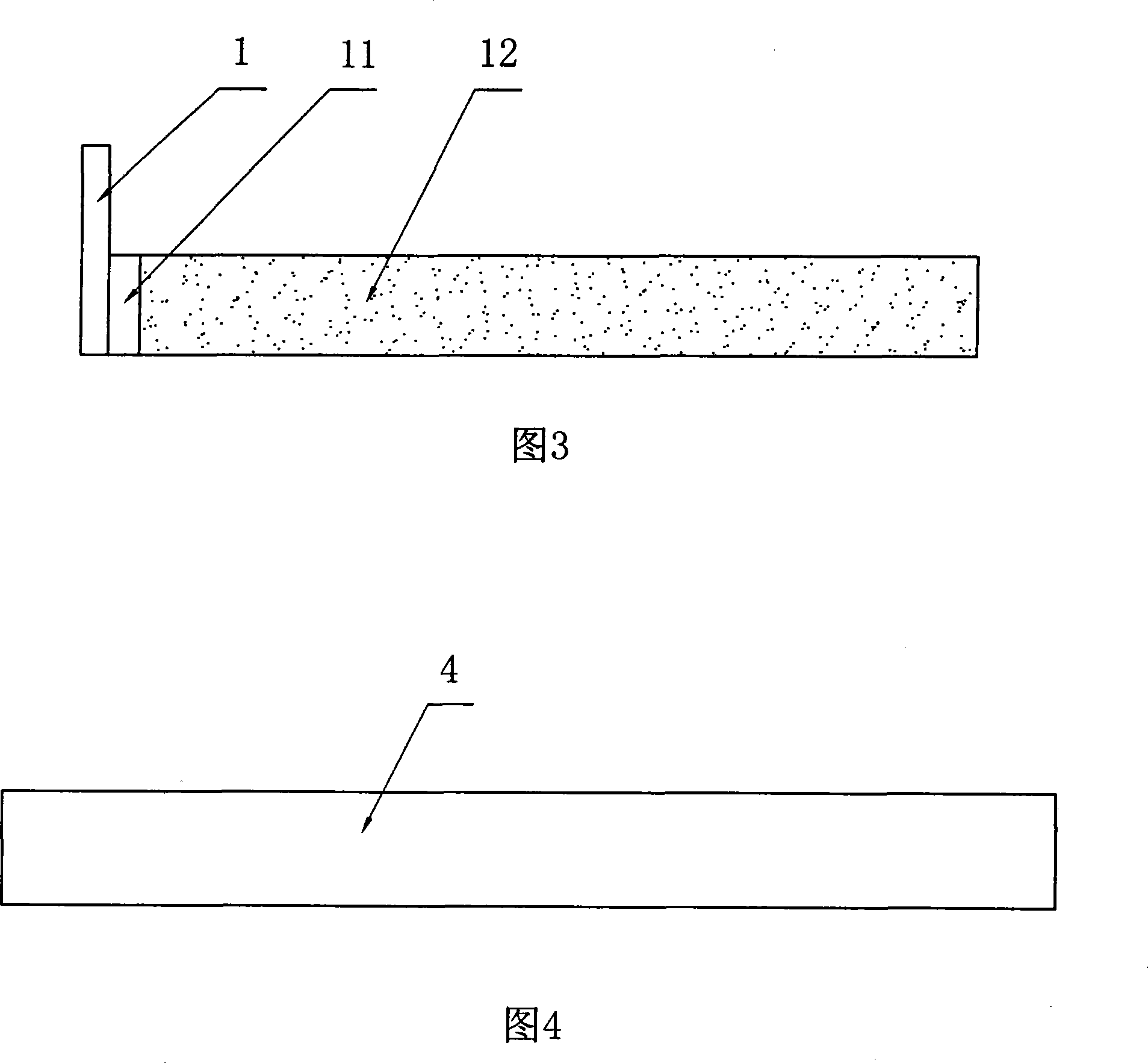

[0099] (2) Use a casting machine to coat the slurry uniformly on the surface of the metal aluminum foil according to the requirements of the electrode size of the manufactured supercapacitor. The coating size can be achieved by controlling the casting machine, and vacuum drying at 130°C for 5-60 minutes ; According to the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com